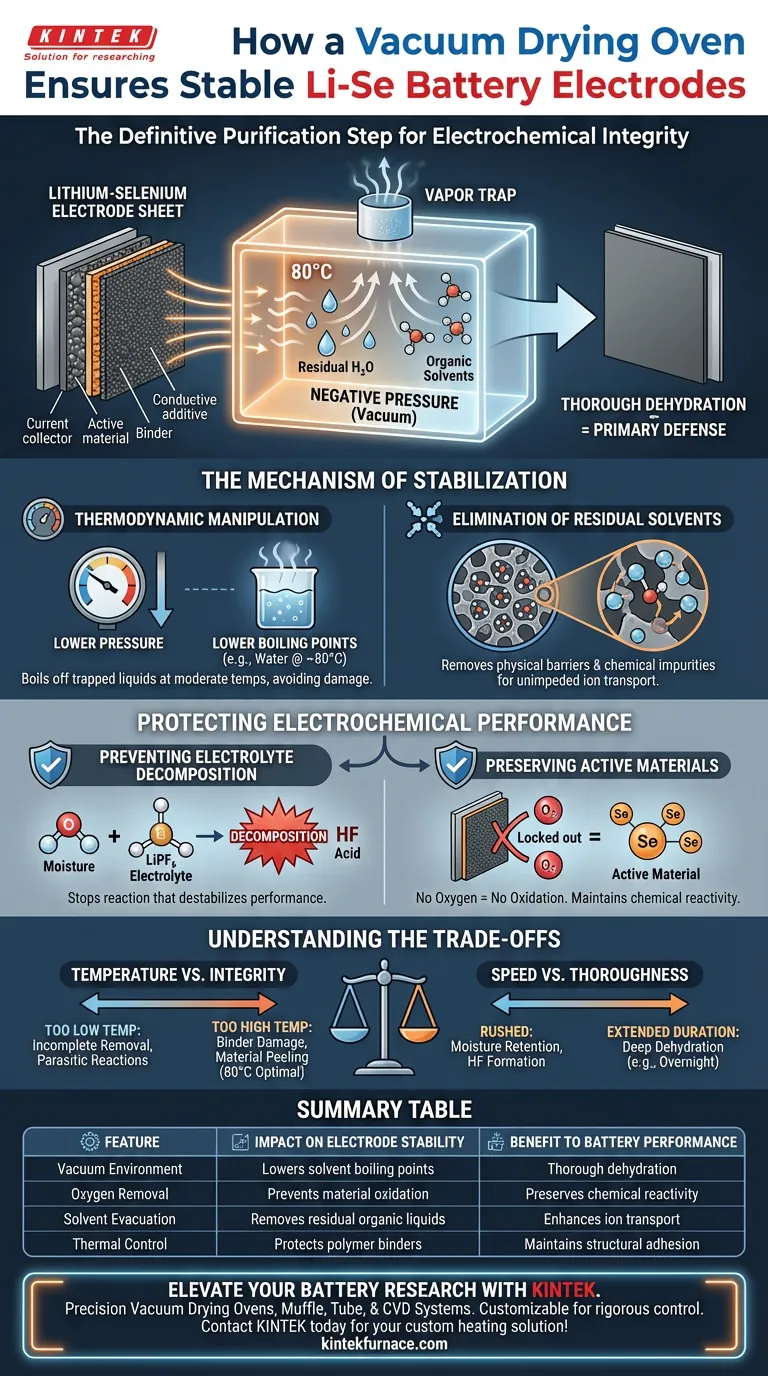

Vacuum drying is the definitive purification step that bridges the gap between electrode coating and cell assembly. By maintaining a constant 80°C environment under negative pressure, the oven lowers the boiling points of residual organic solvents and moisture, forcing them to evaporate from the electrode sheets. This thorough dehydration is the primary defense against moisture contamination, which is the leading cause of electrolyte decomposition and subsequent battery failure.

Core Takeaway The stability of a lithium-selenium battery relies on the absolute purity of its internal environment. A vacuum drying oven ensures this by eliminating microscopic traces of liquid that would otherwise react with the electrolyte, preserving the electrochemical integrity of the cell.

The Mechanism of Stabilization

To understand how stability is achieved, we must look beyond simple drying. The process involves precise control over thermodynamics and chemical preservation.

Thermodynamic Manipulation

The vacuum oven does not rely on heat alone. By creating a vacuum, the equipment significantly lowers the atmospheric pressure surrounding the electrode sheets.

This pressure drop reduces the boiling points of trapped liquids, specifically moisture and organic solvents.

Consequently, these liquids can be boiled off at a moderate 80°C, ensuring complete removal without subjecting the sensitive electrode materials to destructive high temperatures.

Elimination of Residual Solvents

During the coating process, electrodes are often treated with solvents.

The vacuum drying process ensures these solvents are thoroughly evacuated from the porous structure of the electrode.

Failure to remove these residues creates physical barriers and chemical impurities that impede ion transport.

Protecting Electrochemical Performance

The primary value of the vacuum drying process lies in what it prevents. The stability of the lithium-selenium battery is directly linked to the absence of contaminants.

Preventing Electrolyte Decomposition

The most critical function of the oven is protecting the battery's electrolyte.

If residual moisture remains in the electrode, it reacts chemically with the electrolyte once the battery is assembled.

This reaction leads to electrolyte decomposition, which fundamentally destabilizes the battery's electrochemical performance and ruins test results.

Preserving Active Materials

Vacuum drying offers a protective atmosphere for the electrode materials themselves.

Because the drying occurs in a vacuum, oxygen is evacuated from the chamber.

This prevents oxygen-sensitive active materials from oxidizing during the heating process, maintaining their chemical reactivity and surface functional groups.

Understanding the Trade-offs

While vacuum drying is essential, it requires a delicate balance of parameters to be effective.

Temperature vs. Integrity

The primary reference cites 80°C as effective, but this is a specific operating point.

If the temperature is too low, solvent removal may be incomplete, leading to "parasitic reactions" inside the finished cell.

Conversely, excessive heat can damage the polymer binders that hold the electrode together, causing the active material to peel away from the current collector.

Speed vs. Thoroughness

Vacuum drying is rarely a fast process; it often requires extended duration (e.g., overnight) to ensure deep dehydration.

Rushing this step to increase manufacturing throughput invariably leads to trace moisture retention.

Even microscopic amounts of water can trigger the formation of hydrofluoric acid (HF) within the cell, which aggressively corrodes internal components.

Making the Right Choice for Your Goal

To maximize the stability of your lithium-selenium electrodes, tailor your drying protocol to your specific priorities.

- If your primary focus is Electrolyte Stability: Ensure the vacuum level is maximized to lower the boiling point of water as much as possible, preventing hydrolysis reactions later.

- If your primary focus is Material Longevity: Strictly adhere to the 80°C limit to dry the electrode without thermally stressing the binder or oxidizing the active selenium material.

- If your primary focus is Structural Adhesion: Monitor the drying rate; rapid boiling of solvents can disrupt the coating, so apply vacuum gradually to maintain a uniform electrode surface.

True electrode stability is not achieved during assembly, but during the meticulous removal of impurities in the vacuum oven.

Summary Table:

| Feature | Impact on Electrode Stability | Benefit to Battery Performance |

|---|---|---|

| Vacuum Environment | Lowers solvent boiling points | Thorough dehydration at safe temperatures |

| Oxygen Removal | Prevents material oxidation | Preserves chemical reactivity of active materials |

| Solvent Evacuation | Removes residual organic liquids | Enhances ion transport and prevents impurities |

| Thermal Control | Protects polymer binders | Maintains structural adhesion and surface integrity |

Elevate Your Battery Research with KINTEK

Precision in electrode preparation is the difference between a high-performing cell and electrochemical failure. Backed by expert R&D and manufacturing, KINTEK offers specialized Vacuum Drying Ovens, Muffle, Tube, and CVD systems—all customizable for your unique lab requirements.

Our equipment ensures the rigorous temperature and pressure control needed to eliminate moisture and preserve active materials without compromise. Don't let trace contaminants ruin your results.

Contact KINTEK today to find your custom heating solution!

Visual Guide

References

- Ying Wang, Yun Wang. <i>In‐situ</i> confining selenium within bubble – like carbon nanoshells for ultra‐stable Li−Se batteries. DOI: 10.1002/chem.202304114

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- 1200℃ Muffle Oven Furnace for Laboratory

- Vacuum Induction Melting Furnace

People Also Ask

- What is the function of a ball mill in the raw material pretreatment stage for the szaibelyite vacuum thermal reduction process?

- What is the effect of 750°C to 950°C on activated carbon? Optimize Pore Structure & Surface Area

- What is the function of a furnace in CuAlMn alloy treatment? Achieve Perfect Microstructural Homogenization

- What is the purpose of performing a 1200°C solution treatment for high-entropy alloys? Achieve Total Homogenization

- How does a Rapid Thermal Processing (RTP) system function? Optimize Nanowire Device Performance Today

- What are the core advantages of using a microwave sintering furnace? Unlock Precision in Al2O3/TiC Ceramics

- Why is titanium used as a gettering agent in TiCo1-xCrxSb preparation? Achieve Purity in Your Alloy Synthesis

- Why is a heating furnace set to 155 °C for sulfur melt-diffusion? Unlock Optimal Battery Material Synthesis