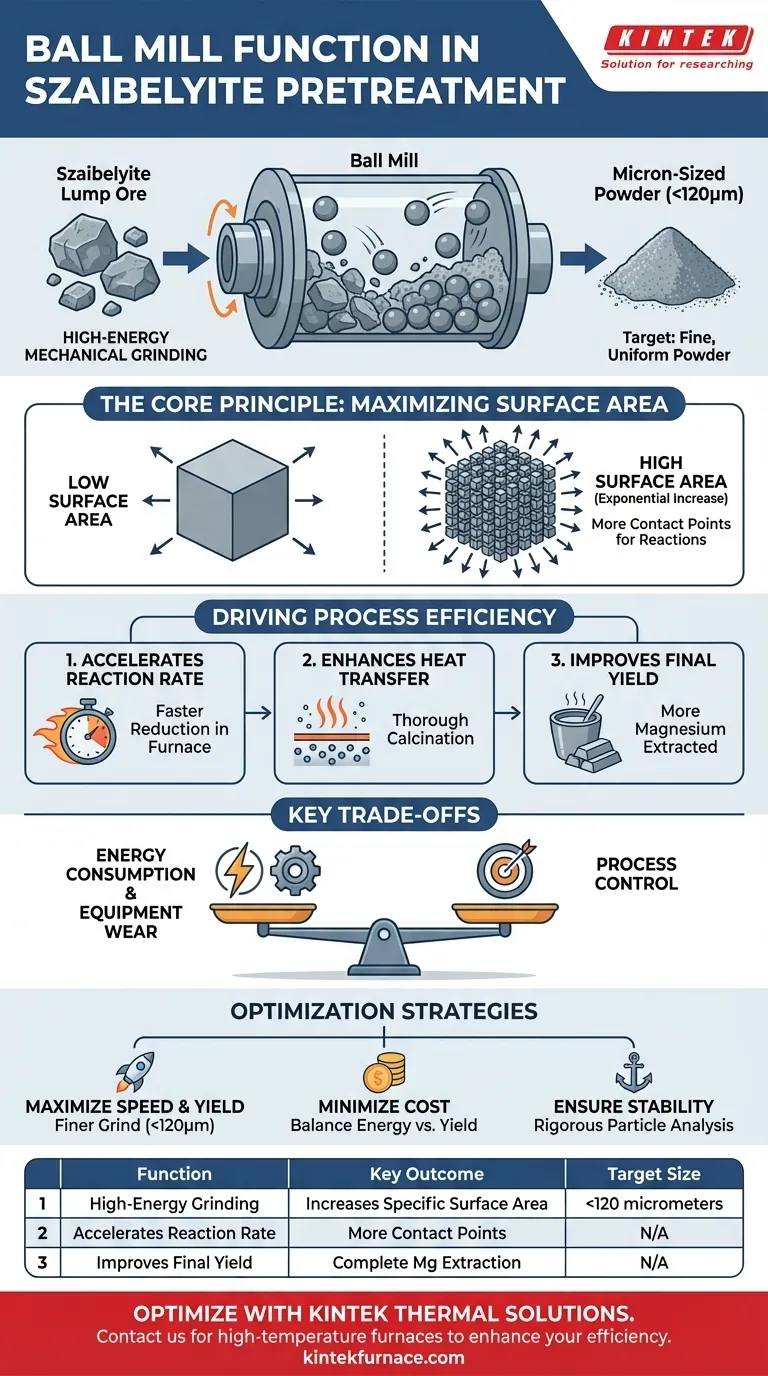

In the pretreatment of szaibelyite ore, the primary function of a ball mill is to perform high-energy mechanical grinding. This process pulverizes large, irregular lumps of ore into a fine, uniform powder with a particle size typically less than 120 micrometers, fundamentally preparing it for the subsequent chemical reactions.

The core purpose of using a ball mill is not simply to crush rock, but to strategically increase the material's specific surface area. This physical change is the single most important factor in accelerating reaction rates and maximizing the final yield of magnesium in the vacuum thermal reduction process.

The Core Principle: Maximizing Surface Area for Reaction Efficiency

The physical state of a raw material dictates how efficiently it can react chemically. For solid-state reactions like those in magnesium production, the available surface for chemical contact is the primary limiting factor.

From Lump Ore to Micron-Sized Powder

A ball mill is a powerful rotating cylinder containing steel balls. As the cylinder turns, the balls cascade and tumble, creating intense impact and attrition forces that crush the szaibelyite ore into a fine, consistent powder.

This transformation is purely mechanical but has profound chemical implications. It changes the material from a low-surface-area solid into a high-surface-area powder.

Why Particle Size Matters

The target of less than 120 micrometers is not arbitrary. This level of fineness creates an exponential increase in the total surface area of the material compared to its original lump form.

Imagine a single, solid cube. It has six faces available for a reaction. If you crush that cube into a thousand tiny cubes, you expose thousands of new faces. This is the fundamental principle at work.

How Increased Surface Area Drives the Process Forward

By creating a fine powder, the ball mill directly enhances the performance of every subsequent step in the production chain, from heating to the final chemical reduction.

Enhancing Subsequent Reactions

With significantly more surface area exposed, the particles can make more thorough contact with each other and with the process environment. This improves heat transfer during calcination and ensures intimate contact between reactants during the reduction phase.

Accelerating the Reduction Rate

The vacuum thermal reduction reaction can only occur where the reactant particles physically touch. A larger surface area creates millions more contact points, dramatically increasing the number of simultaneous reactions.

This leads to a significantly faster overall reaction rate, reducing the time required in the high-temperature furnace.

Improving Final Magnesium Yield

A faster and more complete reaction directly translates to a higher final reduction rate. This means more of the magnesium locked within the szaibelyite ore is successfully extracted, improving the overall efficiency and output of the entire process.

Understanding the Key Trade-offs

While essential, the ball milling stage is not without its own operational considerations. Optimizing this step requires balancing competing factors.

Energy Consumption

High-energy grinding is an energy-intensive process. Grinding to a finer particle size requires more time and electrical power, representing a significant operational cost.

Process Control

Achieving a consistent particle size distribution is critical. Too coarse, and the reaction is slow and inefficient. Too fine, and it can lead to handling issues like dust or particle agglomeration, while offering diminishing returns on reaction speed for the energy invested.

Equipment Wear

The intense impact and abrasion inside a ball mill cause wear on the steel grinding media and the mill's internal lining. This necessitates regular maintenance and replacement, which factors into the overall cost of production.

Making the Right Choice for Your Goal

The optimization of the ball milling stage depends entirely on your primary process objective.

- If your primary focus is maximizing reaction speed and yield: Achieving a consistent particle size well below the 120-micrometer threshold is the most direct path to improving furnace throughput.

- If your primary focus is minimizing operational costs: You must carefully balance the energy cost of finer grinding against the value of the increased magnesium yield to identify the most economically efficient particle size.

- If your primary focus is process stability: Implementing rigorous particle size analysis is crucial to ensure the feedstock entering the furnace is consistent batch after batch, leading to predictable and reliable outcomes.

Ultimately, mastering this mechanical pretreatment step is foundational to achieving chemical and operational excellence in magnesium production.

Summary Table:

| Function | Key Outcome | Target Particle Size |

|---|---|---|

| High-Energy Grinding | Increases specific surface area | < 120 micrometers |

| Accelerates Reaction Rate | Creates more contact points for reactions | N/A |

| Improves Final Yield | Enables more complete magnesium extraction | N/A |

Optimize your szaibelyite pretreatment process with KINTEK's robust thermal solutions. The efficiency of your ball milling stage is directly linked to the performance of your furnace. Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, and CVD systems, all customizable for unique needs. Ensure your finely ground ore achieves maximum reduction yield with a furnace built for precision and reliability. Contact us today to discuss how our high-temperature furnaces can enhance your magnesium production efficiency.

Visual Guide

Related Products

- Ultra Vacuum Electrode Feedthrough Connector Flange Power Lead for High Precision Applications

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What is the primary function of the vacuum pump system in the magnesium powder evaporation process? Ensure High Purity & Efficiency

- What is the function of vacuum systems and sealing connectors? Mastering Pure and Controlled Chemical Environments

- What are the main technical requirements for vacuum pumps in vacuum sintering furnaces? Ensure Material Purity and Efficiency

- How does a high-vacuum pump system facilitate the synthesis of high-quality calcium-based perrhenates? Expert Synthesis

- Why is a high vacuum system critical for sealing the quartz tube used in Fe3GeTe2 single crystal preparation?