The decoking mechanism functions through high-temperature oxidation. By introducing a specific mixture of steam and air into the reactor, the process chemically converts solid carbon deposits on reaction tube walls into gas. This reaction effectively clears physical blockages that accumulate during operation.

The steam and air mixture serves a dual purpose: it removes carbon deposits through gasification and simultaneously regenerates the protective oxide film on alloy surfaces to restore material inertness.

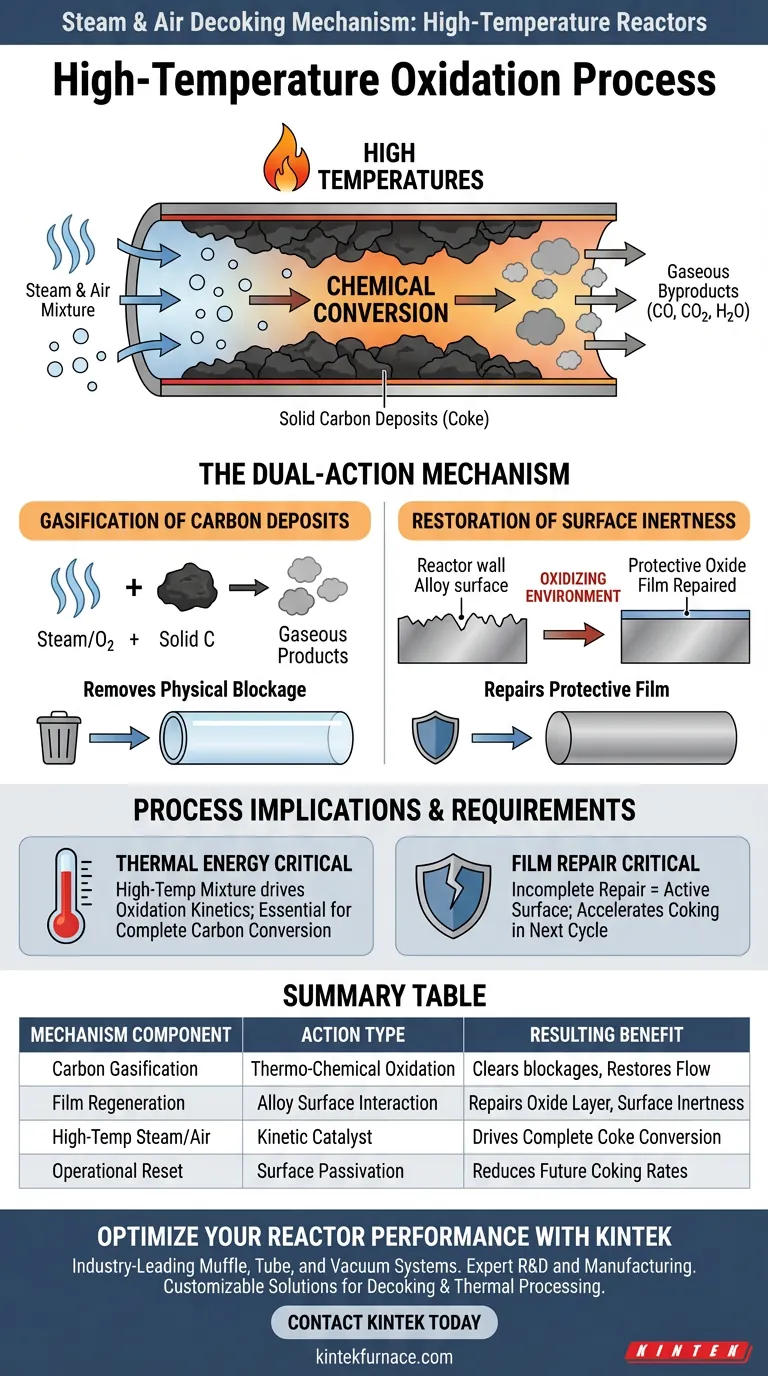

The Dual-Action Mechanism

The effectiveness of steam-air decoking lies in its ability to address both the physical obstruction (the coke) and the chemical state of the reactor material (the alloy).

Gasification of Carbon Deposits

The primary function of the steam and air mixture is to remove physical blockage.

When introduced at high temperatures, the oxygen and steam react with the solid carbon (coke) adhering to the tube walls.

This oxidation reaction transforms the solid carbon into gaseous byproducts, allowing them to be flushed out of the system.

Restoration of Surface Inertness

Removing the coke is only half of the requirement; the reactor walls must also be prepared for the next run.

The process leverages the oxidizing environment to chemically interact with the exposed alloy surfaces.

This interaction repairs the protective film on the metal, restoring the material's surface inertness.

This step is critical, as a restored surface helps mitigate rapid coke formation in the subsequent cracking cycle.

Understanding Process Implications

While this mechanism is vital for reactor maintenance, it relies on strict operational conditions to be effective.

The Requirement for Thermal Energy

This process is not a passive wash; it is a thermal-chemical reaction.

It strictly requires a high-temperature mixture to drive the oxidation kinetics. Without sufficient heat, the conversion of carbon to gas will remain incomplete.

The Criticality of Film Repair

The restoration of the protective film is not merely a byproduct; it is a necessity for longevity.

If the decoking process clears the carbon but fails to fully repair the oxide film, the alloy surface may remain active.

An active surface can lead to accelerated coking rates immediately upon restarting the reactor, reducing the efficiency of the next cycle.

Ensuring Long-Term Reactor Health

To maximize the benefits of the steam-air decoking process, align your operational focus with the specific needs of your reactor's lifecycle.

- If your primary focus is Flow Restoration: Ensure the temperature of the steam-air mixture is sufficiently high to drive the complete gasification of all physical carbon deposits.

- If your primary focus is Asset Longevity: Prioritize the duration and quality of the oxidizing phase to guarantee the protective alloy film is fully regenerated before returning to production.

Effective decoking is not just about cleaning tubes; it is about resetting the chemical integrity of your reactor surfaces.

Summary Table:

| Mechanism Component | Action Type | Resulting Benefit |

|---|---|---|

| Carbon Gasification | Thermo-Chemical Oxidation | Clears physical blockages & restores flow |

| Film Regeneration | Alloy Surface Interaction | Repairs protective oxide layer & surface inertness |

| High-Temp Steam/Air | Kinetic Catalyst | Drives complete conversion of solid coke to gas |

| Operational Reset | Surface Passivation | Reduces coking rates in subsequent cycles |

Optimize Your Reactor Performance with KINTEK

Don't let carbon buildup compromise your laboratory efficiency. KINTEK provides industry-leading Muffle, Tube, and Vacuum systems backed by expert R&D and manufacturing. Our high-temperature furnaces are fully customizable to meet your unique decoking and thermal processing needs, ensuring both asset longevity and material inertness.

Ready to enhance your thermal processing capabilities? Contact KINTEK today to consult with our experts on the perfect high-temp solution for your lab.

Visual Guide

References

- Hamed Mohamadzadeh Shirazi, Kevin M. Van Geem. Effect of Reactor Alloy Composition on Coke Formation during Butane and Ethane Steam Cracking. DOI: 10.1021/acs.iecr.3c03180

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- Why is a secondary calcination furnace required after ball milling? Unlock High-Purity Hydroxyapatite Synthesis

- Why is a nitrogen (N2) purging system necessary for biomass torrefaction? Prevent Combustion and Maximize Biochar Yield

- What is the function of zone melting purification equipment in the preparation of CsPbBr3 perovskite single crystals? Key for 6N.

- How does a dual-stage salt bath design address steel wire sorbitization? Master Precision Gradient Cooling

- Why use nitrogen and flow meters in sludge pyrolysis? Ensuring Superior Biochar Quality and Anaerobic Integrity

- Why is a laboratory vacuum oven required for GO slurry? Preserving Chemical Integrity in Graphene Oxide Dehydration

- How does a gas mass flow control system (MFC) prevent copper foil adhesion? Mastering Atmospheric Purity

- What is the operating principle of a vacuum freeze-dryer in the fabrication of carbon aerogels? Master Sublimation