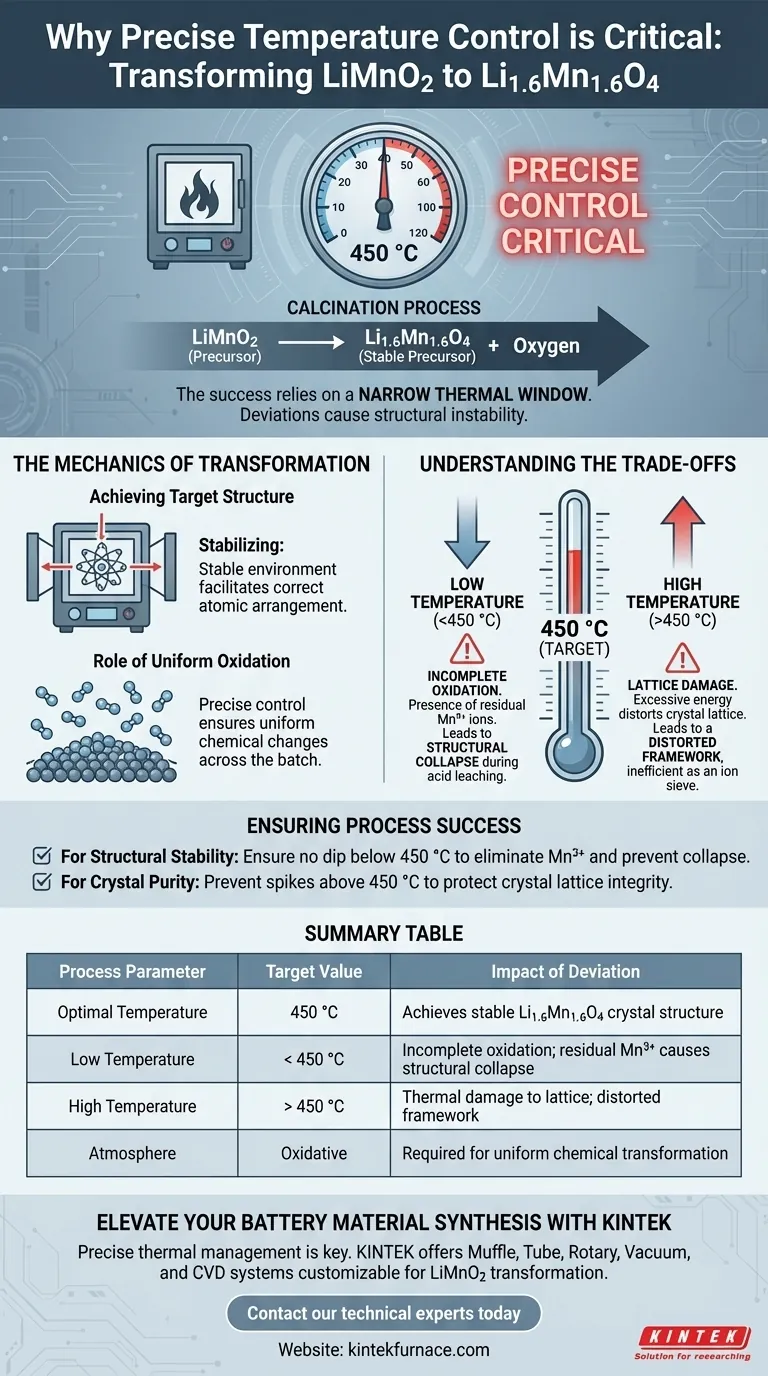

Precise temperature control at exactly 450 °C is the defining factor in successfully converting LiMnO2 into a stable lithium-ion sieve precursor. This thermal precision ensures the complete oxidation required to form the target Li1.6Mn1.6O4 crystal structure while preventing defects that would cause the material to fail during later processing stages.

The success of this transformation relies entirely on maintaining a narrow thermal window. Deviations result in either incomplete oxidation or lattice damage, rendering the final product structurally unstable for subsequent acid leaching.

The Mechanics of the Transformation

Achieving the Target Structure

The primary goal of the calcination process is to transform LiMnO2 into Li1.6Mn1.6O4.

This specific stoichiometry is not achieved through random heating; it requires a stable environment to facilitate the correct atomic arrangement. The furnace acts as the stabilizer, ensuring the material reaches the precise state required for high-performance applications.

The Role of Uniform Oxidation

During oxidative calcination, oxygen must interact uniformly with the precursor material.

Fluctuations in temperature can create uneven reaction rates across the batch. Precise control guarantees that the entire batch undergoes the same chemical changes simultaneously, leading to a consistent and repeatable product.

Understanding the Trade-offs: The Thermal Window

Deviating from the target temperature of 450 °C results in two distinct failure modes. Understanding these risks is essential for optimizing furnace parameters.

The Risk of Undershooting (Low Temperature)

If the furnace temperature drops below the optimal range, oxidation will be incomplete.

The immediate chemical consequence is the presence of residual Mn3+ ions. While this might seem minor, it is catastrophic for the next stage of production.

When the material undergoes acid leaching, these residual ions cause the structural collapse of the material. The precursor effectively crumbles at the molecular level, ruining the lithium-ion sieve.

The Risk of Overshooting (High Temperature)

Exceeding the 450 °C target is equally detrimental, though the mechanism of failure differs.

Excessive heat imparts too much energy into the system, leading to damage of the target crystal lattice. Instead of a stable structure, you obtain a distorted framework that cannot perform efficiently as an ion sieve.

Ensuring Process Success

If your primary goal is Structural Stability:

- Ensure the furnace does not dip below 450 °C to eliminate residual Mn3+ ions and prevent collapse during acid leaching.

If your primary goal is Crystal Purity:

- Prevent temperature spikes above 450 °C to protect the integrity of the crystal lattice from thermal damage.

By strictly maintaining this thermal balance, you ensure the generation of a uniform, high-performance precursor capable of withstanding downstream processing.

Summary Table:

| Process Parameter | Target Value | Impact of Deviation |

|---|---|---|

| Optimal Temperature | 450 °C | Achieves stable Li1.6Mn1.6O4 crystal structure |

| Low Temperature | < 450 °C | Incomplete oxidation; residual Mn3+ causes structural collapse |

| High Temperature | > 450 °C | Thermal damage to the crystal lattice; distorted framework |

| Atmosphere | Oxidative | Required for uniform chemical transformation |

Elevate Your Battery Material Synthesis with KINTEK

Precise thermal management is the difference between a high-performance lithium-ion sieve and structural failure. At KINTEK, we understand that maintaining a strict 450 °C environment requires superior equipment.

Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, and CVD systems—all customizable to meet the exacting thermal profiles required for LiMnO2 transformation. Our high-temperature lab furnaces provide the uniformity and stability needed to prevent lattice damage and ensure complete oxidation.

Ready to optimize your calcination process? Contact our technical experts today to find the perfect furnace solution for your unique research and production needs.

Visual Guide

References

- Jing Zhu, Run-Min Yao. Synthesis of Porous Lithium Ion Sieve with High Purity for Li+ Adsorption. DOI: 10.3390/ma18102373

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- How can high-temperature furnace systems be used to evaluate and prevent slagging? Optimize Boiler Performance

- What is the purpose of secondary heating at 200 degrees Celsius for Ge-S-Cd alloys? Ensure Stress-Free Samples

- Why is precise control of heating and cooling rates necessary for iron-doped ceria? Optimize Your Catalyst Performance

- What are the objectives of melt stirring and insulation treatment during the Al-5Er-Ti master alloy preparation process?

- Why must g-C3N4 thin films be metal-coated before SEM? Achieve High-Resolution Imaging with Vacuum Deposition

- What are the core process advantages of using a microwave reactor? Maximize Speed & Efficiency in Lab Characterization

- What is the purpose of using a thermal evaporation coating system? Enhancing I-V Testing Accuracy for Nanocomposites

- What are the disadvantages of batch furnaces? Key Limitations in Efficiency and Quality