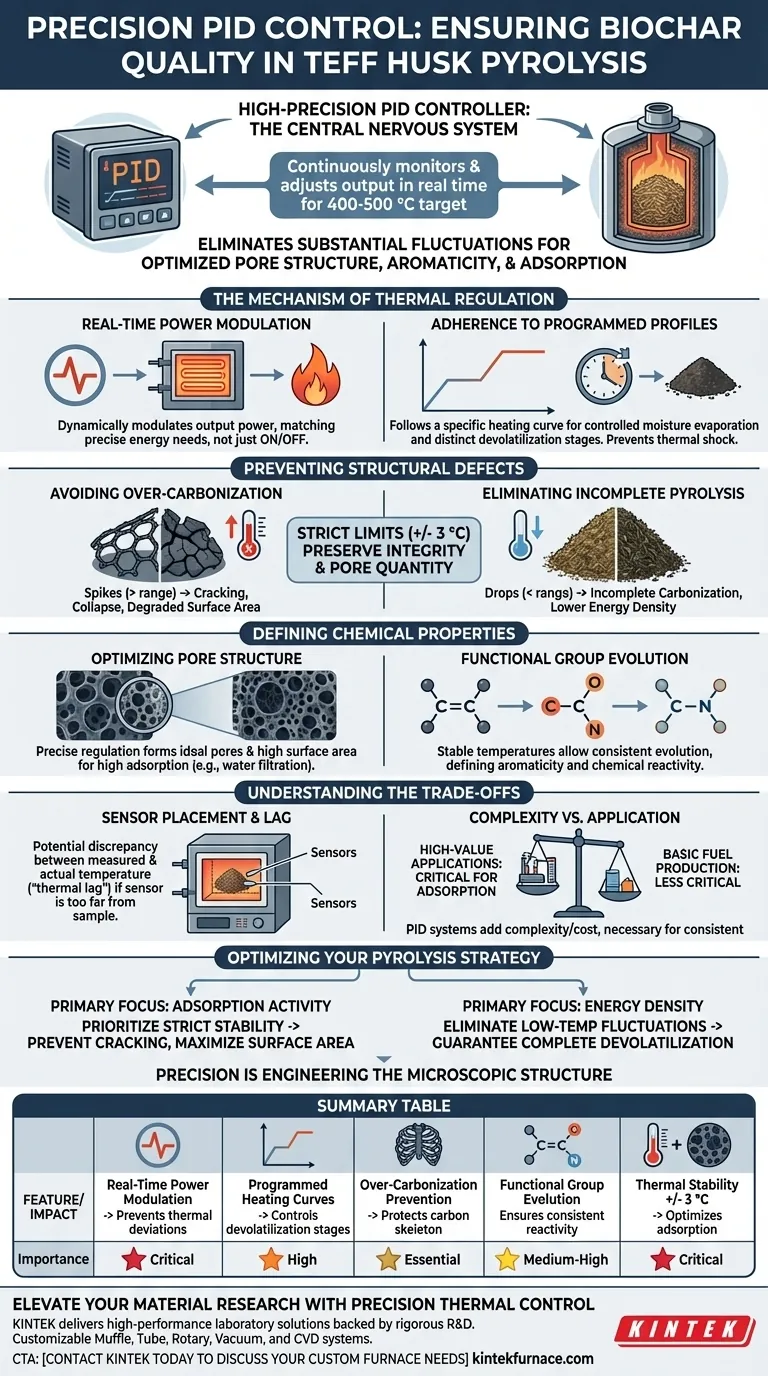

A high-precision PID temperature controller acts as the central nervous system of the pyrolysis reactor, utilizing proportional-integral-derivative algorithms to continuously monitor and adjust the heating element's output power in real time. For the pyrolysis of teff husk, this technology ensures the internal reactor temperature strictly aligns with programmed targets—typically between 400 and 500 °C—thereby preventing thermal deviations that lead to inconsistent material quality.

By eliminating substantial temperature fluctuations, high-precision control stabilizes the physical and chemical transformation of the biomass. This thermal stability is the defining factor in optimizing the biochar’s pore structure, aromaticity, and overall adsorption capacity.

The Mechanism of Thermal Regulation

Real-Time Power Modulation

The core function of the PID controller is to bridge the gap between the current reactor temperature and the desired setpoint.

It does not simply turn the heat on or off; instead, it dynamically modulates the output power of the electric heating furnace.

This ensures that the heat input matches the precise energy required to maintain the specific pyrolysis temperature of teff husk.

Adherence to Programmed Profiles

Biochar quality depends on following a specific temperature ramp, not just hitting a final number.

The controller ensures the system follows a programmed heating curve, allowing for controlled moisture evaporation and distinct stages of devolatilization.

This adherence prevents thermal shock, which can alter the mass loss characteristics of the teff husk.

Preventing Structural Defects

Avoiding Over-Carbonization

If temperatures spike beyond the programmed range, the carbon skeleton of the biomass can crack or collapse.

The primary reference notes that precision control prevents these fluctuations, protecting the structural integrity of the material.

Supplementary data indicates that maintaining temperatures within strict limits (e.g., +/- 3 °C) is vital to preventing the degradation of surface area and pore quantity.

Eliminating Incomplete Pyrolysis

Conversely, drops in temperature result in incomplete carbonization.

Without sufficient consistent heat, the volatile matter in the teff husk does not fully decompose.

This results in a product with lower energy density and unstable physical properties, rendering it less effective for industrial or agricultural use.

Defining Chemical Properties

Optimizing Pore Structure

The stability provided by the PID controller directly influences the development of the biochar's internal architecture.

Precise thermal regulation ensures the formation of an ideal pore structure and high surface area.

This is critical for applications requiring high adsorption activity, such as water filtration or soil amendment.

Functional Group Evolution

The chemical makeup of biochar changes rapidly during the devolatilization phase.

Stable temperatures allow for the consistent evolution of chemical functional groups, including C=C, C-O, and C-N bonds.

Preserving these groups determines the aromaticity and chemical reactivity of the final teff husk biochar.

Understanding the Trade-offs

Sensor Placement and Lag

While PID algorithms are highly accurate, they rely entirely on the data provided by thermal sensors.

If the sensor is placed too far from the teff husk sample (e.g., near the heating element rather than the sample core), there may be a discrepancy between the measured and actual temperature.

This "thermal lag" can lead to a false sense of precision, where the controller stabilizes the furnace air rather than the biomass itself.

Complexity vs. Application

High-precision PID systems add complexity and cost to the reactor setup.

For basic fuel production where specific pore structure is less critical, this level of precision might yield diminishing returns.

However, for high-value applications requiring specific adsorption capabilities, the trade-off in cost is necessary to ensure consistent quality.

Optimizing Your Pyrolysis Strategy

To extract the maximum value from teff husk pyrolysis, align your thermal control strategy with your end goal:

- If your primary focus is Adsorption Activity: Prioritize strict temperature stability to prevent carbon skeleton cracking and maximize surface area.

- If your primary focus is Energy Density: Ensure the controller eliminates low-temperature fluctuations to guarantee complete devolatilization of the biomass.

Precision in temperature control is not just about heating; it is about engineering the microscopic structure of the final product.

Summary Table:

| Feature | Impact on Biochar Quality | Importance Level |

|---|---|---|

| Real-Time Power Modulation | Prevents thermal deviations and ensures consistent carbonization. | Critical |

| Programmed Heating Curves | Controls devolatilization stages and prevents structural thermal shock. | High |

| Over-Carbonization Prevention | Protects the carbon skeleton and preserves surface area/pore quantity. | Essential |

| Functional Group Evolution | Ensures consistent aromaticity and chemical reactivity (C=C, C-O bonds). | Medium-High |

| Thermal Stability (+/- 3 °C) | Optimizes adsorption capacity for high-value industrial applications. | Critical |

Elevate Your Material Research with Precision Thermal Control

Achieving the perfect biochar structure requires more than just heat—it requires the absolute thermal precision that only expert engineering can provide. KINTEK delivers high-performance laboratory solutions backed by rigorous R&D and world-class manufacturing.

Whether you are processing teff husk or advanced composites, our Muffle, Tube, Rotary, Vacuum, and CVD systems are fully customizable to meet your specific temperature ramp and stability requirements. Don't let thermal fluctuations compromise your results.

Contact KINTEK today to discuss your custom furnace needs and discover how our precision technology can optimize your production quality.

Visual Guide

References

- Marcin Landrat, Semira Seyid. Assessing the Potential of Teff Husk for Biochar Production through Slow Pyrolysis: Effect of Pyrolysis Temperature on Biochar Yield. DOI: 10.3390/en17091988

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Small Rotary Kiln Calciner

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant Rotating Furnace

- Cylindrical Resonator MPCVD Machine System for Lab Diamond Growth

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

People Also Ask

- Why is vacuum freeze-drying necessary for FeNC/MXene catalysts? Preserving 2D Architecture for Peak Performance

- What is the function of a ball mill in the raw material pretreatment stage for the szaibelyite vacuum thermal reduction process?

- Why is annealing considered a core process in perovskite solar cell manufacturing? Unlock Peak Efficiency

- What features can be adjusted in laboratory furnaces based on application requirements? Optimize Your Lab's Thermal Processing

- What are the advantages of Spark Plasma Sintering (SPS) for diffusion bonding? Precision in Atomic Diffusion

- Why is it necessary to connect a pyrolyser online with a GC-MS? Achieve High-Fidelity RDF Analysis

- Why is a high-precision heating/cooling stage important for 2D In2Se3 studies? Secure Precise Phase Transition Data

- Why is a 1200°C hold required for Ti(C,N)-FeCr sintering? Unlock Superior Material Density