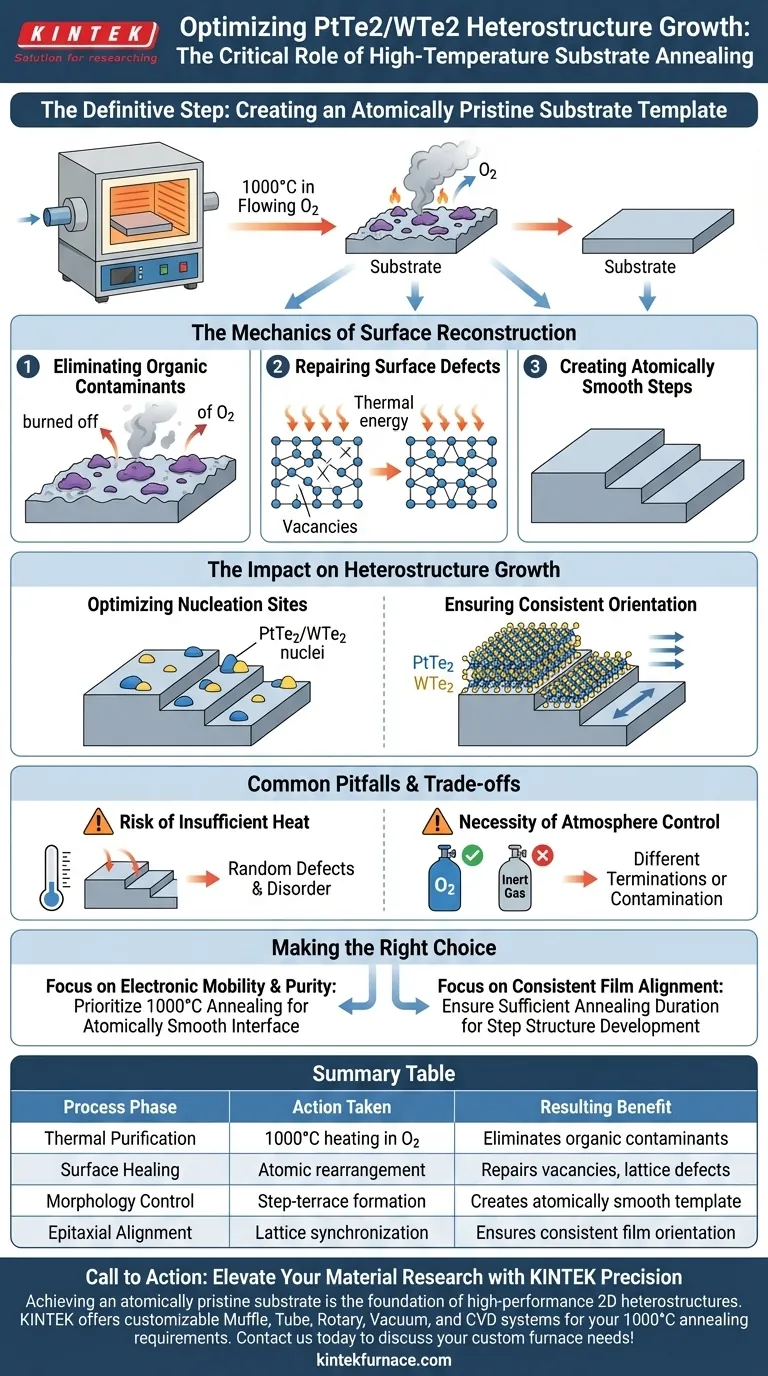

High-temperature annealing is the definitive step for creating an atomically pristine substrate surface, which is a prerequisite for high-quality epitaxial growth. By heating the substrate to approximately 1000°C in flowing oxygen, you simultaneously eliminate organic contaminants and physically reconstruct the surface to repair atomic-level defects.

Core Takeaway The annealing process transforms a chemically impure and structurally irregular substrate into an atomically smooth template. This specific surface architecture provides the necessary "blueprint" for PtTe2 and WTe2 to nucleate efficiently and grow with a consistent crystallographic orientation.

The Mechanics of Surface Reconstruction

Eliminating Organic Contaminants

Standard cleaning methods often leave behind microscopic residues. High-temperature annealing acts as a final purification stage.

By flowing oxygen at 1000°C, any remaining organic contaminants on the substrate surface are effectively burned off. This ensures that the interface between the substrate and the subsequent material is chemically pure.

Repairing Surface Defects

Mechanical polishing or handling can introduce invisible defects, such as vacancies or scratches, into the substrate's crystal lattice.

The thermal energy provided during annealing allows surface atoms to rearrange themselves. This "healing" process fills vacancies and corrects irregularities, restoring the structural integrity of the crystal surface.

Creating Atomically Smooth Steps

The ultimate goal of this thermal treatment is morphological control.

The rearrangement of atoms results in a surface characterized by an atomically smooth step structure. These "steps" and flat "terraces" are crucial because they define how the next layer of material will attach to the surface.

The Impact on Heterostructure Growth

Optimizing Nucleation Sites

For 2D materials like PtTe2 and WTe2 to grow successfully, they require specific points to start forming—known as nucleation sites.

The step edges created during annealing serve as high-energy, ideal nucleation sites. Without these defined steps, nucleation occurs randomly, leading to poor film quality.

Ensuring Consistent Orientation

The arrangement of the substrate determines the arrangement of the film.

An annealed, step-structured surface forces the growing thin films to align with the substrate's crystal lattice. This ensures the PtTe2 and WTe2 layers maintain a consistent orientation across the entire sample, which is vital for the electronic performance of the heterostructure.

Common Pitfalls and Trade-offs

The Risk of Insufficient Heat

If the temperature is too low or the duration too short, the surface reconstruction will be incomplete.

This leaves behind random defects that act as "trap states" for charge carriers. Consequently, the overlaying material will likely suffer from poly-crystalline disorder rather than forming a single, continuous crystal.

The Necessity of Atmosphere Control

The presence of flowing oxygen is specific and critical.

Attempting this process in an uncontrolled atmosphere can lead to different surface terminations or further contamination. The oxygen aids in the removal of carbon-based impurities that inert gases might not effectively strip away.

Making the Right Choice for Your Goal

To maximize the quality of your PtTe2/WTe2 heterostructures, apply the following principles:

- If your primary focus is electronic mobility and purity: Prioritize the 1000°C annealing step to ensure an atomically smooth interface that minimizes electron scattering.

- If your primary focus is consistent film alignment: Ensure the annealing duration is sufficient (e.g., 3 hours) to fully develop the step structure that guides crystal orientation.

A pristine substrate is not merely a passive base; it is the active template that dictates the structural destiny of your entire device.

Summary Table:

| Process Phase | Action Taken | Resulting Benefit |

|---|---|---|

| Thermal Purification | 1000°C heating in O2 | Eliminates organic contaminants and carbon residues |

| Surface Healing | Atomic rearrangement | Repairs vacancies and mechanical lattice defects |

| Morphology Control | Step-terrace formation | Creates atomically smooth templates for nucleation |

| Epitaxial Alignment | Lattice synchronization | Ensures consistent crystallographic orientation of thin films |

Elevate Your Material Research with KINTEK Precision

Achieving an atomically pristine substrate is the foundation of high-performance 2D heterostructures. At KINTEK, we understand that your research demands uncompromising thermal accuracy and atmospheric control.

Backed by expert R&D and manufacturing, KINTEK offers a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems. Our lab high-temp furnaces are fully customizable to meet the specific 1000°C annealing requirements for your unique substrates, ensuring optimal nucleation and electronic mobility for your devices.

Ready to transform your material growth? Contact us today to discuss your custom furnace needs!

Visual Guide

References

- Yang Qu, Hyunsoo Yang. Field‐Free Spin–Orbit Torque Switching of Perpendicular Magnetization by PtTe <sub>2</sub> /WTe <sub>2</sub> Bilayers at Sub‐ns Timescales. DOI: 10.1002/adfm.202507988

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- Why are aluminum alloy castings subjected to high-temperature testing in an industrial blister oven? Reveal Defects

- Why is the purity of oxide precursors critical for ZnO-doped CuO? Ensure High Photocatalytic Performance

- How does an annealing furnace work? A Guide to Controlled Heat Treatment

- How does a single-roller melt-spinning system facilitate Fe-based amorphous alloys? Achieve Precision Rapid Quenching

- Why is staged temperature control required in industrial air drying ovens for carbon nanofibers? Key Safety Insights

- Why do high-performance Bi-2223 superconducting materials require high-precision temperature control? | KINTEK Solution

- What role does a high-temperature heating environment play in the hydrothermal synthesis of ZSM-5 zeolite crystals?

- What role does a vacuum oven play in determining the moisture content of mercury-depleted coal adsorbents? Key Insights