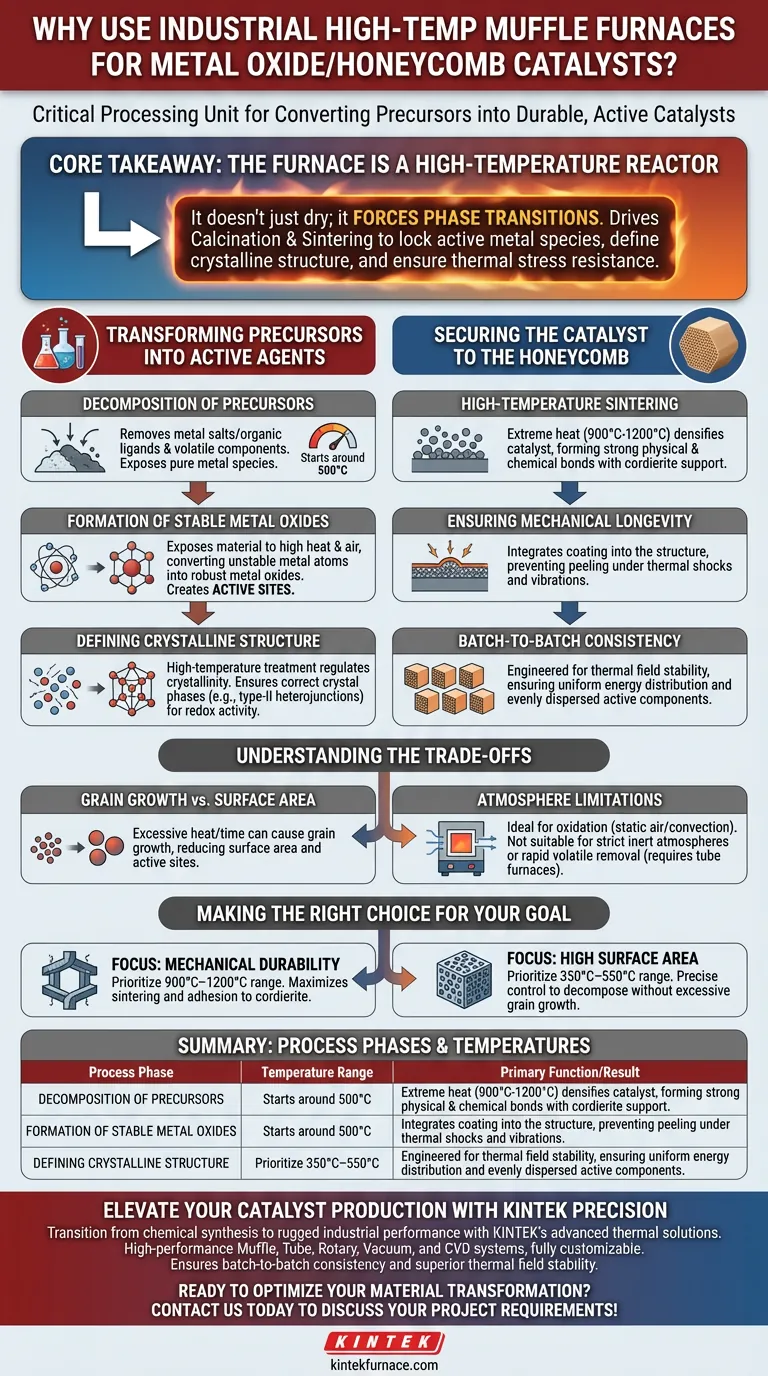

Industrial high-temperature muffle furnaces are the critical processing unit for converting raw chemical precursors into durable, active metal oxide catalysts. They provide the precise thermal environment necessary to drive solid-phase thermochemical reactions, ensuring that metal precursors chemically bond with the honeycomb substrate and transform into stable oxide phases capable of withstanding industrial use.

Core Takeaway: The muffle furnace does not merely dry the material; it acts as a high-temperature reactor that forces phase transitions. It drives the calcination and sintering processes required to lock active metal species onto the substrate, defining the catalyst's crystalline structure and ensuring it resists peeling or deactivation under thermal stress.

Transforming Precursors into Active Agents

To create a functional catalyst, you must move beyond simple mixture and achieve chemical transformation. The muffle furnace facilitates this through controlled thermal application.

Decomposition of Precursors

Raw catalyst materials often begin as metal salts (such as nitrates or acetates) or slurries. The furnace provides a stable oxidative environment, often starting around 500°C, to decompose these precursors. This step burns off organic ligands and volatile components, leaving behind the pure metal species.

Formation of Stable Metal Oxides

Once precursors are decomposed, the furnace drives the oxidation process. By exposing the material to high temperatures in air, it converts unstable metal atoms into robust metal oxides. This phase change is essential for creating the active sites responsible for catalytic reactions.

Defining Crystalline Structure

The specific arrangement of atoms determines a catalyst's efficiency. High-temperature treatment regulates the crystallinity of the material. By adhering to a specific temperature curve, the furnace ensures the formation of the correct crystal phases (such as type-II heterojunctions), which directly influences redox activity.

Securing the Catalyst to the Honeycomb

For honeycomb catalysts (often using cordierite substrates), the physical attachment of the active material is as important as its chemical composition.

High-Temperature Sintering

According to primary industrial standards, temperatures ranging from 900°C to 1200°C are often required for final processing. This extreme heat facilitates sintering, a process where the catalyst material densifies and forms strong physical and chemical bonds with the cordierite support.

Ensuring Mechanical Longevity

Without high-temperature treatment, the catalyst coating would merely sit on the surface of the honeycomb. The furnace ensures the coating is integral to the structure, preventing it from peeling off during the rapid thermal shocks and vibrations common in industrial exhaust systems.

Batch-to-Batch Consistency

Industrial muffle furnaces are engineered for thermal field stability. This ensures that every part of the honeycomb receives the same thermal energy, resulting in a uniform product where the active components are evenly dispersed across the substrate.

Understanding the Trade-offs

While necessary, the use of high-temperature muffle furnaces involves critical process constraints that must be managed.

Grain Growth vs. Surface Area

There is a delicate balance between bonding strength and surface area. Excessive heat or prolonged exposure can cause "grain growth," where small particles merge into larger ones. This reduces the specific surface area and the number of active sites, potentially lowering catalytic performance.

Atmosphere Limitations

Muffle furnaces typically operate with static air or natural convection, making them ideal for oxidation (calcination). They are generally not suitable for processes requiring strict inert atmospheres (like nitrogen pyrolysis for FeNC catalysts) or active gas flow to remove volatiles rapidly; those processes usually require tube furnaces.

Making the Right Choice for Your Goal

The specific settings and role of your furnace depend heavily on the final requirements of your catalyst.

- If your primary focus is Mechanical Durability: Prioritize higher temperature ranges (900°C–1200°C) to maximize sintering and adhesion to the cordierite substrate, ensuring resistance to thermal shock.

- If your primary focus is High Surface Area: Focus on precise temperature control in the lower calcination range (350°C–550°C) to decompose precursors without triggering excessive grain growth that destroys active sites.

Ultimately, the industrial muffle furnace is the tool that bridges the gap between delicate chemical synthesis and rugged industrial application.

Summary Table:

| Process Phase | Temperature Range | Primary Function/Result |

|---|---|---|

| Decomposition | 350°C - 550°C | Removes metal salts/organic ligands; exposes metal species. |

| Oxidation | 500°C+ | Converts metal atoms into active, robust metal oxide phases. |

| Crystallization | Varies | Defines crystalline structure and catalytic redox activity. |

| Sintering | 900°C - 1200°C | Bonds catalyst to honeycomb substrate; ensures mechanical durability. |

Elevate Your Catalyst Production with KINTEK Precision

Transition from chemical synthesis to rugged industrial performance with KINTEK’s advanced thermal solutions. Backed by expert R&D and manufacturing, KINTEK offers high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems, all fully customizable to meet your unique catalyst preparation needs.

Whether you require precise calcination for high surface area or extreme temperature sintering for mechanical longevity, our lab high-temp furnaces ensure batch-to-batch consistency and superior thermal field stability.

Ready to optimize your material transformation? Contact us today to discuss your project requirements!

Visual Guide

References

- Dalsan Yoo, Jong‐Ki Jeon. Synthesis of Hydroxylammonium Nitrate and Its Decomposition over Metal Oxide/Honeycomb Catalysts. DOI: 10.3390/catal14020116

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What role does a laboratory muffle furnace play in analyzing organic matter degradation? Optimize Biomass Pretreatment

- Why might a muffle furnace have low heating efficiency? Diagnose and Fix Energy Loss Issues

- How does a muffle furnace differ from a pusher furnace? Choose the Right Furnace for Your Lab

- How does a programmable muffle furnace facilitate lithium disilicate crystallization? Master Ceramic Heat Treatments

- What is a box furnace and what are its other names? Discover Its Key Uses and Benefits

- Why is an industrial-grade muffle furnace required for kaolin calcination? Ensure Precise Structural Transformation

- Why is a laboratory high-temperature box furnace essential for komatiite glass? Achieve 1530°C Precision

- What are some critical 'Don'ts' when operating a muffle furnace? Avoid Explosions and Damage