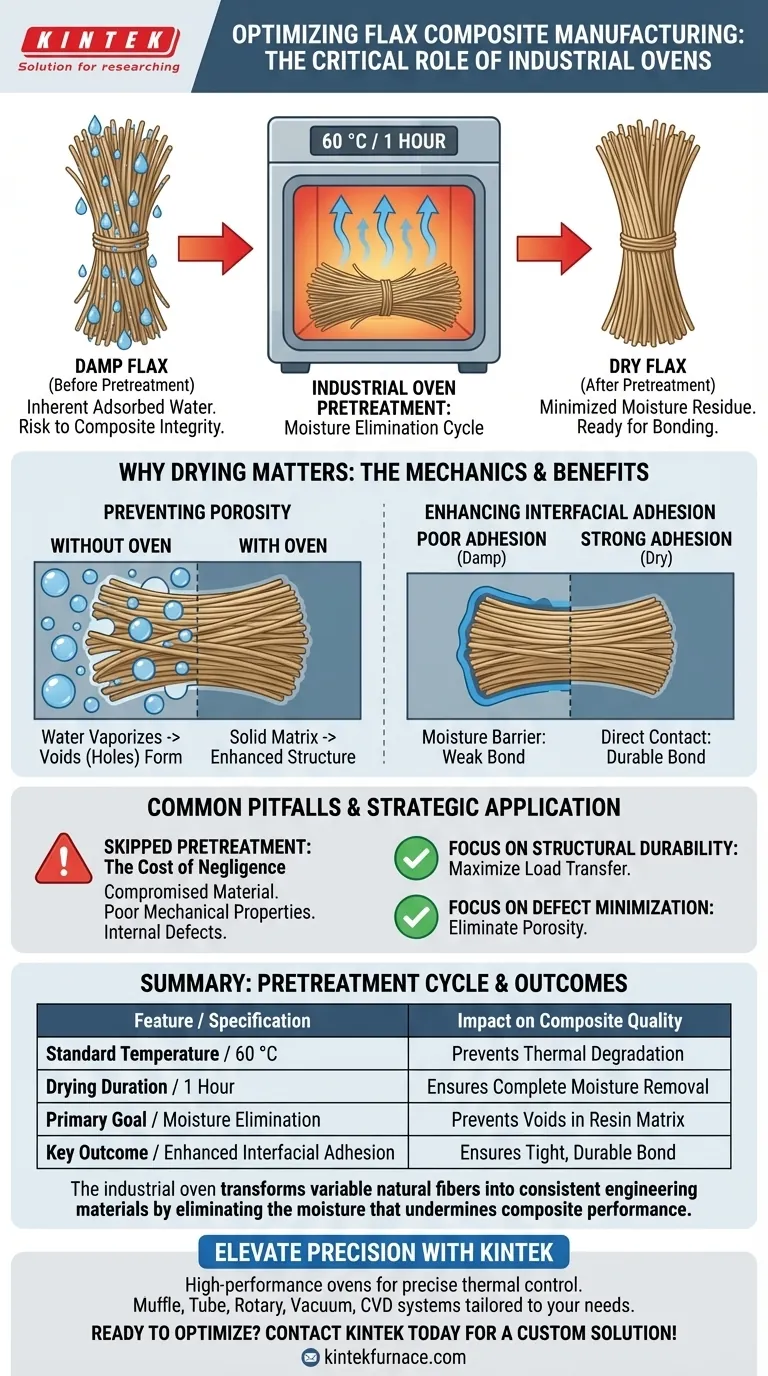

The primary function of an industrial oven in the pretreatment of natural flax fibers is to eliminate moisture content prior to composite processing. This critical drying step, typically executed at 60 °C for one hour, removes adsorbed water from the fibers to ensure the structural integrity of the final material.

Core Takeaway Natural fibers are inherently prone to holding moisture, which is detrimental to composite manufacturing. The industrial oven acts as a necessary safeguard, preventing trapped water from creating structural voids and ensuring the resin bonds securely to the fiber.

The Mechanics of Moisture Removal

To understand the necessity of this equipment, you must look at the physical properties of natural flax. Unlike synthetic fibers, natural fibers actively adsorb water from their environment.

Removing Adsorbed Water

The industrial oven targets adsorbed water—moisture that has adhered to the surface or permeated the structure of the flax.

If this water remains during the manufacturing stage, it becomes a contaminant. The oven ensures that moisture residue is minimized before the fiber ever touches the resin.

The Standard Pretreatment Cycle

According to standard manufacturing protocols, the effective baseline for this process is 60 °C for one hour.

This specific duration and temperature balance the need to thoroughly dry the material without thermally degrading the natural fibers themselves.

Why Dry Fibers Matter for Structural Integrity

The deep need for an industrial oven is not just about "drying"; it is about preventing catastrophic failure modes within the composite material.

Preventing Porosity

The most immediate risk of processing damp fibers is the formation of pores within the resin matrix.

If water is present during the curing process, it often vaporizes or occupies space that should be filled by the resin. This results in voids (holes) inside the material, which significantly weaken the composite.

Enhancing Interfacial Adhesion

For a composite to be strong, the load must transfer effectively from the resin (the matrix) to the fiber (the reinforcement).

Moisture creates a barrier that prevents the resin from wetting the fiber surface. By drying the flax, the oven enhances interfacial adhesion, ensuring a tight, durable bond between the fiber and the resin.

Common Pitfalls to Avoid

While the process seems straightforward, understanding the risks of negligence is vital.

The Cost of Skipped Pretreatment

Attempting to bypass the drying phase to save production time is a fundamental error.

Without the oven treatment, moisture residue is all but guaranteed to compromise the material. The trade-off for saving one hour of oven time is often a finished product with poor mechanical properties and internal defects.

Making the Right Choice for Your Goal

Using an industrial oven for flax pretreatment is a quality control necessity. Here is how to apply this to your manufacturing process:

- If your primary focus is Structural Durability: Adhere strictly to the drying cycle to maximize interfacial adhesion and load transfer capabilities.

- If your primary focus is Defect Minimization: Use the oven to eliminate moisture residue, which is the leading cause of porosity and void formation in the resin matrix.

The industrial oven transforms variable natural fibers into consistent engineering materials by eliminating the moisture that undermines composite performance.

Summary Table:

| Feature | Pretreatment Specification | Impact on Composite Quality |

|---|---|---|

| Standard Temperature | 60 °C | Prevents thermal degradation of natural fibers |

| Drying Duration | 1 Hour | Ensures complete removal of adsorbed water |

| Primary Goal | Moisture Elimination | Prevents voids and pores in the resin matrix |

| Key Outcome | Enhanced Interfacial Adhesion | Ensures a tight, durable bond between fiber and resin |

Elevate Your Composite Manufacturing Precision with KINTEK

Don't let moisture compromise the structural integrity of your natural fiber composites. KINTEK provides high-performance industrial ovens and lab high-temp furnaces designed to deliver the precise thermal control needed for critical pretreatment cycles.

Backed by expert R&D and manufacturing, we offer customizable Muffle, Tube, Rotary, Vacuum, and CVD systems tailored to your unique research or production needs. Ensure consistent material quality and eliminate defects by partnering with the experts in thermal processing.

Ready to optimize your drying process? Contact KINTEK today for a custom solution!

Visual Guide

References

- Veena Phunpeng, Wipada Boransan. Recycled PET Sandwich Cores, Waste-Derived Carbon Additive, and Cure-Rate Control: FTIR/SEM Study of Flexural Performance in Flax Fiber-Reinforced Composites. DOI: 10.3390/fib13100142

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1200℃ Muffle Oven Furnace for Laboratory

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Dental Porcelain Sintering Furnace for Dental Laboratories

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

People Also Ask

- What is the core role of a high-pressure autoclave in the synthesis of LTA zeolites? Achieve Precise Crystal Growth

- What role does a belt-type rapid sintering furnace play in forming metal contacts? Optimize Solar Cell Efficiency

- What are the advantages of a high-pressure nitrogen environment? Speed and Efficiency in Wood Thermal Modification

- How do lab furnaces simulate fire environments for UHPFRC testing? Achieving ISO834 Standard Compliance

- How is the influence of permeation temperature on steel hardness quantified? Precision Modeling for Plasma Nitriding

- What is the purpose of vacuum sputtering systems for haptic device electrodes? Achieve High-Precision Metal Deposition

- Why is a laboratory tablet press used to briquette powder before vacuum carbothermic reduction? Ensure Efficient & Stable Magnesium Production

- What is the technical purpose of the ball milling process for Ti12%Zr? Master Mechanical Activation & Alloying