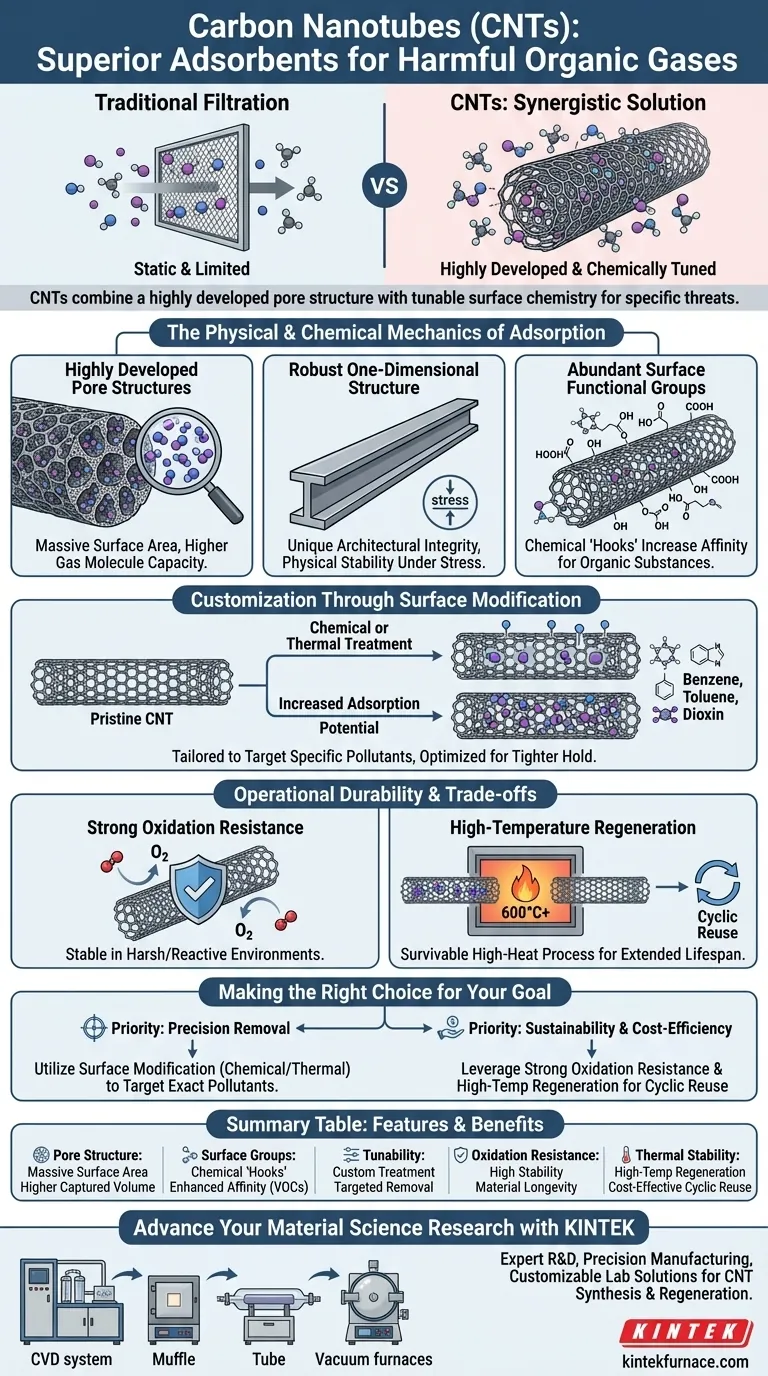

Carbon nanotubes (CNTs) differ from traditional filtration materials because they combine a highly developed pore structure with the ability to be chemically tuned for specific threats. Their superiority lies in their capacity for surface modification to target organic toxins like benzene and dioxin, coupled with an inherent durability that allows them to be regenerated and reused repeatedly under high temperatures.

The core advantage of CNTs is the synergy between physical structure and chemical adaptability. Unlike static filters, CNTs can be engineered to trap specific molecules and possess the oxidation resistance necessary for high-heat regeneration, making them a sustainable solution for long-term industrial cycles.

The Physical and Chemical Mechanics of Adsorption

To understand why CNTs excel, one must look beyond simple filtration and examine how the material interacts with gas molecules on a microscopic level.

Highly Developed Pore Structures

The primary driver of adsorption efficiency is surface area. CNTs possess highly developed pore structures that provide a massive surface area relative to their volume.

This allows a significantly higher quantity of gas molecules to adhere to the material compared to conventional adsorbents.

Robust One-Dimensional Structure

CNTs are defined by a robust one-dimensional structure.

This unique architectural integrity supports the physical stability of the material, ensuring it maintains its porous properties even under stress.

Abundant Surface Functional Groups

Beyond physical pores, the chemical landscape of a CNT is rich with abundant surface functional groups.

These groups act as chemical "hooks," increasing the material's affinity for capturing organic substances.

Customization Through Surface Modification

A defining characteristic of superior adsorbents is the ability to tailor them to a specific problem. CNTs offer exceptional versatility in this regard.

Targeting Specific Pollutants

Through chemical or thermal treatment processes, the surface of CNTs can be modified to selectively target specific harmful organic gases.

This customization is particularly effective for removing volatile organic compounds (VOCs) such as benzene, toluene, and dioxin.

Enhancing Adsorption Potential

These surface modifications do more than just select targets; they actively increase the adsorption potential of the nanotubes.

By altering the surface chemistry, engineers can optimize the CNTs to hold onto these dangerous molecules more tightly than unmodified materials could.

Operational Durability and Trade-offs

While the adsorption capacity is critical, the economic and operational viability of an adsorbent depends on its lifecycle.

Strong Oxidation Resistance

CNTs exhibit strong oxidation resistance, a property that is vital for industrial applications involving harsh environments or reactive gases.

This resistance prevents the material from degrading rapidly when exposed to oxygen or other oxidizing agents during the filtration process.

The Requirement for High-Temperature Regeneration

To make CNTs reusable, they must undergo regeneration to strip away the captured gases.

This process typically requires high-temperature conditions. While this demands energy input, the thermal stability of CNTs allows them to survive this heat without structural collapse.

This capability permits cyclic reuse, significantly extending the lifespan of the adsorbent compared to single-use materials.

Making the Right Choice for Your Goal

When evaluating whether CNTs are the correct solution for your gas removal requirements, consider your specific operational priorities.

- If your primary focus is Precision Removal: Utilize CNTs that have undergone specific surface modification (chemical or thermal) to target the exact molecular weight and chemistry of pollutants like benzene or dioxin.

- If your primary focus is Sustainability and Cost-Efficiency: Leverage the CNTs' strong oxidation resistance, which allows for high-temperature regeneration and cyclic reuse, reducing the need for frequent material replacement.

By exploiting the tunable surface chemistry and robust physical structure of carbon nanotubes, you can transform gas filtration from a passive trapping method into an active, regenerative purification process.

Summary Table:

| Feature | Benefit for Gas Adsorption | Industrial Impact |

|---|---|---|

| Pore Structure | Massive surface area relative to volume | Higher volume of captured gas molecules |

| Surface Groups | Chemical 'hooks' for organic molecules | Enhanced affinity for VOCs like benzene |

| Tunability | Custom chemical/thermal surface treatment | Targeted removal of specific pollutants |

| Oxidation Resistance | High stability in harsh environments | Material longevity under reactive conditions |

| Thermal Stability | Enables high-temperature regeneration | Cost-effective cyclic reuse and sustainability |

Ready to advance your material science research? KINTEK provides the cutting-edge tools needed to master carbon nanotube applications. Backed by expert R&D and precision manufacturing, we offer high-performance CVD systems specifically designed for carbon nanotube synthesis, along with Muffle, Tube, and Vacuum furnaces for critical thermal treatment and regeneration processes. Whether you are targeting specific VOC removal or optimizing industrial sustainability, our customizable lab solutions are built to meet your unique needs. Consult with a KINTEK expert today to enhance your filtration efficiency.

Visual Guide

References

- Reena Reena. Role of nanomaterials in the environment. DOI: 10.33545/26648776.2025.v7.i2b.100

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Magnesium Extraction and Purification Condensing Tube Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

People Also Ask

- How is an industrial high-temperature furnace utilized for beta-quench treatment of Zr-2.5%Nb alloys?

- What is the primary objective of processing high-purity quartz? Achieve 99.998% Purity for Tech Applications

- Why is pre-sintering of Ga2O3 raw material powder required? Unlock Beta-Phase Stability for High-Performance Thin Films

- How do structured computational grids facilitate the simulation of complex geometric boundaries? Master Furnace Design

- How does a constant temperature and humidity curing chamber contribute to GCCM hydration? Optimize Material Strength

- How does an infrared rapid thermal annealing belt furnace affect battery performance? Maximize Efficiency Today

- What are the requirements for synthesizing Magnesium alloys via ampoule method? Expert Synthesis Protocols

- What functions does glucose perform in lithium-ion sieve synthesis? Enhance Carbothermal Reduction for LiMnO2 Purity