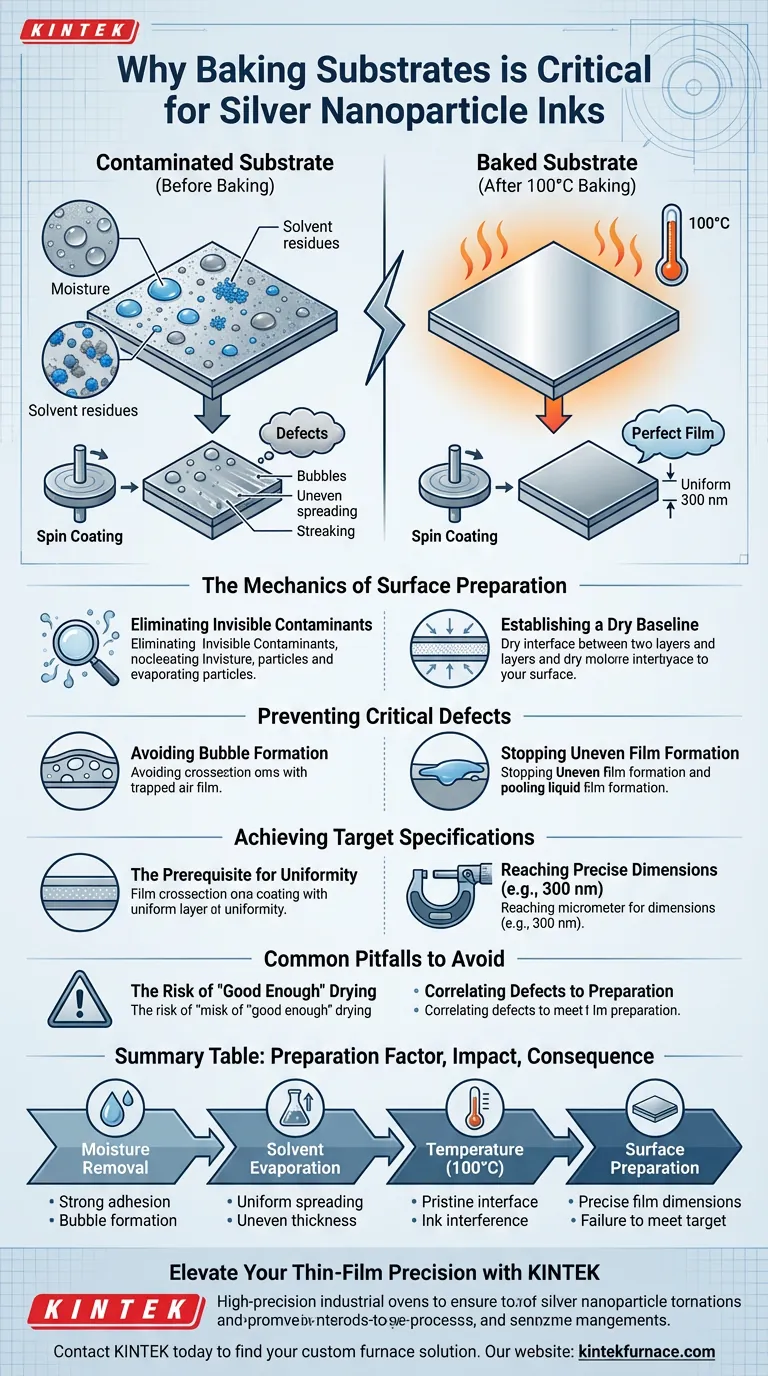

Baking the substrate is a critical preparatory step essential for ensuring the adhesion and quality of silver nanoparticle inks. This process, typically performed in an industrial oven at 100 °C, is necessary to completely eliminate residual moisture and solvents that cling to the substrate surface.

Without a perfectly dry surface, the subsequent spin coating process is compromised, leading to structural defects that make high-precision film fabrication impossible.

The Mechanics of Surface Preparation

Eliminating Invisible Contaminants

Substrates often carry microscopic layers of residual moisture or solvents that are not visible to the naked eye.

High-temperature baking effectively evaporates these contaminants. By exposing the substrate to 100 °C, you ensure the surface is chemically and physically prepared to receive the ink.

Establishing a Dry Baseline

The goal is to create a pristine, dry interface between the substrate and the silver nanoparticle ink.

Any remaining liquid particles can interfere with the surface tension and spreading mechanics of the ink during the high-speed spin coating process.

Preventing Critical Defects

Avoiding Bubble Formation

If moisture remains on the substrate, the dynamics of spin coating can trap these volatile pockets.

This leads to the formation of bubbles within the ink layer. These bubbles disrupt the conductivity and structural integrity of the final film.

Stopping Uneven Film Formation

Solvent residues cause the ink to spread unpredictably.

Instead of a smooth, continuous layer, the ink may pool or streak, resulting in uneven film formation. This unevenness compromises the electrical performance of the silver nanoparticles.

Achieving Target Specifications

The Prerequisite for Uniformity

To achieve a high-quality thin film, the coating process must be flawless.

A baked, dry substrate is the absolute prerequisite for depositing a layer with uniform thickness.

Reaching Precise Dimensions

For applications requiring specific dimensions, such as a 300 nm thickness, variable surface conditions are unacceptable.

Baking ensures that the spin coating parameters yield consistent, repeatable results, allowing the film to meet these exact specifications.

Common Pitfalls to Avoid

The Risk of "Good Enough" Drying

It is a common error to assume air drying or lower temperatures are sufficient.

Failing to reach the 100 °C threshold or baking for insufficient time leaves trace moisture, which is enough to ruin the uniformity of the film.

Correlating Defects to Preparation

When bubbles or unevenness appear in the final product, the issue is often misdiagnosed as an ink or spin-speed problem.

In reality, these defects are almost always symptoms of insufficient substrate baking prior to coating.

Ensuring Process Integrity

To maximize yield and film performance, align your preparation steps with your specific manufacturing goals:

- If your primary focus is Film Homogeneity: Ensure the oven reaches a steady 100 °C to prevent solvent-induced streaking or pooling.

- If your primary focus is Structural Integrity: Prioritize complete moisture removal to eliminate the risk of bubble formation within the layer.

A strictly controlled baking phase is the invisible foundation of a flawless silver nanoparticle application.

Summary Table:

| Preparation Factor | Impact on Quality | Consequence of Failure |

|---|---|---|

| Moisture Removal | Ensures strong ink adhesion | Bubble formation & structural defects |

| Solvent Evaporation | Promotes uniform ink spreading | Uneven film thickness & pooling |

| Temperature (100 °C) | Establishes a pristine interface | Incomplete drying & ink interference |

| Surface Preparation | Enables precise film dimensions | Failure to meet target specifications (e.g., 300 nm) |

Elevate Your Thin-Film Precision with KINTEK

Don't let substrate contaminants compromise your research or production yield. KINTEK’s high-precision industrial ovens provide the thermal stability and uniformity required to ensure a perfectly dry baseline for silver nanoparticle ink applications.

Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, and CVD systems, all customizable to meet your unique lab requirements. Whether you are aiming for 300 nm uniformity or complex high-temp material synthesis, our equipment is built to deliver repeatable excellence.

Ready to optimize your spin coating process? Contact KINTEK today to find your custom furnace solution.

Visual Guide

References

- Hyeong-Jin Park, Seung Jae Moon. Physical Characteristics of Sintered Silver Nanoparticle Inks with Different Sizes during Furnace Sintering. DOI: 10.3390/ma17050978

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1200℃ Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- How do industrial heat treatment furnaces ensure 55Si2 spring steel stability? Optimize Your Tempering Process

- What are the differences between gravity and mechanical convection in laboratory furnaces? Choose the Right Type for Your Lab

- What advantages does a vacuum drying oven offer? Superior Chemical Stability & Efficient Dehydration

- What is the primary function of a high-purity inert glove box? Ensure Success in LiF-BeF2 Molten Salt Systems

- What is the purpose of annealing the sapphire substrate at 980 °C with Cr? Achieve Unidirectional Cr2S3 Growth

- What is the primary function of a forced convection oven in plant sample preparation? Ensure Accurate Data Every Time

- How does rapid water cooling equipment contribute to the stability of the foaming agent in aluminum foam precursors?

- How does a high-temperature sintering furnace influence ZnO nanotube sensors? Unlock Peak Sensitivity and Stability