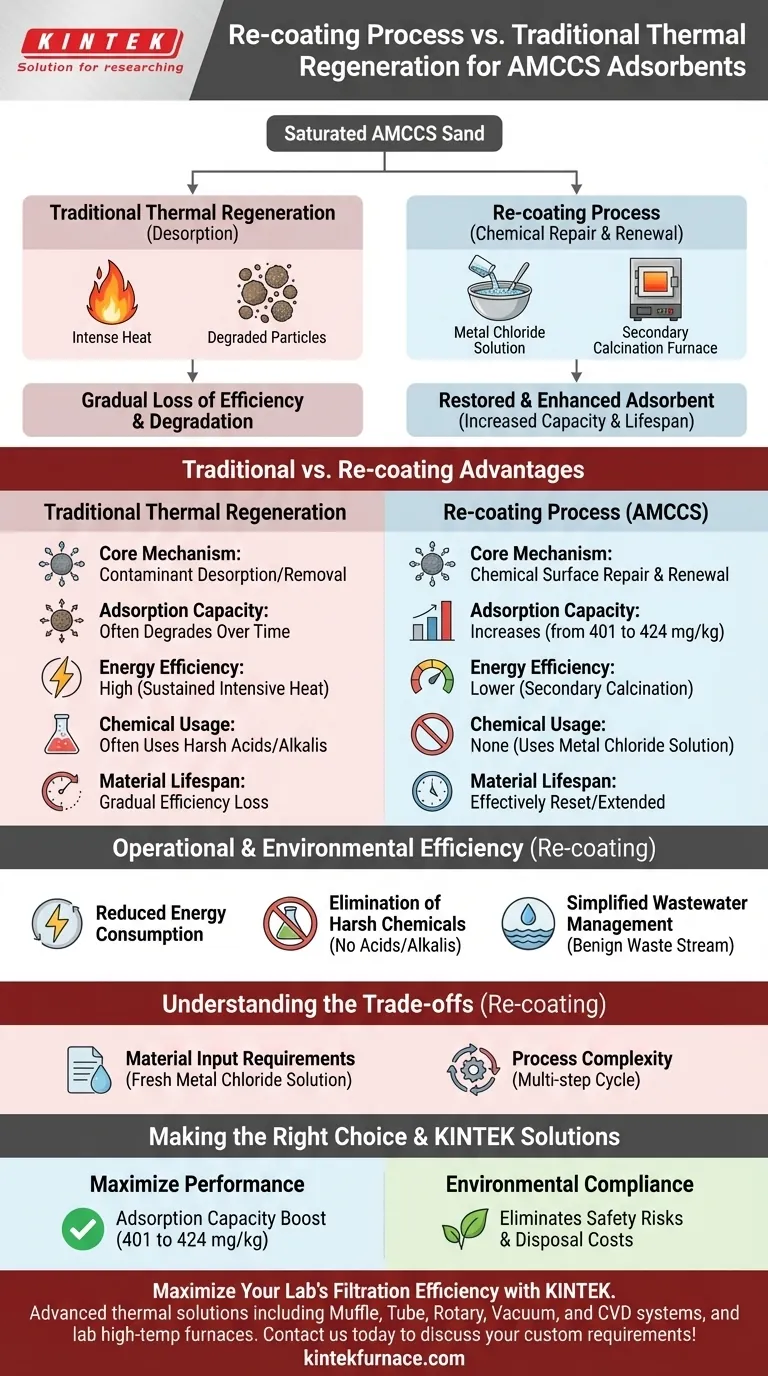

The re-coating process offers a distinct advantage over traditional methods by chemically repairing the adsorbent surface rather than simply desorbing pollutants. By re-mixing saturated sand grains into the original metal chloride solution followed by secondary calcination, this technique renews damaged active sites. This results in a regenerated material that not only recovers its function but can potentially exceed its original performance specifications.

Unlike standard regeneration which often degrades material over time, re-coating acts as a restorative process. It increases adsorption capacity beyond the original baseline while simultaneously reducing energy usage and wastewater treatment burdens.

Enhancing Adsorbent Performance

Restoration of Active Sites

Traditional regeneration methods typically focus on removing the contaminant from the pore structure. However, the re-coating process goes a step further by repairing the active sites on the sand grains.

Increased Adsorption Capacity

The most significant technical advantage is the potential for performance gains. While the original Aluminum-Magnesium-Calcium Coated Sand (AMCCS) has an adsorption capacity of 401 mg/kg, the re-coated material can reach 424 mg/kg.

Extending Material Lifespan

Because the process renews the chemical coating, it effectively resets the lifespan of the media. This prevents the gradual loss of efficiency common in adsorbents subjected to repeated thermal cycling alone.

Operational and Environmental Efficiency

Reduced Energy Consumption

Compared to traditional physical regeneration, which often requires sustained high temperatures to drive off adsorbed compounds, the re-coating method is more energy-efficient. The secondary calcination required for re-coating consumes less energy than the intensive heat treatment used in standard thermal regeneration.

Elimination of Harsh Chemicals

Many chemical regeneration protocols rely on strong acids or alkaline solutions to strip contaminants. The re-coating process avoids these hazardous materials entirely.

Simplified Wastewater Management

By eliminating the need for strong acids and alkalis, the process generates a more benign waste stream. This directly reduces the complexity and cost associated with downstream wastewater treatment.

Understanding the Trade-offs

Material Input Requirements

While energy consumption is lower, this process does introduce a material dependency. Re-coating requires a fresh supply of the metal chloride solution to facilitate the re-mixing stage.

Process Complexity

This is not a simple "bake-out" procedure. It involves a multi-step cycle of re-mixing in solution followed by calcination, which may require more complex handling equipment than a standard thermal desorption unit.

Making the Right Choice for Your Goal

To determine if the re-coating process aligns with your operational objectives, consider the following:

- If your primary focus is maximizing performance: The re-coating process is the superior choice, as it is capable of boosting adsorption capacity from 401 mg/kg to 424 mg/kg.

- If your primary focus is environmental compliance: This method is preferable as it eliminates the safety risks and disposal costs associated with strong acid or alkaline regeneration solutions.

The re-coating process transforms regeneration from a maintenance task into a value-added step that enhances the adsorbent's fundamental capabilities.

Summary Table:

| Feature | Traditional Thermal Regeneration | Re-coating Process (AMCCS) |

|---|---|---|

| Core Mechanism | Contaminant desorption/removal | Chemical surface repair & renewal |

| Adsorption Capacity | Often degrades over time | Increases (from 401 to 424 mg/kg) |

| Energy Efficiency | High (sustained intensive heat) | Lower (secondary calcination) |

| Chemical Usage | Often uses harsh acids/alkalis | None (uses metal chloride solution) |

| Material Lifespan | Gradual efficiency loss | Effectively reset/extended |

Maximize Your Lab’s Filtration Efficiency with KINTEK

Elevate your research and industrial processes with advanced thermal solutions designed for high-performance regeneration. Backed by expert R&D and manufacturing, KINTEK offers a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, along with specialized lab high-temp furnaces—all fully customizable to meet your unique AMCCS or material processing needs.

Whether you are looking to boost adsorption capacity or optimize your calcination cycle, our technical team provides the precision equipment required to achieve superior results.

Ready to upgrade your laboratory capabilities? Contact us today to discuss your custom furnace requirements!

Visual Guide

References

- Kiana Modaresahmadi, James M. Wescott. Defluoridation of Water Using Al-Mg-Ca Ternary Metal Oxide-Coated Sand in Adsorption Column Study. DOI: 10.3390/separations12050119

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Molybdenum Disilicide MoSi2 Thermal Heating Elements for Electric Furnace

- Magnesium Extraction and Purification Condensing Tube Furnace

People Also Ask

- Why is temperature control accuracy critical for K439B superalloy? Master 1160°C Solution Treatment

- What is the purpose of using a preheated stainless steel plate when processing molten glass? Avoid Thermal Stress.

- What are the functions of a programmed temperature rise experimental system? Master Coal Pre-Oxidation Research

- Why is a constant temperature and humidity curing chamber essential for geopolymerization? Ensure Structural Strength

- What role does an industrial-grade POCl3 diffusion furnace system play in DOSS? Master Quantitative Phosphorus Control

- What conditions does an autoclave provide for MoS2 hydrothermal synthesis? Achieve Optimal MoS2 Nanosheet Growth

- How does a vacuum drying oven contribute to the quality of crosslinked precursors? Expert Guide to Material Integrity

- How is mechanochemical grinding used in lithium battery recovery? Unlock Efficient Solid-State Material Repair