The fluidized bed reactor (FBR) is the superior choice for co-gasification primarily because its fluid-like mixing environment masters the complexity of mixing biomass with non-biomass waste. By suspending fuel particles in a turbulent gas stream, it guarantees the rigorous physical contact and thermal stability necessary to process fuels that vary significantly in size, density, and composition.

Co-gasification requires processing fuels with vastly different physical properties. The fluidized bed reactor solves this through intense mixing and precise temperature regulation, ensuring uniform reactions despite the heterogeneity of the feedstock.

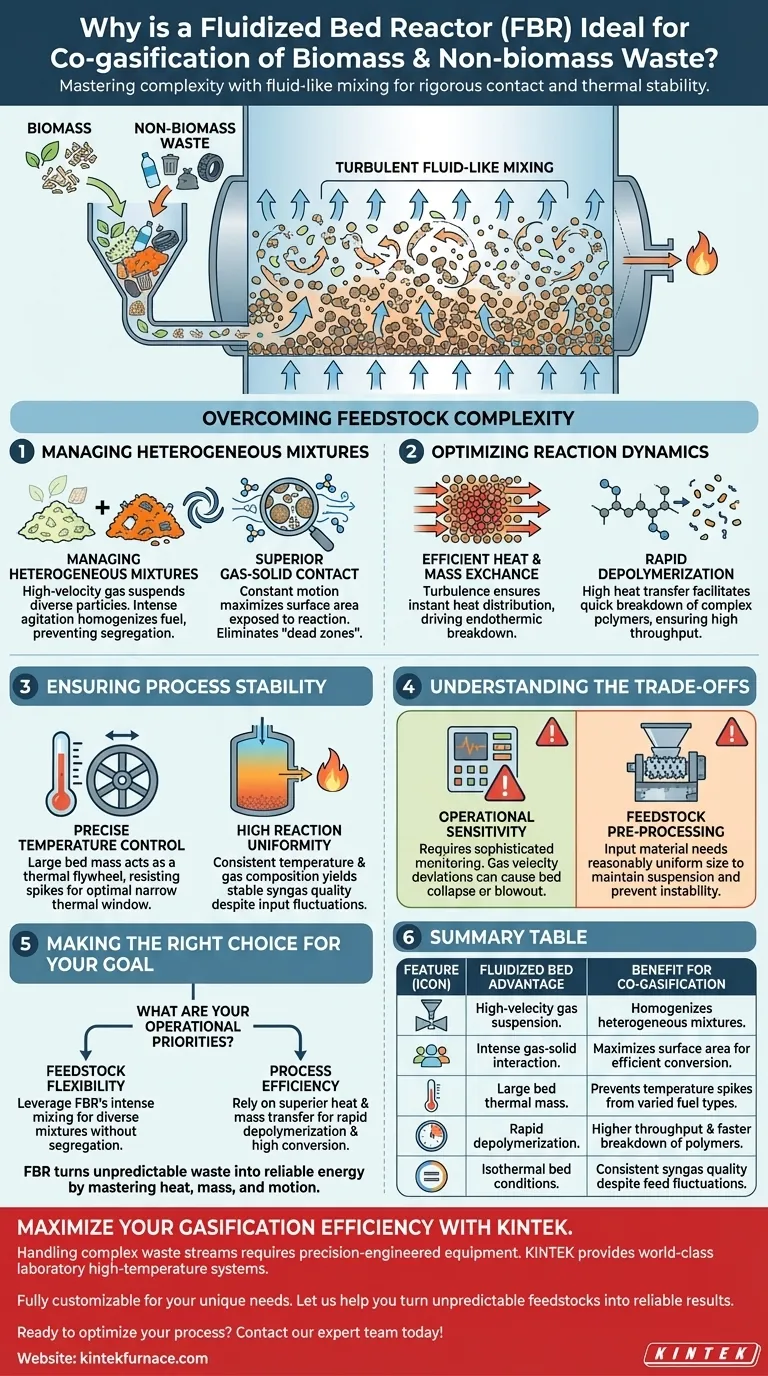

Overcoming Feedstock Complexity

Managing Heterogeneous Mixtures

Biomass and non-biomass waste rarely share the same physical characteristics. One might be dense and dry, while the other is light and moist.

Fluidized bed reactors utilize high-velocity gas to suspend these solid particles, creating a turbulent mixture. This intense agitation homogenizes the fuel within the reactor, preventing segregation and ensuring that even the most diverse waste mixtures are treated as a consistent input.

Superior Gas-Solid Contact

For gasification to occur efficiently, the solid fuel must interact intimately with the gasifying agent (such as air or steam).

The FBR design ensures excellent gas-solid contact by keeping particles in constant motion. This maximizes the surface area exposed to the reaction, eliminating "dead zones" where untreated waste could accumulate.

Optimizing Reaction Dynamics

Efficient Heat and Mass Exchange

The turbulence within a fluidized bed does more than just mix; it acts as a powerful vehicle for energy transfer.

Efficient heat and mass exchange is a hallmark of this technology. The rapid movement of particles ensures that heat is distributed instantly throughout the bed, driving the endothermic reactions required to break down complex waste materials.

Rapid Depolymerization

Complex waste mixtures often contain long-chain polymers that are difficult to break down.

The high heat transfer rates in an FBR facilitate rapid depolymerization. The molecular structure of the waste is shattered quickly and effectively, preventing the formation of unwanted byproducts and ensuring high throughput.

Ensuring Process Stability

Precise Temperature Control

Co-gasification can be volatile, as different waste components release energy at different rates.

FBRs offer precise temperature control because the large mass of the bed acts as a thermal flywheel. It resists sudden temperature spikes or drops, maintaining the narrow thermal window required for optimal gasification.

High Reaction Uniformity

In static or fixed-bed reactors, temperature gradients can lead to inconsistent gas quality.

The FBR delivers high reaction uniformity across the entire vessel. Because the temperature and gas composition are consistent throughout the bed, the resulting syngas quality remains stable, even when the input waste stream fluctuates slightly.

Understanding the Trade-offs

Operational Sensitivity

While the FBR excels at control, it demands it in return. Achieving the precise temperature control mentioned requires sophisticated monitoring systems. Deviations in gas velocity can lead to a loss of fluidization (bed collapse) or excessive carryover of particles (blowout).

Feedstock Pre-processing

Although the reactor handles heterogeneous feedstocks better than alternatives, there are limits. To maintain the suspension necessary for excellent gas-solid contact, the input material must still be processed to a reasonably uniform size range to prevent aerodynamic instability within the bed.

Making the Right Choice for Your Goal

Whether you choose a fluidized bed reactor depends on your specific operational priorities.

- If your primary focus is feedstock flexibility: Leverage the FBR’s intense mixing capabilities to process diverse mixtures of biomass and waste without segregation.

- If your primary focus is process efficiency: Rely on the reactor’s superior heat and mass transfer rates to ensure rapid depolymerization and high conversion speeds.

By mastering the variables of heat, mass, and motion, the fluidized bed reactor turns unpredictable waste streams into a reliable energy resource.

Summary Table:

| Feature | Fluidized Bed Advantage | Benefit for Co-gasification |

|---|---|---|

| Mixing Dynamics | High-velocity gas suspension | Homogenizes heterogeneous biomass/waste mixtures |

| Contact Efficiency | Intense gas-solid interaction | Maximizes surface area for efficient conversion |

| Thermal Control | Large bed thermal mass | Prevents temperature spikes from varied fuel types |

| Reaction Speed | Rapid depolymerization | Higher throughput and faster breakdown of polymers |

| Uniformity | Isothermal bed conditions | Consistent syngas quality despite feed fluctuations |

Maximize Your Gasification Efficiency with KINTEK

Handling complex waste streams requires precision-engineered equipment. KINTEK provides world-class laboratory high-temperature systems, including Muffle, Tube, Rotary, Vacuum, and CVD systems, specifically designed to meet the rigorous demands of material research and energy conversion.

Backed by expert R&D and manufacturing, our systems are fully customizable to your unique co-gasification or thermal processing needs. Let us help you turn unpredictable feedstocks into reliable results.

Ready to optimize your process? Contact our expert team today!

Visual Guide

References

- Mariana Busto, Carlos R. Vera. Catalytic and Non-Catalytic Co-Gasification of Biomass and Plastic Wastes for Energy Production. DOI: 10.3390/catal15090844

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant Rotating Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

People Also Ask

- Why is a vacuum drying oven used for BC-FeOOH biochar? Protect Reactivity and Prevent Particle Aggregation

- What role does an industrial box-type resistance furnace play in phosphor conversion? Powering Material Synthesis

- Why is a laboratory electric blast drying oven necessary for determining the water absorption rate of mortar?

- What is the temperature of a graphite furnace? Unlock Extreme Heat Up to 3000°C

- Why is a blank control experiment without a sample required? Ensure Accuracy in Oxide Scale Measurement

- Why is an equivalent diffusion combustion heat source term integrated into the furnace temperature field simulation?

- Why is precise superheat temperature control required? Unlock High-Quality Soft Magnetic Nanocrystalline Alloys

- What is the use of high temperature furnace? Transform Materials with Precision Thermal Processing