At its core, a box furnace is a type of industrial or laboratory heating equipment defined by its simple, box-like shape and an enclosed heating chamber. It is also commonly known as a muffle furnace or chamber furnace. Its primary function is to provide a highly controlled and uniform thermal environment for heat-treating various materials.

The true value of a box furnace lies not in its shape, but in its ability to deliver precise, repeatable, and uniform heat. This makes it an indispensable tool for altering the physical and chemical properties of materials in a controlled batch process.

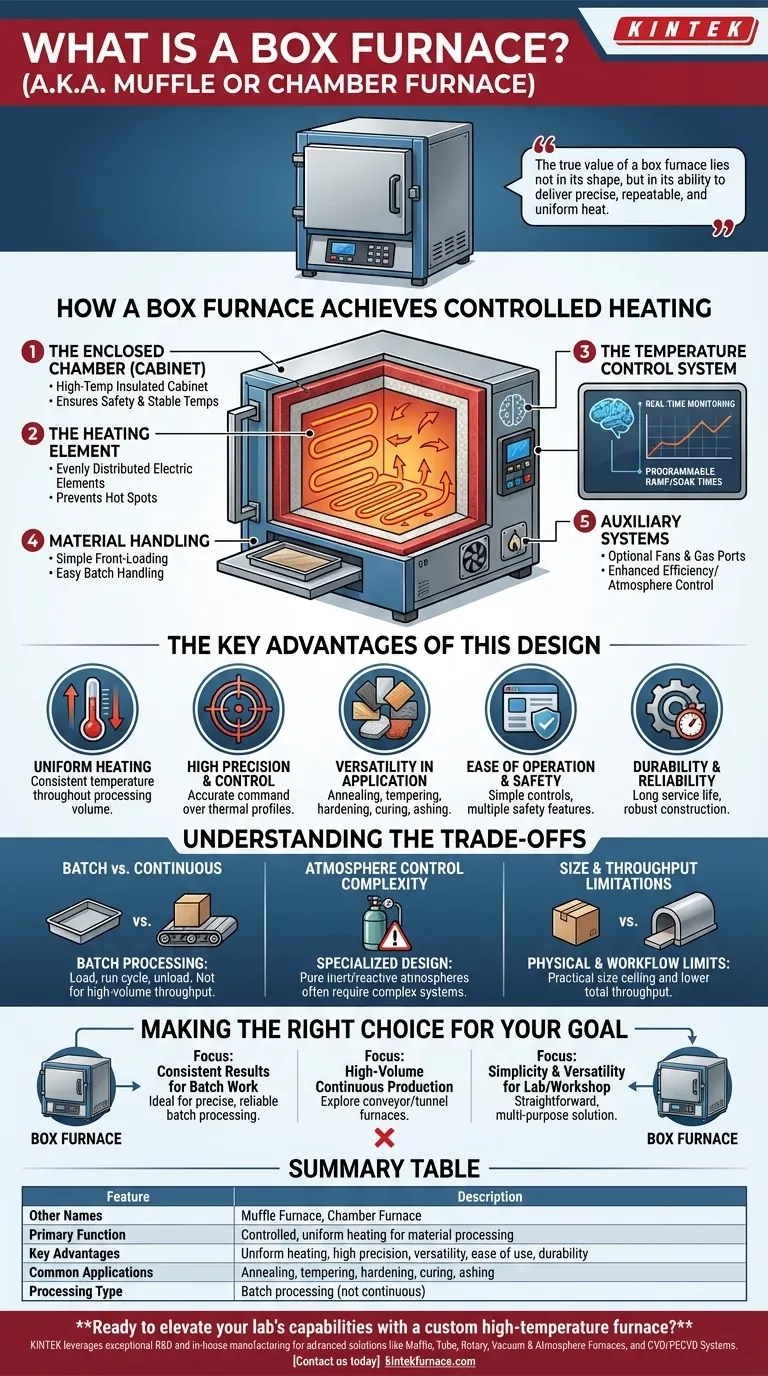

How a Box Furnace Achieves Controlled Heating

A box furnace's effectiveness comes from the synergy of its core components, each designed to manage a specific aspect of the thermal process.

The Enclosed Chamber (Cabinet)

The furnace's cabinet is constructed from high-temperature, heat-resistant materials. This insulated enclosure is critical for maintaining stable internal temperatures and ensuring operator safety.

The Heating Element

Heating is typically achieved using electric heating wires or similar elements. These are strategically placed to distribute energy evenly throughout the chamber, preventing hot spots and ensuring the entire workpiece receives uniform heat.

The Temperature Control System

This is the brain of the furnace. An advanced temperature control system constantly monitors and regulates the internal temperature in real time. This allows for high-precision heating cycles with programmable ramp rates and soak times.

Material Handling

Most box furnaces feature a simple front-loading door for feeding and discharging materials. This design makes it easy and safe to handle individual parts or batches of components.

Auxiliary Systems

Some models include auxiliary equipment like fans for forced convection or ports for introducing specific gases. These features can enhance heating efficiency and allow for more complex atmosphere control.

The Key Advantages of This Design

The simple, enclosed design of a box furnace delivers several distinct operational benefits that make it a staple in many industries and labs.

Uniform Heating

The combination of an insulated chamber and well-placed heating elements ensures that temperature is consistent throughout the processing volume. This uniformity is critical for achieving predictable and repeatable results.

High Precision and Control

Modern temperature controllers give operators precise command over the heat treatment process. This accuracy is essential for sensitive materials and for processes that require strict adherence to thermal profiles.

Versatility in Application

Box furnaces are suitable for an incredibly wide range of materials and thermal processes. Common applications include annealing, tempering, hardening, curing, and ashing.

Ease of Operation and Safety

With simple loading mechanisms and automated temperature and time controls, box furnaces are straightforward to operate. They are also designed with multiple safety features to protect both the operator and the equipment.

Durability and Reliability

These furnaces are typically built for a long service life with minimal maintenance requirements. Their robust construction ensures they can withstand the rigors of repeated high-temperature cycles.

Understanding the Trade-offs

While highly effective, the box furnace design has inherent characteristics that make it suitable for some applications but less ideal for others.

Batch vs. Continuous Processing

A box furnace is fundamentally a batch processing tool. You load a batch, run a cycle, and unload it. It is not designed for the high-volume, continuous throughput that a conveyor or tunnel furnace can provide.

Atmosphere Control Complexity

While many models offer good control over the ambient air environment, achieving and maintaining a specific, highly pure inert or reactive gas atmosphere often requires more specialized and expensive furnace designs.

Size and Throughput Limitations

The "box" design, by its nature, has practical limitations on the size of the parts that can be processed. Its batch-oriented workflow also places a ceiling on total production throughput compared to continuous systems.

Making the Right Choice for Your Goal

Selecting the right furnace depends entirely on the specific demands of your process.

- If your primary focus is consistent results for batch work: The box furnace's uniform heating and precise temperature control make it an ideal and reliable choice.

- If your primary focus is high-volume, continuous production: You should explore other designs like conveyor or tunnel furnaces, as the box furnace is designed for discrete batches.

- If your primary focus is simplicity and versatility for a lab or workshop: A box furnace offers a straightforward, multi-purpose solution for a wide range of common heat treatment tasks.

Understanding these core principles ensures you select a furnace that is not just a tool, but a solution tailored to your specific thermal processing needs.

Summary Table:

| Feature | Description |

|---|---|

| Other Names | Muffle Furnace, Chamber Furnace |

| Primary Function | Controlled, uniform heating for material processing |

| Key Advantages | Uniform heating, high precision, versatility, ease of use, durability |

| Common Applications | Annealing, tempering, hardening, curing, ashing |

| Processing Type | Batch processing (not continuous) |

Ready to elevate your lab's capabilities with a custom high-temperature furnace? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced solutions like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental needs. Contact us today to discuss how we can enhance your thermal processing efficiency and results!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- Why is a high-performance muffle furnace required for the calcination of nanopowders? Achieve Pure Nanocrystals

- What environmental conditions are critical for SiOC ceramicization? Master Precise Oxidation & Thermal Control

- How do you clean a muffle furnace? Ensure Peak Performance and Longevity

- How do you prevent maintenance on a muffle furnace? Extend Lifespan with Proactive Care

- What is the role of a muffle furnace in the synthesis of water-soluble Sr3Al2O6? Precision in SAO Production