During the raw material preparation stage, a muffle furnace is utilized primarily for the high-temperature pretreatment of powder materials to ensure chemical purity. Specifically, it is used to heat oxides to temperatures as high as 1000 °C or to subject carbonates to decarbonization, effectively stripping away adsorbed moisture and volatile components before the primary experiment begins.

Core Takeaway The muffle furnace is not just a heating device; it is a stabilization tool. By removing volatile impurities and moisture during the preparation phase, it allows you to lock in the initial chemical composition and oxygen fugacity of your system, ensuring that subsequent experimental data is not skewed by contaminants.

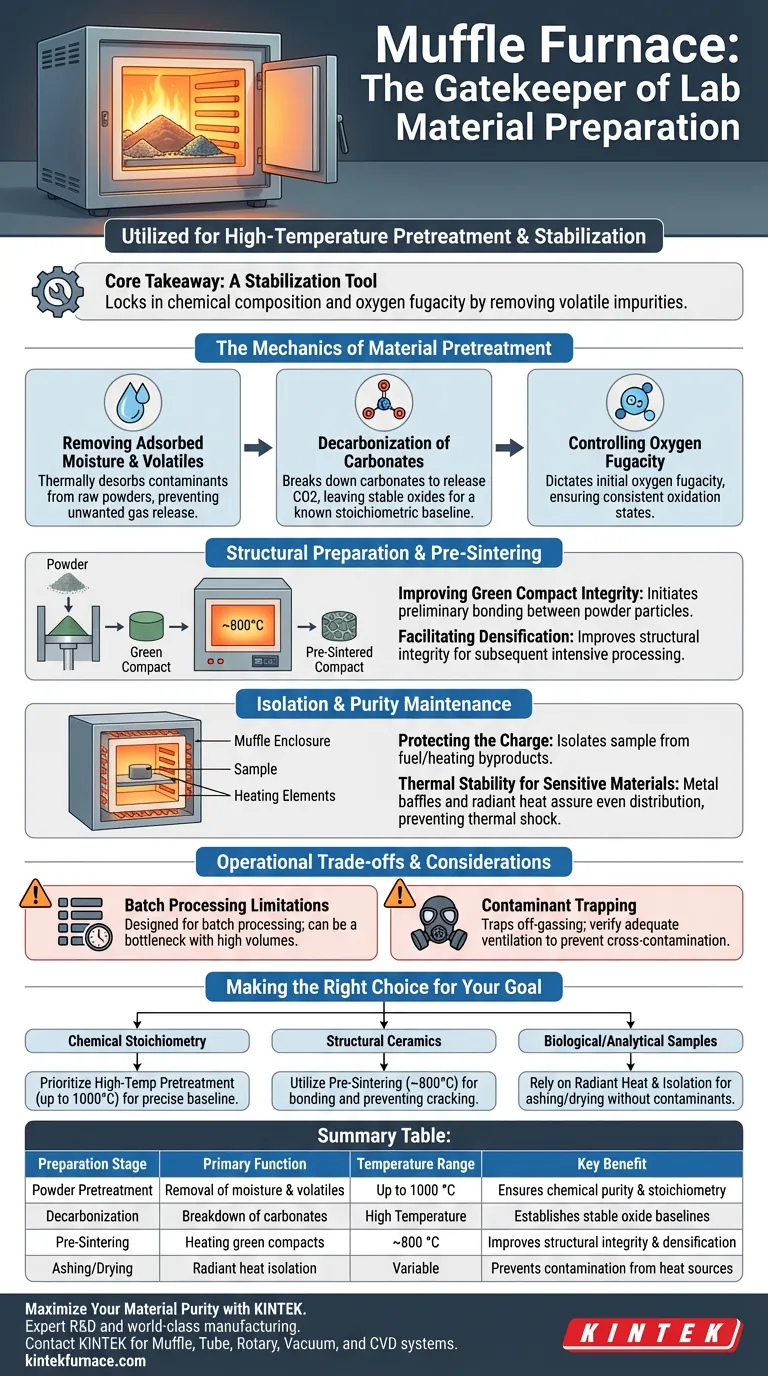

The Mechanics of Material Pretreatment

Removing Adsorbed Moisture and Volatiles

Raw powder materials, particularly oxides, often retain moisture from the atmosphere or manufacturing processes.

Using a muffle furnace during preparation ensures these contaminants are thermally desorption.

This prevents the release of unwanted gases during later, more critical stages of the experiment.

Decarbonization of Carbonates

For experiments involving carbonates, the muffle furnace facilitates decarbonization.

This process breaks down the carbonate structures to release carbon dioxide, leaving behind a chemically stable oxide.

This step is essential for establishing a known stoichiometric baseline for the reaction system.

Controlling Oxygen Fugacity

Precise control over the chemical environment is vital for reproducibility.

By pretreating materials in a muffle furnace, researchers can dictate the initial oxygen fugacity (the effective partial pressure of oxygen) of the sample.

This ensures that the oxidation state of the elements remains consistent with the experimental design.

Structural Preparation and Pre-Sintering

Improving Green Compact Integrity

Beyond loose powders, the furnace is utilized for cold-pressed "green compacts" (materials pressed into shape but not yet fired).

Heating these compacts to a predetermined intermediate temperature (e.g., 800 °C) initiates preliminary bonding between powder particles.

Facilitating Densification

This pre-sintering step improves the structural integrity of the material.

It prepares the sample for subsequent high-pressure hot re-pressing or full sintering.

Without this step, the material might lack the mechanical stability required for intensive processing.

Isolation and Purity Maintenance

Protecting the Charge

The defining feature of a muffle furnace is the "muffle" itself—an enclosure that isolates the sample from direct contact with heating elements or combustion flames.

This is critical during preparation to prevent contamination from the furnace's own fuel or heating byproducts.

Thermal Stability for Sensitive Materials

Biological samples or sensitive chemical compounds require an environment free from rapid thermal fluctuations.

The muffle furnace uses metal baffles and radiant heat transfer to distribute energy evenly.

This allows for the preparation of highly sensitive materials without the risk of thermal shock or uneven heating.

Operational Trade-offs and Considerations

Batch Processing Limitations

Muffle furnaces are typically designed for batch processing rather than continuous flow.

This means the preparation stage can become a bottleneck if you are working with high volumes of raw material.

You must plan your experimental timeline to account for heat-up and cool-down cycles.

Contaminant Trapping

While the muffle protects the sample from the heat source, it also contains any off-gassing from the sample itself.

If you are burning out binders or volatiles, adequate ventilation or exhaust systems must be verified.

Failure to vent these volatiles can lead to cross-contamination between samples within the same batch.

Making the Right Choice for Your Goal

When utilizing a muffle furnace for preparation, your specific objective should dictate your protocol:

- If your primary focus is Chemical Stoichiometry: Prioritize high-temperature pretreatment (up to 1000 °C) to ensure total removal of moisture and carbonates for a precise compositional baseline.

- If your primary focus is Structural Ceramics: Utilize the furnace for pre-sintering at moderate temperatures (around 800 °C) to bond particles and prevent cracking during final densification.

- If your primary focus is Biological/Analytical Samples: Rely on the furnace’s radiant heat and isolation capabilities to ash samples or dry materials without introducing combustion contaminants.

The muffle furnace is the gatekeeper of your experiment's integrity; proper use during preparation eliminates variables before they can become errors.

Summary Table:

| Preparation Stage | Primary Function | Temperature Range | Key Benefit |

|---|---|---|---|

| Powder Pretreatment | Removal of moisture & volatiles | Up to 1000 °C | Ensures chemical purity & stoichiometry |

| Decarbonization | Breakdown of carbonates | High Temperature | Establishes stable oxide baselines |

| Pre-Sintering | Heating green compacts | ~800 °C | Improves structural integrity & densification |

| Ashing/Drying | Radiant heat isolation | Variable | Prevents contamination from heat sources |

Maximize Your Material Purity with KINTEK

Don't let impurities compromise your experimental data. Backed by expert R&D and world-class manufacturing, KINTEK provides high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems designed for the rigorous demands of laboratory preparation. Whether you need standard high-temperature pretreatment or a fully customizable furnace for unique stoichiometric needs, our team delivers the precision you require.

Ready to elevate your lab's efficiency? Contact KINTEK today to find your perfect thermal solution!

Visual Guide

References

- Wanying Wang, Yuan Li. Redox control of the partitioning of platinum and palladium into magmatic sulfide liquids. DOI: 10.1038/s43247-024-01366-y

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- How does the temperature control system of a muffle furnace work? Achieve Precise Thermal Processing for Your Lab

- What is the role of a muffle furnace in the calcination of Co@BaAl2O4-x catalyst? Key Steps for Precision Synthesis

- What role does a high-temperature muffle furnace play in the preparation of acid-activated clay? Key Thermal Mechanisms

- Why does the edge of a workpiece reach higher temperatures than its center? Master Thermal Uniformity in Sintering

- What role does a muffle furnace play in g-C3N4 synthesis? Mastering Thermal Polycondensation for Semiconductors

- Why is a high-temperature muffle furnace required for U3O8 preparation? Achieving Phase Purity and Stability

- What are the steps to operate a box muffle furnace? Master Safe and Efficient Heating Processes

- How is a muffle furnace utilized in research and medical laboratories? Essential for Contaminant-Free High-Temperature Processing