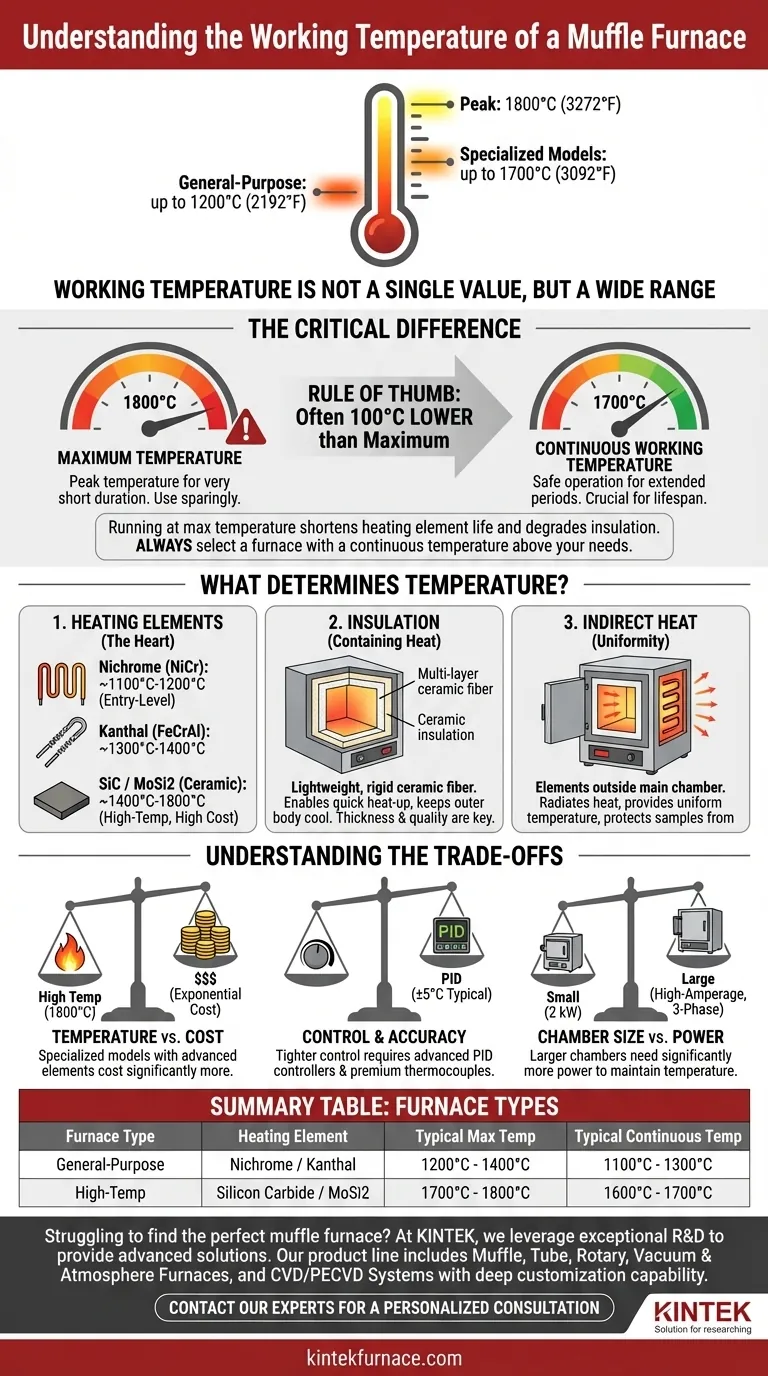

The working temperature of a muffle furnace is not a single value, but a wide range that depends entirely on the specific model and its intended application. While general-purpose lab furnaces operate up to 1200°C (2192°F), specialized models can safely and continuously run at temperatures as high as 1700°C (3092°F) or even reach peaks of 1800°C (3272°F).

The most critical factor is not the advertised maximum temperature, but the continuous working temperature. This value, typically 100°C below the maximum, represents the highest temperature a furnace can safely maintain for extended periods without damaging its internal components.

What Determines a Muffle Furnace's Temperature?

A furnace's temperature capability is a direct result of its engineering and material science. Several key components dictate how hot it can get and for how long.

The Role of Heating Elements

The heart of the furnace is its heating element. The material used for these elements is the primary limiting factor for its temperature range.

- Nichrome (Nickel-Chromium): Common in entry-level and general-purpose furnaces, Nichrome wire is reliable and cost-effective for temperatures up to about 1100°C-1200°C.

- Kanthal (FeCrAl): These iron-chromium-aluminum alloys are a step up, allowing for higher operating temperatures, often up to 1300°C or 1400°C.

- Silicon Carbide (SiC) / Molybdenum Disilicide (MoSi2): For high-temperature applications (1400°C to 1800°C), furnaces use these advanced ceramic elements, which can withstand extreme heat but come at a significantly higher cost.

The Importance of Insulation

Containing extreme heat is just as important as generating it. Modern muffle furnaces use rigid, lightweight ceramic fiber insulation.

This material offers excellent thermal efficiency, allowing the furnace to reach high temperatures quickly while keeping the outer steel body cool to the touch. The quality and thickness of this insulation are critical for temperature stability and energy efficiency.

The Principle of Indirect Heat

A muffle furnace works by indirect heating. The heating elements are located outside the main chamber, separated by the insulating "muffle."

Heat radiates into the chamber, providing a highly uniform temperature and, most importantly, protecting the sample from any contamination from the heating elements. This is essential for processes like ashing or materials analysis where sample purity is paramount.

The Critical Difference: Maximum vs. Continuous Working Temperature

Understanding the distinction between these two specifications is crucial for both achieving accurate results and preserving the life of the furnace.

Maximum Temperature

This is the peak temperature the furnace can technically reach for a very short duration. Pushing a furnace to its maximum should be done sparingly, if at all.

Continuous Working Temperature

This is the most important specification. It is the temperature the furnace is designed to operate at safely and reliably for extended cycles, such as overnight sintering or ashing processes. As a rule of thumb, this is often 100°C lower than the stated maximum temperature.

Why This Distinction Matters

Consistently running a furnace at its absolute maximum temperature will drastically shorten the lifespan of its heating elements and can degrade the insulation over time. This leads to costly repairs and unreliable performance. Always select a furnace whose continuous working temperature comfortably exceeds your process requirements.

Understanding the Trade-offs

Choosing a muffle furnace involves balancing performance, longevity, and cost.

Higher Temperature vs. Cost

The relationship between temperature and cost is exponential. A furnace rated for 1200°C is a standard piece of lab equipment. In contrast, a furnace capable of reaching 1700°C or 1800°C is a specialized, high-cost instrument due to its advanced elements and construction.

Temperature Control and Accuracy

Most modern furnaces feature digital PID (Proportional-Integral-Derivative) controllers for precise temperature management. A typical accuracy is around ±5°C, which is sufficient for most applications. If your process requires tighter control, you will need to look for models with more advanced controllers and premium thermocouples (like K-type or S-type sensors).

Chamber Size vs. Power

A larger internal chamber requires significantly more power to reach and maintain temperature. A small benchtop unit may run on a standard 2 kW circuit, while larger industrial models require dedicated high-amperage, three-phase power.

How to Select the Right Furnace for Your Application

Base your choice on the sustained temperature your process demands, not on an aspirational peak value.

- If your primary focus is general lab use (ashing, drying, heat treating below 1100°C): A standard furnace with Nichrome or Kanthal heating elements provides the best balance of performance and cost.

- If your primary focus is advanced materials (sintering, calcination, research above 1200°C): You must select a furnace whose continuous working temperature explicitly meets or exceeds your process needs.

- If your primary focus is process precision: Prioritize a model with a multi-segment programmable digital controller and a specified accuracy rating that aligns with your quality standards.

Matching the furnace's continuous working temperature to your specific thermal process is the key to achieving reliable results and ensuring a long service life for your equipment.

Summary Table:

| Furnace Type | Heating Element | Typical Max Temp | Typical Continuous Temp |

|---|---|---|---|

| General-Purpose | Nichrome / Kanthal | 1200°C - 1400°C | 1100°C - 1300°C |

| High-Temp | Silicon Carbide / MoSi2 | 1700°C - 1800°C | 1600°C - 1700°C |

Struggling to find a muffle furnace that perfectly matches your process temperature and application requirements?

At KINTEK, we leverage our exceptional R&D and in-house manufacturing to provide diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet your unique experimental and production needs—ensuring the continuous working temperature, chamber size, and control accuracy are perfectly tailored for your success.

Contact our experts today for a personalized consultation and let us engineer the ideal thermal solution for your lab.

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- How does a laboratory muffle furnace facilitate the biomass carbonization process? Achieve Precise Biochar Production

- What is the primary function of a muffle furnace for BaTiO3? Master High-Temp Calcination for Ceramic Synthesis

- What environmental conditions are critical for SiOC ceramicization? Master Precise Oxidation & Thermal Control

- What substances are prohibited from being introduced into the furnace chamber? Prevent Catastrophic Failure

- What role does a muffle furnace play in the preparation of MgO support materials? Master Catalyst Activation