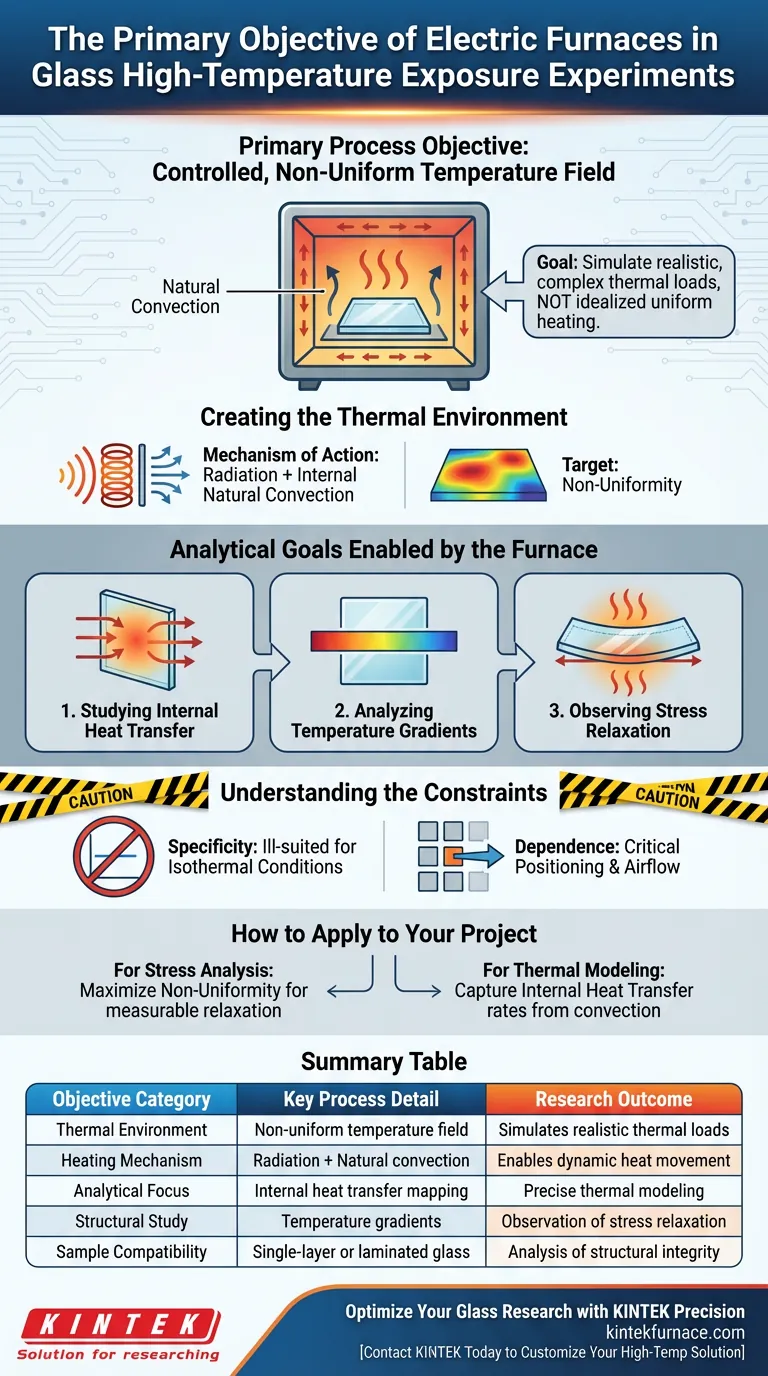

The primary process objective of using an electric furnace in these experiments is to simulate a controlled high-temperature environment that exposes glass samples to a specific, non-uniform temperature field. By utilizing electric heating elements and facilitating internal natural convection, the furnace creates the distinct thermal conditions necessary to test single-layer or laminated glass.

While generating heat is the function, the specific objective is to create a controlled, non-uniform temperature distribution. This environment is essential for isolating and analyzing internal heat transfer, temperature gradients, and stress relaxation within the glass.

Creating the Thermal Environment

The Mechanism of Action

The electric furnace operates by generating heat radiation directly from its heating elements.

Simultaneously, it facilitates internal natural convection within the chamber. This dual approach ensures the glass is exposed to a dynamic thermal load rather than static conduction.

Target: Non-Uniformity

Unlike processes that require perfectly even heating, the objective here is to provide a non-uniform temperature field.

This specific distribution is applied to the glass samples (whether single-layer or laminated) to mimic realistic, complex exposure scenarios rather than idealized conditions.

Analytical Goals Enabled by the Furnace

Studying Internal Heat Transfer

The controlled environment allows researchers to map how heat moves through the glass structure.

By manipulating the furnace output, you can observe the rate and direction of internal heat transfer under varying high-temperature conditions.

Analyzing Temperature Gradients

The non-uniform field creates distinct temperature gradients across the sample's surface and thickness.

These gradients are critical data points, as uniform heating often fails to reveal how glass responds to localized thermal variances.

Observing Stress Relaxation

The ultimate physical phenomenon being studied is stress relaxation.

The furnace provides the precise thermal context needed to observe how the glass structure mechanically relaxes or deforms in response to the induced temperature gradients.

Understanding the Constraints

Specificity of Application

This setup is engineered specifically for studying gradients and stress in a non-uniform field.

It is likely ill-suited for experiments requiring isothermal (perfectly uniform) conditions, as the natural convection and radiation serve to create variation rather than eliminate it.

Dependence on Convection

The process relies heavily on internal natural convection.

This means the positioning of the sample relative to the heating elements and airflow is a critical variable that must remain consistent to ensure reproducible data.

How to Apply This to Your Project

When designing your high-temperature exposure experiment, align your furnace settings with your specific analytical goals:

- If your primary focus is Stress Analysis: Ensure the furnace is calibrated to maximize the non-uniformity of the temperature field to induce measurable stress relaxation.

- If your primary focus is Thermal Modeling: Focus on capturing data regarding the internal heat transfer rates driven by the natural convection within the chamber.

Use the electric furnace not just to heat the glass, but to create the precise thermal imbalances that reveal its structural limits.

Summary Table:

| Objective Category | Key Process Detail | Research Outcome |

|---|---|---|

| Thermal Environment | Non-uniform temperature field | Simulates realistic thermal loads |

| Heating Mechanism | Radiation + Natural convection | Enables dynamic heat movement |

| Analytical Focus | Internal heat transfer mapping | Precise thermal modeling |

| Structural Study | Temperature gradients | Observation of stress relaxation |

| Sample Compatibility | Single-layer or laminated glass | Analysis of structural integrity |

Optimize Your Glass Research with KINTEK Precision

Are you looking to master complex thermal gradients in your materials research? KINTEK provides industry-leading Muffle, Tube, Rotary, Vacuum, and CVD systems designed for the most demanding high-temperature applications. Whether you are analyzing stress relaxation or internal heat transfer, our customizable laboratory furnaces offer the stability and control necessary for reproducible scientific data.

Backed by expert R&D and world-class manufacturing, KINTEK empowers researchers to push the limits of glass and ceramic science.

Contact KINTEK Today to Customize Your High-Temp Solution

Visual Guide

References

- Maximilian Möckel, Michael Engelmann. Temperature distribution and stress relaxation in glass under high temperature exposition. DOI: 10.1007/s40940-025-00296-1

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- What is the role of a ventilated oven in the drying pretreatment of uranium tailings? Ensure Safety and Flowability

- Why is multiple remelting necessary for Bi-Sb alloys? Achieve Perfect Compositional Uniformity Today

- What role does a forced air drying oven play in the preparation of zinc oxide nanoparticles? Prevent Agglomeration

- How does Vacuum Degassing (VD) influence spinel inclusions in heavy rail steel? Controlling Refractory Erosion

- Why is a precision temperature control system essential for wood carbonization? Achieve Perfect Shape Fidelity

- Why is a laboratory drying oven used for cottonseed oil extraction? Achieve Maximum Yield and Accuracy

- How does a plasma surface metallurgy furnace achieve infiltration? Engineer High-Performance Diffusion Bonds

- What are the advantages of a laboratory vacuum drying oven for CT and CCT precursors? Preserve Nanostructural Integrity