At its core, a box-type electric furnace is a precisely engineered system composed of four primary structural and operational components. These are the furnace body which provides the physical structure, the heating elements that generate the heat, the insulation that contains it, and the temperature control system that manages the entire process.

A box-type furnace is not merely a heated box; it is a balanced system where each component—from the steel shell to the PID controller—works in concert to create a stable, uniform, and high-temperature environment for material processing.

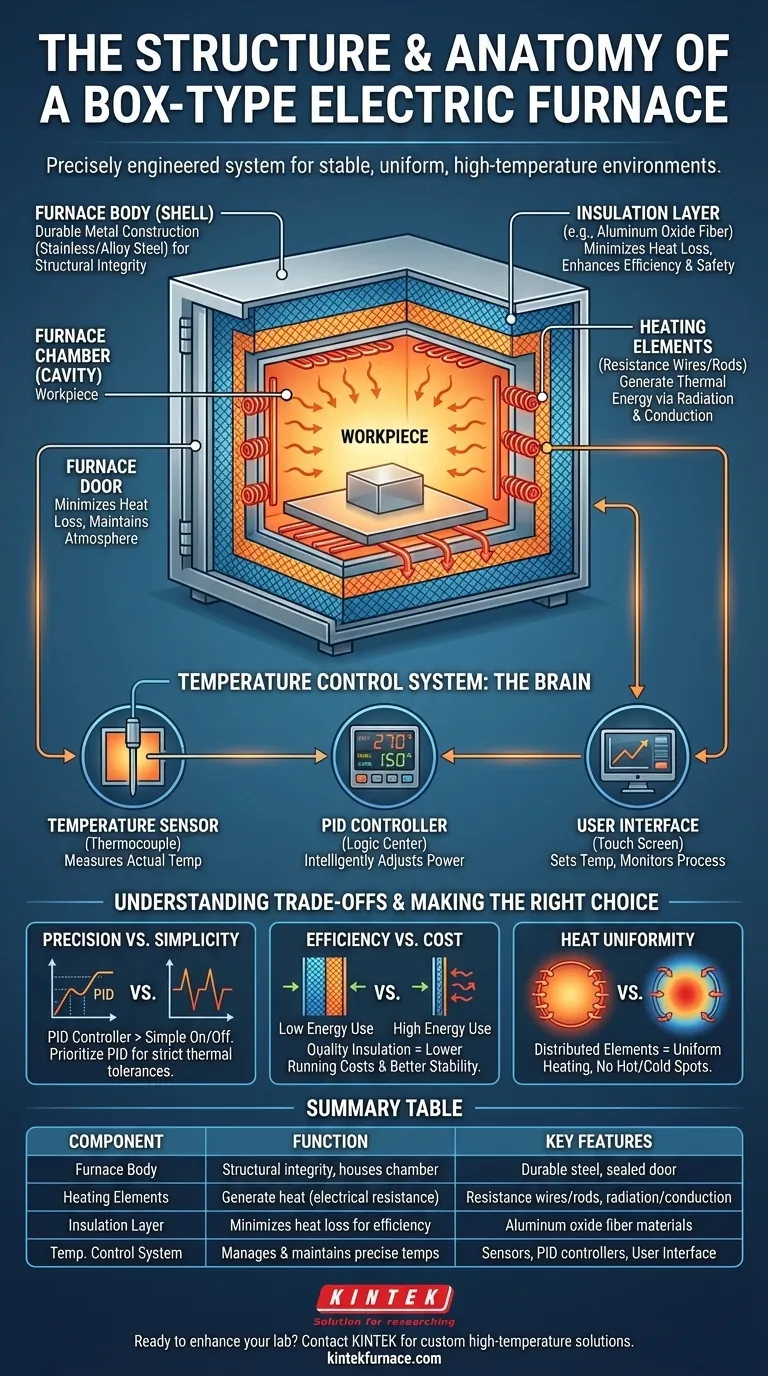

The Anatomy of a Box-Type Furnace

To understand how these furnaces achieve precise heating, we must examine the function of each core component. The design is a direct reflection of its purpose: generating and containing thermal energy efficiently.

The Furnace Body and Chamber

The furnace body, also called the shell, is the external framework. It is typically constructed from durable metal like stainless or alloy steel to provide structural integrity and withstand the high operational temperatures over long periods.

Inside this body is the furnace chamber or cavity. This is the insulated internal space where workpieces are placed and heated. Access is provided by a tightly sealed furnace door, which is critical for minimizing heat loss and maintaining a stable internal atmosphere.

The Heating Elements: The Engine of Heat

Heating elements are the active components responsible for generating thermal energy. These are most often resistance wires or rods that convert electrical energy directly into heat.

They are strategically installed within the furnace chamber to ensure heat is delivered to the workpiece. The primary methods of heat transfer inside the furnace are thermal radiation and conduction.

The Insulation Layer: Containing the Energy

Surrounding the furnace chamber is a thick layer of insulation material, such as aluminum oxide fiber. This component is non-negotiable for performance and safety.

Its sole purpose is to minimize heat loss to the external environment. Effective insulation ensures the furnace operates efficiently, reaches temperature quickly, and maintains a stable internal climate without consuming excessive power.

The Temperature Control System: The Brain of the Operation

This is the most sophisticated part of the furnace. It is an integrated system that ensures the temperature you set is the temperature you get, accurately and consistently.

It consists of three key parts:

- Temperature Sensors (e.g., thermocouples): These act as the nerves, constantly measuring the actual temperature inside the chamber.

- PID Controllers: This is the logic center. A Proportional-Integral-Derivative (PID) controller continuously calculates the difference between the setpoint and the actual temperature and intelligently adjusts power to the heating elements.

- User Interface (e.g., touch screen): This allows the operator to set the desired temperature, monitor the process, and program heating cycles.

Understanding the Trade-offs

A furnace's performance is a direct result of how well its components are integrated. Simply having all the parts is not enough; their quality and interaction determine the outcome.

Precision vs. Simplicity in Control

An advanced PID controller is superior to a simple on/off thermostat because it prevents temperature overshooting and undershooting. For applications requiring strict thermal tolerances, the quality of the controller is paramount. A simpler system may be cheaper but will not provide a stable temperature.

Efficiency vs. Cost in Insulation

The quality and thickness of the insulation material directly impact energy consumption. A furnace with superior insulation will have lower running costs and better temperature stability. Skimping on insulation leads to constant heat loss, forcing the heating elements to work harder and wasting electricity.

The Challenge of Heat Uniformity

The placement of heating elements is critical. If they are only located in one area, the furnace will have "hot spots" and "cold spots," leading to uneven treatment of the workpiece. High-quality furnaces distribute elements on multiple sides of the chamber to create a uniform heating environment.

Making the Right Choice for Your Application

Use your understanding of this structure to evaluate a furnace based on its intended purpose.

- If your primary focus is precision and repeatability: Prioritize the sophistication of the temperature control system, ensuring it uses a high-quality PID controller.

- If your primary focus is energy efficiency and lower operating costs: Scrutinize the specifications of the insulation material and the construction of the door seal.

- If your primary focus is durability and high-temperature work: Examine the construction of the furnace body, prioritizing heavy-gauge stainless or high-temperature alloy steel.

Understanding this structure empowers you to evaluate any box-type furnace not just by its specifications, but by how well its components work together to achieve your goal.

Summary Table:

| Component | Function | Key Features |

|---|---|---|

| Furnace Body | Provides structural integrity and houses the chamber | Made of durable steel, includes a sealed door |

| Heating Elements | Generate heat through electrical resistance | Use resistance wires/rods, enable radiation/conduction |

| Insulation Layer | Minimizes heat loss for efficiency | Made of materials like aluminum oxide fiber |

| Temperature Control System | Manages and maintains precise temperatures | Includes sensors, PID controllers, and user interfaces |

Ready to enhance your lab's capabilities with a custom high-temperature furnace? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced solutions tailored to your needs. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization to meet your unique experimental requirements. Contact us today to discuss how we can bring precision and efficiency to your material processing!

Visual Guide

Related Products

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

People Also Ask

- How does a laboratory high-temperature box furnace assist in evaluating concrete fire resistance? | KINTEK

- What is the role of a muffle furnace in synthesizing P2-Na0.67Ni0.33Mn0.67O2? Key to High-Performance Cathodes

- Why is immediate water-quenching required after thermal simulation? Preserve (CoCrNi)94Al3Ti3 Alloy Microstructure

- What is the significance of the thermal environment in calcination? Achieve Pure Ceramic Phases with KINTEK

- How is a laboratory muffle furnace utilized during the debinding stage of HAp green bodies? Precision Thermal Control