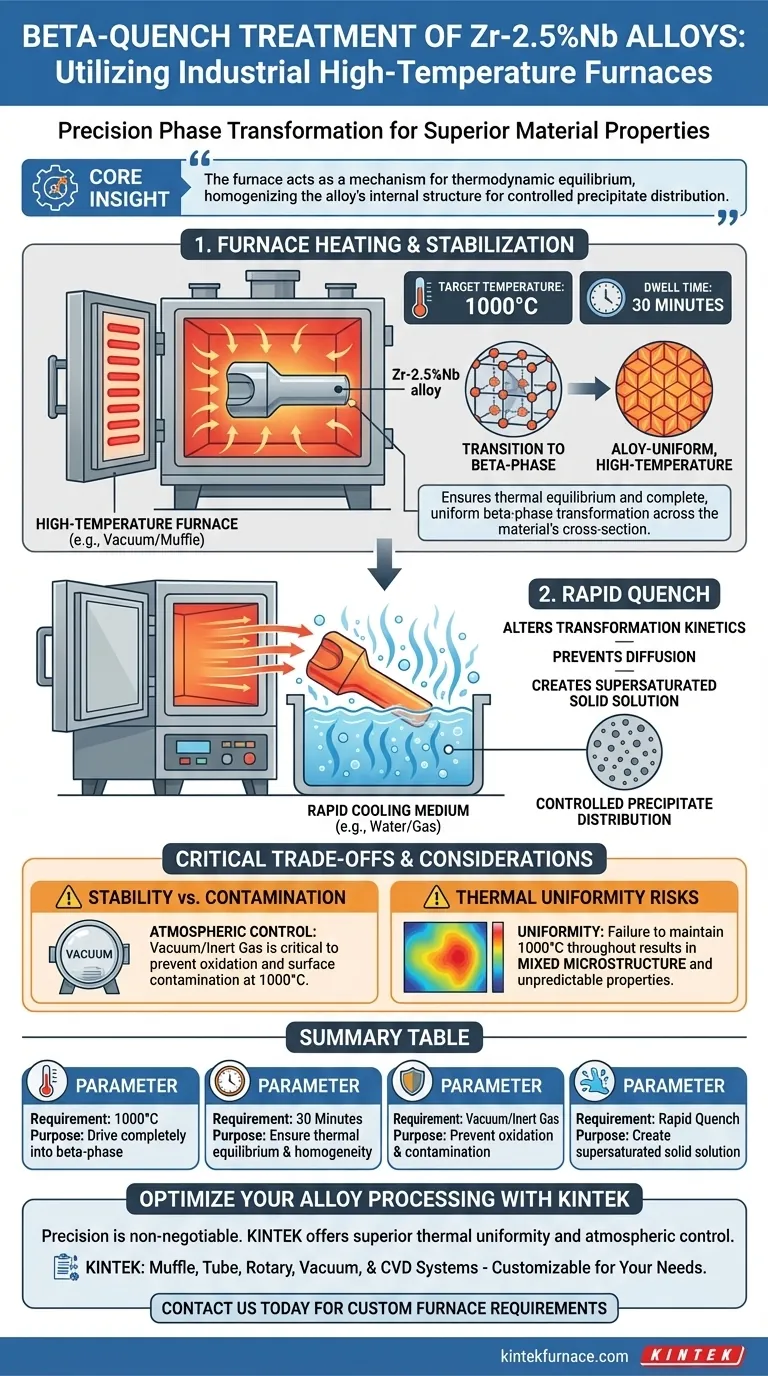

An industrial high-temperature furnace functions as a precision environment to force phase transformation in Zr-2.5%Nb alloys, specifically by maintaining a stable temperature of 1000°C for a duration of 30 minutes. This controlled heating period is essential to drive the alloy completely into the beta-phase region, acting as the prerequisite step before rapid cooling locks in the desired supersaturated solid solution structure.

Core Insight The furnace is not merely a heating element; it is a mechanism for thermodynamic equilibrium. By sustaining a specific temperature and dwell time, it homogenizes the alloy's internal structure, enabling the subsequent quench to effectively control the distribution of precipitate phases and define the material's final properties.

The Mechanics of Beta-Phase Stabilization

The primary role of the furnace in this treatment is to alter the crystalline structure of the zirconium alloy through precise thermal application.

Reaching the Beta-Phase Region

To achieve the necessary microstructural change, the furnace must elevate the alloy's temperature to 1000°C. At this specific thermal threshold, the Zr-2.5%Nb alloy transitions into the beta-phase, a high-temperature crystal structure distinct from its room-temperature state.

The Importance of Dwell Time

Reaching temperature is not enough; the furnace must maintain this environment for 30 minutes. This "holding" or dwell period ensures that the entire cross-section of the material—not just the surface—reaches thermal equilibrium. It guarantees that the transformation to the beta-phase is complete and uniform throughout the component.

Conditioning for the Quench

The furnace treatment is the setup; the quench is the trigger. The furnace prepares the atomic structure for the rapid cooling that follows.

Altering Transformation Kinetics

By holding the alloy in the beta-phase, the furnace sets the stage for rapid cooling. When the material is removed from the stable furnace environment and quenched, the sudden drop in temperature prevents the atoms from diffusing back to their equilibrium positions.

Creating a Supersaturated Solid Solution

The combination of furnace heating and subsequent quenching traps the alloying elements in a supersaturated solid solution. This non-equilibrium structure is critical because it creates a specific atomic arrangement that would not exist if the material were allowed to cool slowly in the furnace.

Controlling Precipitate Distribution

The ultimate goal of this thermal cycle is to dictate the distribution of precipitate phases. By ensuring a complete entry into the beta-phase within the furnace, engineers can predict and control how these strengthening particles disperse, directly influencing the alloy's mechanical performance.

Critical Trade-offs and Considerations

While the primary reference focuses on temperature and time, industrial application requires managing external variables.

Stability vs. Contamination

Industrial furnaces, particularly vacuum or muffle types, are designed to minimize surface contamination. Zirconium alloys are reactive at high temperatures; therefore, the furnace must provide an environment (often vacuum or inert gas) that prevents oxidation while maintaining the strict 1000°C requirement.

Thermal Uniformity Risks

If the furnace fails to maintain the 1000°C target across the entire workload, the alloy may not fully enter the beta-phase. This results in a mixed microstructure after quenching, leading to unpredictable mechanical properties and inconsistent precipitate distribution.

Ensuring Process Success

To effectively utilize a high-temperature furnace for Zr-2.5%Nb alloys, you must align the equipment capabilities with your material goals.

- If your primary focus is Structural Homogeneity: Ensure the furnace can hold a strictly uniform 1000°C for the full 30 minutes to guarantee complete beta-phase transformation.

- If your primary focus is Material Hardness and Strength: Prioritize the transfer speed from the furnace to the cooling medium to maximize the formation of the supersaturated solid solution.

Success in beta-quenching lies in the precision of the heating cycle, as it defines the potential of the final microstructure.

Summary Table:

| Process Parameter | Requirement | Purpose in Beta-Quench Treatment |

|---|---|---|

| Target Temperature | 1000°C | Drive alloy completely into the beta-phase region |

| Dwell Time | 30 Minutes | Ensure thermal equilibrium and structural homogeneity |

| Atmosphere | Vacuum/Inert Gas | Prevent oxidation and surface contamination of Zr-alloys |

| Post-Heating Action | Rapid Quench | Create supersaturated solid solution and control precipitates |

Optimize Your Alloy Processing with KINTEK

Precision is non-negotiable when performing beta-quench treatments on sensitive materials like Zr-2.5%Nb. At KINTEK, we understand that maintaining a strict 1000°C environment requires superior thermal uniformity and atmospheric control.

Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, and CVD systems, all customizable for your unique laboratory or industrial needs. Whether you are stabilizing beta-phases or developing new superalloys, our high-temperature furnaces provide the reliability you need to lock in perfect material properties every time.

Ready to elevate your material science? Contact us today to discuss your custom furnace requirements.

Visual Guide

References

- Arnomitra Chatterjee, R.N. Singh. Exploring Anisotropy in Zr-2.5%Nb Pressure Tube Material through Hardness Measurements: Role of Microstructure and Hydrogen Concentration. DOI: 10.1007/s11665-025-11744-y

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- How does a cooling circulation unit assist in plastic pyrolysis? Optimize Bio-Oil & Gas Separation

- Why is an electric heating furnace integrated with a capsule-piercing reactor? Ensure Precise Fluid Analysis

- Why is it necessary to bake substrates in an industrial oven prior to silver nanoparticle ink spin coating?

- How does a high-precision temperature control system assist in evaluating the thermal management capabilities of phosphor materials? Pinpoint Performance for Solar Cells.

- How do high-power IR furnaces compare to traditional equipment for nanocomposites? Unlock Superior Material Control

- Why is instantaneous heating required for N-GC-X catalyst synthesis? Achieve Superior 2D Nanosheet Morphology

- What are the advantages of using microwave plasma for aluminum powder reduction? Achieve Unmatched Material Purity

- How does metallic magnesium facilitate deep purification of molten chloride salts at 800 °C? Achieve Ultra-High Purity