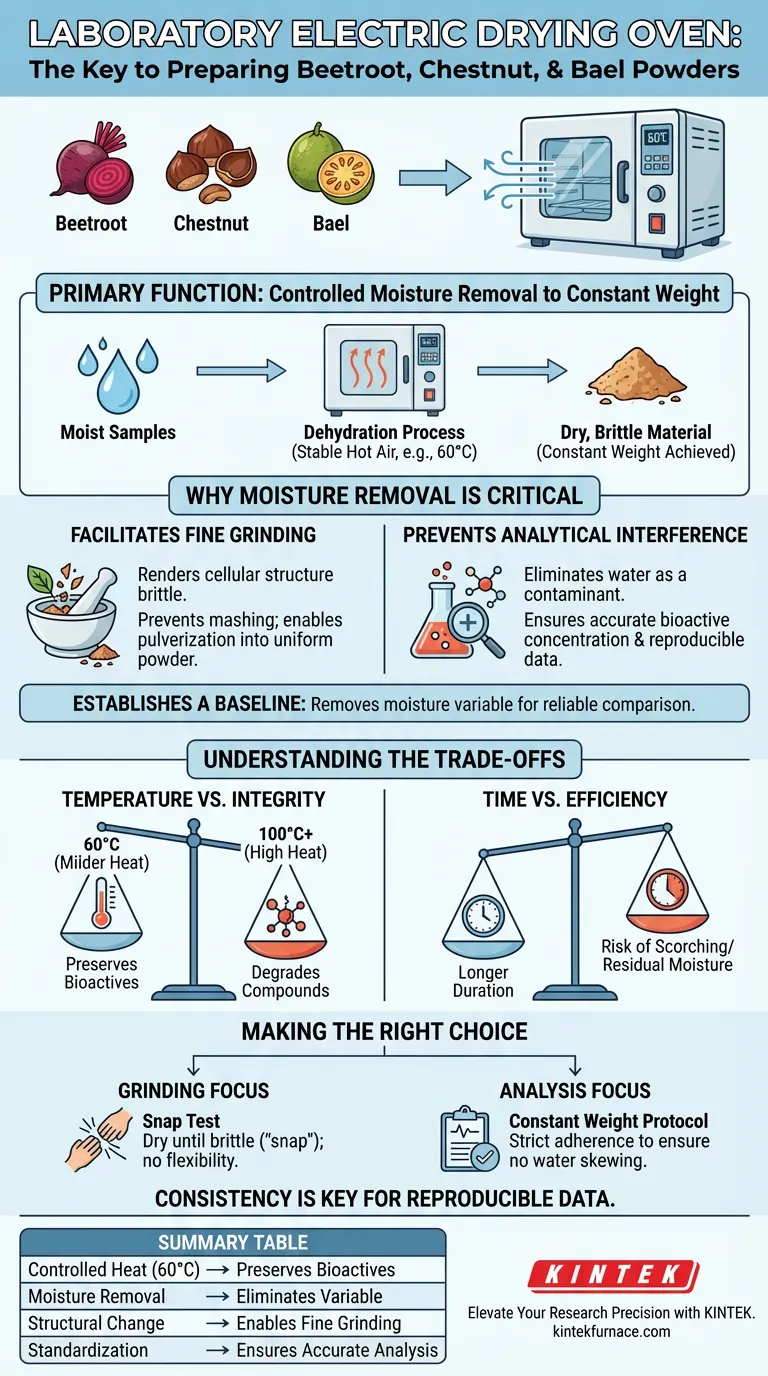

The primary function of a laboratory electric drying oven in this context is to create a controlled thermal environment that removes moisture until the samples reach a constant weight.

For materials like beetroot peel, chestnut peel, and bael pulp, this process uses stable hot air (typically at 60°C) to eliminate water content without destroying sensitive compounds. This dehydration is the foundational step that transforms raw, moist organic matter into a state suitable for fine grinding and accurate bioactive analysis.

Core Takeaway The drying oven acts as a standardization tool, not just a heating device. By removing moisture to a specific endpoint (constant weight), it eliminates water as a variable, ensuring that subsequent chemical analyses are accurate and that the physical material is brittle enough to be pulverized into a uniform powder.

The Mechanics of Sample Preparation

Stable Hot Air Environment

The oven provides a consistent, regulated atmosphere. Unlike open-air drying, which is subject to environmental fluctuations, the electric oven maintains a precise temperature, such as 60°C, throughout the preparation stage.

Achieving Constant Weight

The goal is not simply "dryness" by touch, but a measurable "constant weight." This means the sample is heated until it stops losing mass, indicating that all free moisture has been effectively evaporated.

Why Moisture Removal is Critical

Facilitating Fine Grinding

Raw fruit peels and pulps contain significant water, making them fibrous and pliable. You cannot grind wet material effectively; it will mash rather than pulverize. The drying oven renders the cellular structure brittle, allowing the material to be ground into the fine powder necessary for uniform extraction.

Preventing Analytical Interference

Water is a contaminant in quantitative analysis. If moisture remains in the powder, it dilutes the concentration of target bioactive components and can chemically interfere with downstream reagents. Complete drying ensures that the weight of the powder represents only the solid matter, yielding accurate data.

Establishing a Baseline

Just as fuel samples are dried to prevent endothermic effects during combustion, fruit samples must be dried to establish a reliable baseline. This ensures that any differences found in later analysis are due to the sample's composition, not random variations in initial moisture content.

Understanding the Trade-offs

Temperature vs. Integrity

While supplementary applications (like fuel or coconut husk biochar) use temperatures of 100°C–105°C, fruit peels often require milder heat (around 60°C). High temperatures speed up drying but can degrade the very bioactive compounds you are trying to analyze.

Time vs. Efficiency

Using a lower temperature to preserve sample integrity requires a longer drying duration to reach constant weight. Rushing this process with higher heat risks scorching the sugars in beetroot or bael pulp, while stopping too early leaves residual moisture that ruins the grind.

Making the Right Choice for Your Goal

When preparing organic powders, your drying strategy dictates the quality of your results.

- If your primary focus is Physical Processing (Grinding): Ensure the material is dried until it creates a "snap" when bent; any flexibility indicates residual moisture that will clog grinding equipment.

- If your primary focus is Chemical Analysis (Bioactives): Adhere strictly to the "constant weight" protocol at controlled temperatures (e.g., 60°C) to ensure water does not skew your concentration calculations.

Consistency in the drying stage is the single most important factor in ensuring the reproducibility of your final data.

Summary Table:

| Feature | Function in Sample Preparation | Impact on Quality |

|---|---|---|

| Controlled Heat | Maintains stable 60°C environment | Preserves bioactive compounds/integrity |

| Moisture Removal | Evaporates water to 'constant weight' | Eliminates water as an analytical variable |

| Structural Change | Renders organic matter brittle | Enables fine, uniform grinding without mashing |

| Standardization | Creates a dry solid baseline | Ensures reproducible data for chemical analysis |

Elevate Your Research Precision with KINTEK

Consistency in sample preparation is the foundation of reliable data. Backed by expert R&D and manufacturing, KINTEK offers high-performance laboratory electric drying ovens, Muffle, Tube, Rotary, Vacuum, and CVD systems—all customizable for your unique research needs.

Whether you are processing organic fruit peels or advanced materials, our thermal solutions ensure your samples reach the exact moisture-free state required for perfect pulverization and accurate analysis. Contact us today to discuss how our laboratory high-temp furnaces can streamline your workflow and enhance your analytical accuracy!

Visual Guide

References

- Valorization of fruit byproducts: Proximate analysis, functional characteristics and antioxidant activity of beetroot, chestnut peel and bael pulp. DOI: 10.22271/phyto.2025.v14.i4d.15473

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1200℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Small Rotary Kiln Calciner

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

People Also Ask

- What are the main types of heat treatment furnaces? Choose the Right Furnace for Your Lab or Industry

- Why is a graphite furnace better than a flame in AAS? Unlock Trace-Level Detection for Your Lab

- How does Plasma Flash Sintering (PFS) equipment enable the stabilization of metastable phases? Defy Thermal Limits

- Why is niobium foil wrapped around niobium cavity flanges? Protect Your UHV Seals During Heat Treatment

- Why is a constant temperature drying oven used at 100 °C for HPC preparation? Ensure Optimal Carbonization Results

- What role does an industrial electric furnace play in PAI? Master Thermal Preparation for Metal Matrix Composites

- How do industrial cameras and CNN improve surface defect detection? Revolutionize QC with 95%+ Accuracy

- What is the significance of a laboratory vacuum drying oven in the treatment of hybrid membranes? | Optimize Performance