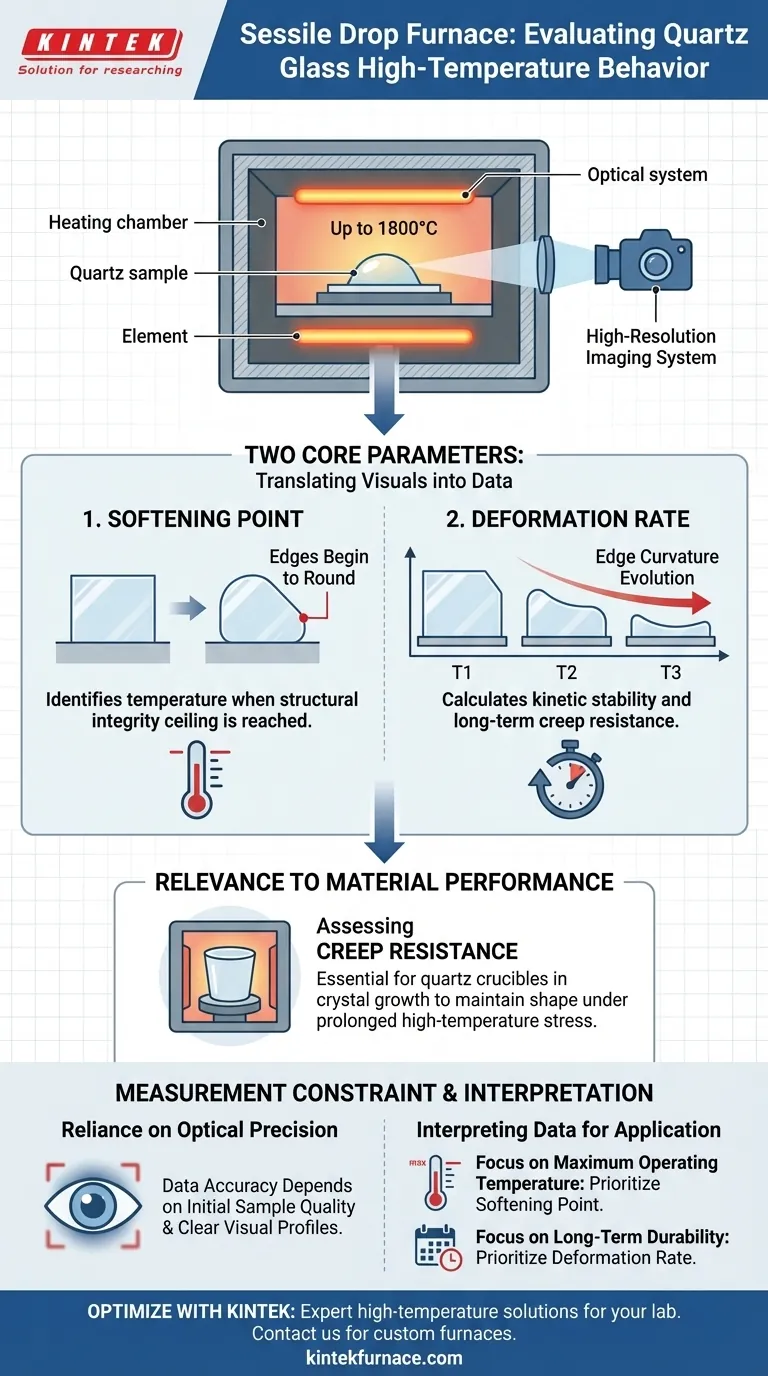

A sessile drop furnace primarily delivers critical dynamic thermomechanical data by utilizing high-resolution imaging to monitor quartz samples at temperatures up to 1800 degrees Celsius. Specifically, it provides two core parameters: the softening point, identified when sample edges begin to round, and the deformation rate, which is calculated based on the curvature of those edges.

By translating visual morphological changes into quantifiable data, the sessile drop furnace serves as the definitive tool for evaluating the high-temperature creep resistance of quartz crucibles used in crystal growth.

Analyzing Morphological Changes in Real-Time

To understand the behavior of quartz glass under extreme heat, this equipment moves beyond simple temperature readings. It focuses on physical, geometric changes captured through an optical system.

Determining the Softening Point

The softening point is a critical thermal threshold. The furnace identifies this specific temperature by detecting the exact moment the sample's edges lose their sharpness.

When the sample edges begin to round, the system records the temperature. This data point establishes the upper limit of the material's structural integrity before it transitions into a more viscous state.

Calculating the Deformation Rate

Beyond the initial softening, understanding how the material continues to move is vital. The system monitors the progression of the sample's shape over time.

This is determined specifically by analyzing edge curvature. By tracking how the curvature evolves, the system calculates a rate of deformation, providing a kinetic view of the material's stability.

The Relevance to Material Performance

The raw data provided by the furnace is not just about melting; it is about mechanical endurance under thermal stress.

Assessing Creep Resistance

The combination of the softening point and deformation rate is used to evaluate creep resistance.

Creep defines how a solid material moves slowly or deforms permanently under mechanical stresses. For quartz crucibles used in crystal growth, high creep resistance is essential to maintain shape and safety during prolonged high-temperature processes.

Understanding the Measurement Constraints

While this method provides precise morphological data, it is important to recognize the nature of the measurement.

Reliance on Optical Precision

Because the system relies on a high-resolution imaging system, the data is derived entirely from visual profiles.

This means the accuracy of the "softening point" and "deformation rate" depends heavily on the initial quality of the sample. If the sample edges are not clearly defined or if the line of sight is obstructed, the determination of edge rounding and curvature may be compromised.

Interpreting the Data for Application

When reviewing the output from a sessile drop furnace, align the parameters with your specific engineering requirements.

- If your primary focus is Maximum Operating Temperature: Prioritize the softening point to establish the absolute thermal ceiling before structural geometry is compromised.

- If your primary focus is Long-Term Durability: Prioritize the deformation rate, as this indicates how the quartz crucible will withstand prolonged stress (creep) during extended crystal growth cycles.

By isolating these two parameters, you can predict how quartz components will physically hold up in the most demanding thermal environments.

Summary Table:

| Core Parameter | Measurement Indicator | Engineering Significance |

|---|---|---|

| Softening Point | Rounding of sample edges | Defines maximum structural integrity temperature |

| Deformation Rate | Evolution of edge curvature | Indicates long-term creep resistance and durability |

| Visual Profile | High-resolution optical imaging | Translates morphology into quantifiable kinetic data |

Optimize Your Material Performance with KINTEK

Ensure the structural integrity of your quartz components under extreme conditions. Backed by expert R&D and manufacturing, KINTEK offers a comprehensive range of high-temperature solutions, including Muffle, Tube, Rotary, Vacuum, and CVD systems. Whether you need to determine precise softening points or evaluate long-term creep resistance, our equipment is fully customizable to meet your unique laboratory and industrial requirements.

Ready to elevate your thermal analysis? Contact KINTEK today to discuss your custom furnace needs with our engineering experts.

Visual Guide

References

- Bartłomiej Adam Gaweł, Marisa Di Sabatino. Influence of aluminium doping on high purity quartz glass properties. DOI: 10.1039/d4ra01716a

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ Muffle Oven Furnace for Laboratory

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- Why are carbon nanotubes considered superior adsorbents? Efficient Removal of Harmful Organic Gases

- What are the main types of laboratory furnaces based on size? Find the Perfect Fit for Your Lab's Scale

- What is the function of a high-temperature heating reactor in OPF delignification? Unlock High-Purity Cellulose

- What are the functions of hydrogen gas for graphene on silver? Enhance Crystallinity & Stability

- Why must g-C3N4 thin films be metal-coated before SEM? Achieve High-Resolution Imaging with Vacuum Deposition

- What advantages does a salt bath furnace offer for bainitic transformation? Achieve Superior Steel Microstructures

- Why must ball milling of aluminum alloy powders be in argon? Ensure Material Integrity & Prevent Oxidation

- How does high-temperature calcination affect kaolin? Boost Surface Area and Catalytic Reactivity via Thermal Processing