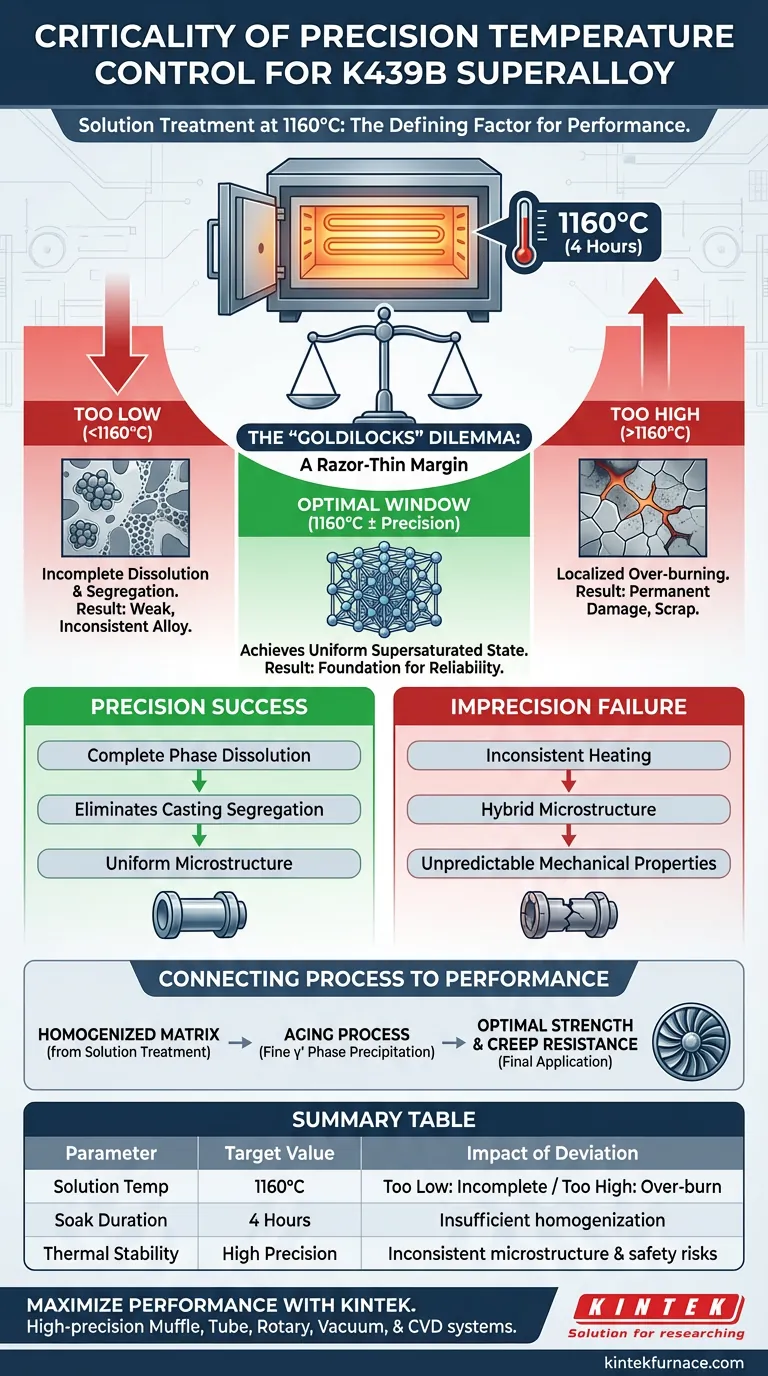

Precision temperature control is the defining factor in successfully processing the K439B superalloy. During solution treatment, the furnace must maintain a rigid environment of 1160°C for four hours to fully dissolve strengthening phases into the matrix without crossing the threshold into localized over-burning. This accuracy is the only way to eliminate casting segregation and prepare the alloy for optimal mechanical performance.

Core Takeaway The solution treatment process operates on a razor-thin margin: the temperature must be high enough to homogenize the alloy's structure, yet stable enough to avoid irreversible thermal damage. A high-precision furnace acts as the safeguard, ensuring the material achieves a uniform supersaturated state essential for future strengthening.

The Critical Role of Thermal Stability

Achieving Complete Phase Dissolution

The primary objective of the solution treatment is to dissolve the alloy's strengthening phases completely into the matrix. This requires sustaining a specific temperature of 1160°C.

If the temperature fluctuates below this target, dissolution remains incomplete. This leaves the material chemically unbalanced, preventing the formation of the supersaturated solid solution required for high performance.

Eliminating Casting Segregation

Cast alloys naturally contain segregation—areas where chemical composition varies. The solution treatment is the "reset" button that eliminates these inconsistencies.

Precise thermal exposure facilitates the diffusion of elements, smoothing out these gradients. This creates a homogeneous structure, which is the foundation for the alloy's structural integrity.

The Risks of Imprecise Heating

Preventing Localized Over-burning

The upper limit of the temperature window is unforgiving. If the furnace control wavers and temperature spikes, the alloy suffers localized over-burning.

This phenomenon involves incipient melting at grain boundaries, which permanently degrades the material. Once over-burning occurs, the component is often unrecoverable and must be scrapped.

Avoiding Inconsistent Microstructure

Fluctuations create a hybrid microstructure where some areas are treated correctly, and others are not.

This lack of uniformity leads to unpredictable mechanical properties. In a high-performance superalloy like K439B, predictability is synonymous with safety.

Connecting Process to Performance

Preparing for Precipitation

Solution treatment is not an isolated step; it is the prerequisite for subsequent aging processes. It establishes the basis for the precipitation of fine, uniform strengthening phases.

By ensuring the matrix is perfectly homogenized first, the furnace enables the later formation of spherical $\gamma'$ phases (as seen in subsequent aging steps). If the solution treatment is flawed, the size and volume fraction of these phases cannot be effectively regulated later.

Ensuring Creep Resistance

The ultimate goal of processing K439B is to optimize mechanical strength and creep resistance.

Any compromise in the solution treatment temperature propagates through the manufacturing chain. A thermally accurate solution treatment ensures the alloy can survive the rigorous conditions of its final application.

Understanding the Trade-offs

The "Goldilocks" Dilemma

Operating at 1160°C presents a fundamental trade-off between homogenization and structural integrity.

Too Low: You preserve the grain boundaries but fail to remove segregation, resulting in a weak, inconsistent alloy.

Too High: You achieve rapid homogenization but risk catastrophic over-burning, rendering the part useless.

Equipment Capability vs. Process Risk

Standard furnaces often lack the feedback loops necessary to hold such a tight tolerance over a four-hour soak.

Using equipment with lower precision increases the risk of "thermal drift." Even a brief excursion outside the allowable range can invalidate the entire heat treatment cycle.

Making the Right Choice for Your Goal

To maximize the potential of K439B, you must align your equipment capabilities with your metallurgical objectives.

- If your primary focus is Structural Homogeneity: Prioritize a furnace with multi-zone control to prevent cold spots that leave casting segregation intact.

- If your primary focus is Scrap Reduction: Ensure your furnace features rapid-response overshoot protection to prevent temperature spikes that cause over-burning.

- If your primary focus is Downstream Performance: Verify that your solution treatment creates a pristine supersaturated solid solution to maximize the effectiveness of subsequent aging cycles.

Precision at 1160°C is not just a process parameter; it is the guarantee of the alloy's future reliability.

Summary Table:

| Process Parameter | Target Value | Impact of Deviation |

|---|---|---|

| Solution Temp | 1160°C | Too Low: Incomplete phase dissolution / Too High: Localized over-burning |

| Soak Duration | 4 Hours | Insufficient time prevents chemical homogenization |

| Thermal Stability | High Precision | Fluctuations cause inconsistent microstructure and safety risks |

| Primary Goal | Supersaturated State | Foundation for fine $\gamma'$ phase precipitation during aging |

Maximize Your Superalloy Performance with KINTEK

Precision at 1160°C is the difference between a high-performance component and a scrapped part. Backed by expert R&D and manufacturing, KINTEK offers high-precision Muffle, Tube, Rotary, Vacuum, and CVD systems designed to meet the rigorous thermal stability requirements of K439B superalloy processing.

Our lab high-temperature furnaces are fully customizable to eliminate thermal drift and ensure uniform heating for your unique research or production needs. Don't compromise on metallurgical integrity—contact our experts today to find the perfect furnace solution for your laboratory.

Visual Guide

References

- Yidong Wu, Xidong Hui. Evolution of Stress Rupture Property for K439B Superalloy During Long-Term Thermal Exposure at 800 °C. DOI: 10.3390/met14121461

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

People Also Ask

- What are the main types of heat treatment furnaces? Choose the Right Furnace for Your Lab or Industry

- What features can be adjusted in laboratory furnaces based on application requirements? Optimize Your Lab's Thermal Processing

- What physical characteristics of high-precision heating equipment are used in CSE selenium recycling?

- What are the equipment requirements for o-LISO ceramic sintering? Achieve 1050°C Precision for High Conductivity

- What are the specific equipment operational requirements for the SRS process? Unlock Precise Strain Engineering

- What type of furnace was chosen for annealing silicon-based materials and what were the key requirements? Discover the Ideal Solution for Precise Heat Treatment

- How is a mass spectrometer utilized in TPO tests for catalysts? Enhance Your Material Characterization

- How is an industrial heating furnace used for 20MnCr gear steel normalization? Master Microstructural Integrity