The primary function of the constant temperature drying oven at 100 °C is the complete removal of moisture from waste coffee grounds. This initial drying step is a non-negotiable prerequisite for mechanical processing. By eliminating moisture, you ensure the raw material can be effectively ground and sieved into a consistent powder, preventing physical clumping and preparing the feedstock for chemical transformation.

Consistently dry feedstock is the baseline for reproducible porous carbon. Removing moisture at 100 °C prevents mechanical agglomeration during grinding and eliminates thermal instability caused by unwanted water evaporation during the subsequent carbonization phase.

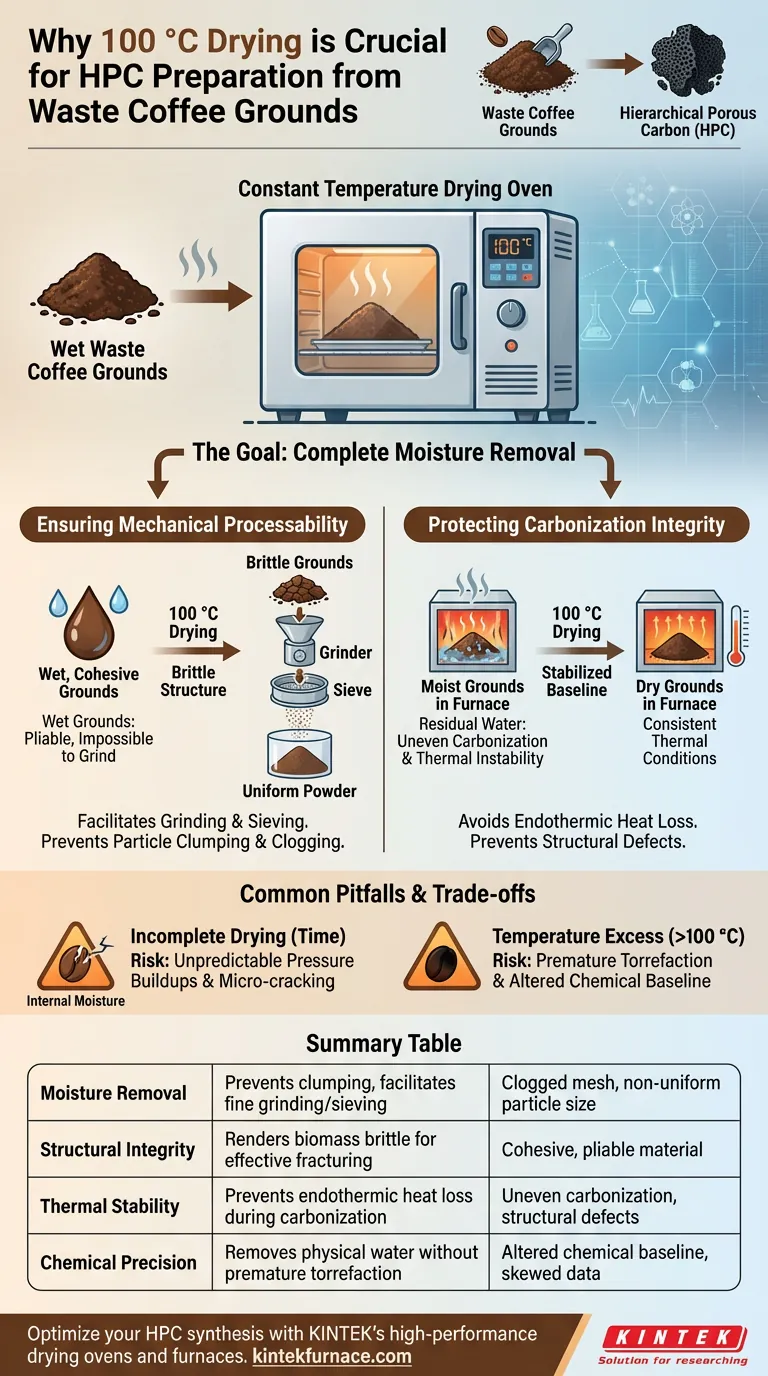

Ensuring Mechanical Processability

The immediate goal of drying at 100 °C is to alter the physical state of the waste coffee grounds to make them suitable for handling.

Facilitating Grinding and Sieving

Raw waste coffee grounds typically contain significant residual moisture. Wet grounds are cohesive and pliable, making them impossible to grind into a fine powder.

Drying renders the cellular structure of the coffee grounds brittle. This brittleness is essential for the mechanical forces of grinding to fracture the material effectively.

Preventing Particle Clumping

Moisture acts as a binding agent between particles. If you attempt to sieve moist grounds, they will agglomerate and clog the mesh.

Using a constant temperature oven ensures the material remains free-flowing. This allows you to achieve a uniform particle size distribution, which is critical for the uniform activation of the carbon later.

Protecting the Carbonization Integrity

Beyond simple handling, moisture removal is chemically necessary for the high-temperature stages of Hierarchical Porous Carbon (HPC) preparation.

Avoiding Uneven Carbonization

The primary reference explicitly notes that residual water leads to uneven carbonization.

If moisture remains within the biomass matrix, the thermal degradation of the material becomes inconsistent. Some areas may dry while others pyrolyze, leading to structural defects in the final carbon framework.

Stabilizing Thermal Conditions

Water evaporation is an endothermic process, meaning it absorbs heat.

If the sample enters the high-temperature furnace wet, the evaporation process will consume thermal energy. This can cause localized temperature fluctuations or lag, destabilizing the combustion environment and compromising the reproducibility of your experimental data.

Common Pitfalls and Trade-offs

While 100 °C is the standard for coffee grounds, understanding the boundaries of this parameter is vital for process control.

The Risk of Incomplete Drying

Setting the duration is just as important as setting the temperature.

If the drying time is insufficient, internal pore moisture may remain even if the surface appears dry. This "hidden" moisture can cause unpredictable pressure buildups or micro-cracking during rapid heating in the tube furnace.

Temperature Precision

100 °C is selected to remove physical water without chemically degrading the biomass.

Significantly exceeding this temperature (e.g., approaching 150-200 °C) risks premature torrefaction. This would alter the chemical composition of the feedstock before the controlled carbonization step begins, skewing your baseline analysis.

Making the Right Choice for Your Goal

To ensure the success of your HPC preparation, apply these principles to your workflow:

- If your primary focus is Physical Consistency: Ensure the material is dried until it reaches a constant weight to guarantee that all clumping risks are eliminated during sieving.

- If your primary focus is Thermal Reproducibility: Treat the drying step as a strict baseline; any variance in moisture content will manifest as noise in your thermal data or carbon yield.

Treat the drying oven not as a storage unit, but as the first active step in chemical synthesis.

Summary Table:

| Drying Requirement | Benefit for HPC Preparation | Impact of Failure |

|---|---|---|

| Moisture Removal | Prevents clumping and facilitates fine grinding/sieving | Clogged mesh and non-uniform particle size |

| Structural Integrity | Renders biomass brittle for effective mechanical fracturing | Cohesive, pliable material impossible to powder |

| Thermal Stability | Prevents endothermic heat loss during carbonization | Uneven carbonization and structural defects |

| Chemical Precision | Removes physical water without premature torrefaction | Altered chemical baseline and skewed data |

Precision starts with the perfect drying environment. Backed by expert R&D and manufacturing, KINTEK offers high-performance drying ovens and specialized high-temp furnaces—including Tube, Vacuum, and CVD systems—designed to meet the rigorous demands of Hierarchical Porous Carbon research. Whether you need standard drying or a fully customizable high-temperature solution for carbonization, our equipment ensures the thermal stability your research requires. Optimize your HPC synthesis with KINTEK—contact us today!

Visual Guide

References

- Arunakumari Nulu, Keun Yong Sohn. N-doped CNTs wrapped sulfur-loaded hierarchical porous carbon cathode for Li–sulfur battery studies. DOI: 10.1039/d3ra08507d

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1200℃ Muffle Oven Furnace for Laboratory

- Molybdenum Disilicide MoSi2 Thermal Heating Elements for Electric Furnace

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Vacuum Dental Porcelain Sintering Furnace for Dental Laboratories

People Also Ask

- What are the main types of furnaces used in foundries for metal casting? Choose the Best for Your Metal

- What is the function of a precise heating system during the hydrolysis of palm kernel oil? Optimize Your Fatty Acid Yield

- How does plasma nitriding equipment improve the performance of titanium alloys in seawater? Boost Marine Durability

- What is the primary function of adding bentonite and cement as binders? Optimize Iron Ore Briquette Strength

- What reaction conditions are provided by stirring and heating equipment? Optimize Non-Aqueous Sol-Gel Synthesis

- What is the purpose of adding aluminum in the vacuum distillation process for magnesium? Enhancing Process Stability and Purity

- What is the significance of the 220 °C annealing process? Unlock High-Purity Anti-Perovskite Thin Film Synthesis

- What is the function of an industrial electric furnace in Al-Cu 224 alloy preparation? Optimize Your Metal Production