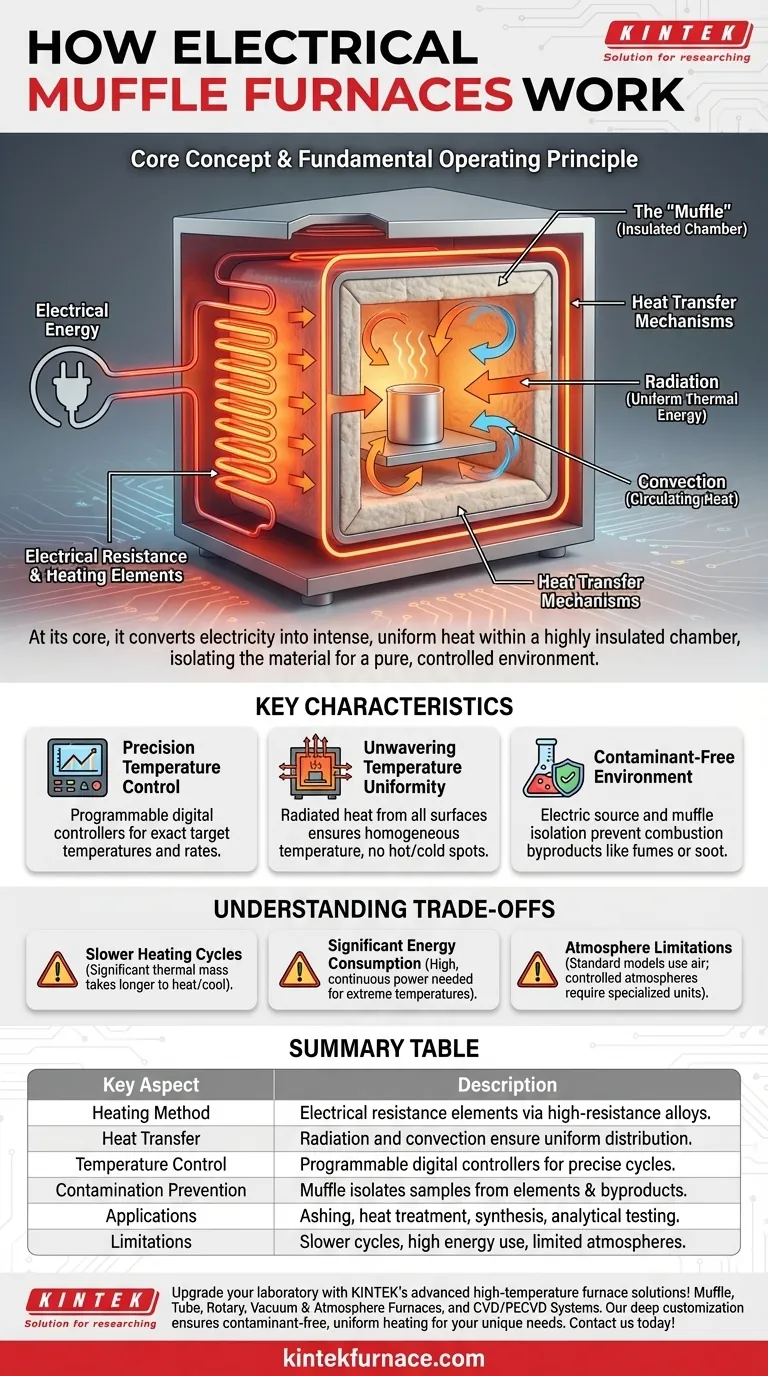

At its core, an electrical muffle furnace works by converting electricity into intense, uniform heat within a highly insulated chamber. It uses high-resistance heating elements, often made of iron-chrome alloys, to generate thermal energy. This heat is then transferred to the workload through radiation and convection, all while the "muffle"—the insulated inner chamber—isolates the material from direct contact with the heating elements, ensuring a pure and controlled environment.

The defining principle of a muffle furnace is not just about achieving high temperatures, but about achieving them with precision and cleanliness. Its design isolates the material being heated, guaranteeing that the process is free from the contaminants and byproducts associated with combustion-based heating.

The Fundamental Operating Principle

To understand how a muffle furnace achieves such precise results, we must look at its three core components: the heat source, the muffle chamber, and the method of heat transfer.

Electrical Resistance and Heating Elements

The process begins with electrical energy. High-amperage current is passed through specialized heating coils. These coils are engineered from materials with high electrical resistance, causing them to glow red-hot and generate immense heat as they resist the flow of electricity.

The Role of the Muffle

The term "muffle" refers to the furnace's inner chamber, which is constructed from advanced, heat-resistant materials like high-purity ceramic fiber. This chamber serves two critical functions:

- Thermal Insulation: It prevents heat from escaping, making the furnace highly energy-efficient and allowing it to reach and maintain extreme temperatures.

- Material Isolation: It creates a barrier between the sample and the raw heating elements, which is the key to preventing contamination.

Heat Transfer Mechanisms

Unlike a direct flame, a muffle furnace uses indirect heating methods to ensure uniformity.

- Radiation: The hot interior walls of the muffle radiate thermal energy evenly onto the object inside, much like how the sun warms the earth. This is a form of blackbody radiation.

- Convection: Air or atmosphere within the sealed chamber heats up, circulates, and transfers heat throughout the space. This combination of radiation and convection ensures a homogeneous temperature with no hot or cold spots.

Key Characteristics of a Modern Muffle Furnace

The unique operating principle of a muffle furnace gives it several key advantages that make it indispensable in laboratory and industrial settings.

Precision Temperature Control

Modern furnaces feature fully programmable digital controllers. Users can set precise target temperatures, define heating and cooling rates, and hold temperatures for specific durations. This level of control is essential for repeatable scientific experiments and delicate material treatments.

Unwavering Temperature Uniformity

Because heat is radiated from all interior surfaces of the chamber, the temperature throughout the processing space is remarkably even. This uniformity is critical when treating workpieces to ensure that the entire object receives the exact same thermal exposure.

Contaminant-Free Environment

Since the heat source is electric, there are no byproducts of combustion like fumes, soot, or gas. The muffle itself further isolates the sample, making these furnaces ideal for sensitive applications like ashing, chemical analysis, and creating high-purity materials where any foreign substance would compromise the results.

Understanding the Trade-offs

While powerful, muffle furnaces have operational characteristics that must be considered. Their design prioritizes stability and cleanliness over raw speed.

Slower Heating Cycles

The same insulation that makes a muffle furnace efficient also gives it significant thermal mass. This means it can take longer to heat up and cool down compared to direct-flame or induction heating methods.

Significant Energy Consumption

Reaching and maintaining very high temperatures (e.g., 1200°C to 1800°C) requires a substantial and continuous supply of electrical power. This is a primary operational cost to factor in for industrial applications.

Atmosphere Limitations

A standard muffle furnace operates with the air present in the chamber. Creating a specific protective atmosphere, such as with inert gases like argon or nitrogen, requires more complex and expensive specialized models with sealed chambers and gas inlets.

Making the Right Choice for Your Application

Selecting and using a muffle furnace effectively depends entirely on your primary objective.

- If your primary focus is precise analytical testing (e.g., ashing or gravimetric analysis): Your priority is the contaminant-free environment and exacting temperature control to ensure pure, repeatable results.

- If your primary focus is material heat treatment (e.g., annealing or tempering metals): The critical features are temperature uniformity and programmable heating/cooling cycles to achieve specific material properties.

- If your primary focus is general high-temperature lab work: You should value the furnace's reliability, safety from open flames, and compact, self-contained design.

Ultimately, a muffle furnace provides an unparalleled level of control, turning a simple box of heat into a precise and repeatable processing tool.

Summary Table:

| Key Aspect | Description |

|---|---|

| Heating Method | Electrical resistance elements generate heat via high-resistance alloys. |

| Heat Transfer | Radiation and convection ensure uniform temperature distribution. |

| Temperature Control | Programmable digital controllers for precise heating/cooling cycles. |

| Contamination Prevention | Muffle chamber isolates samples from heating elements and combustion byproducts. |

| Applications | Ashing, heat treatment, material synthesis, and analytical testing. |

| Limitations | Slower heating cycles, high energy use, and standard models limited to air atmospheres. |

Upgrade your laboratory with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse labs with reliable products like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental needs for contaminant-free, uniform heating. Contact us today to discuss how our furnaces can enhance your precision and efficiency!

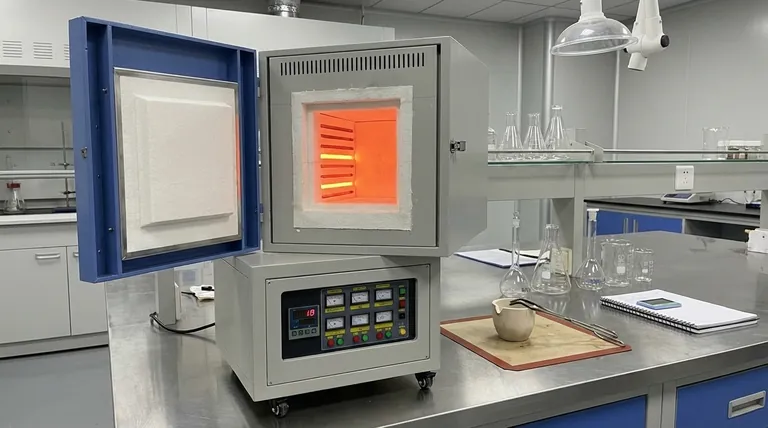

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the core function of a muffle furnace in CuO nanoparticle synthesis? Achieve Precision Calcination

- What is the primary function of a muffle furnace in iron-modified activated carbon prep? Optimize Adsorption Sites

- What is the function of a muffle furnace in SiCf/Al-Mg pretreatment? Optimize Fiber Bonding with Thermal De-sizing

- What key step does a Muffle Furnace perform in the determination of mineral content in Tenebrio molitor larvae?

- Why is re-calcination in a muffle furnace necessary for photocatalysts? Restore Efficiency via Thermal Oxidation