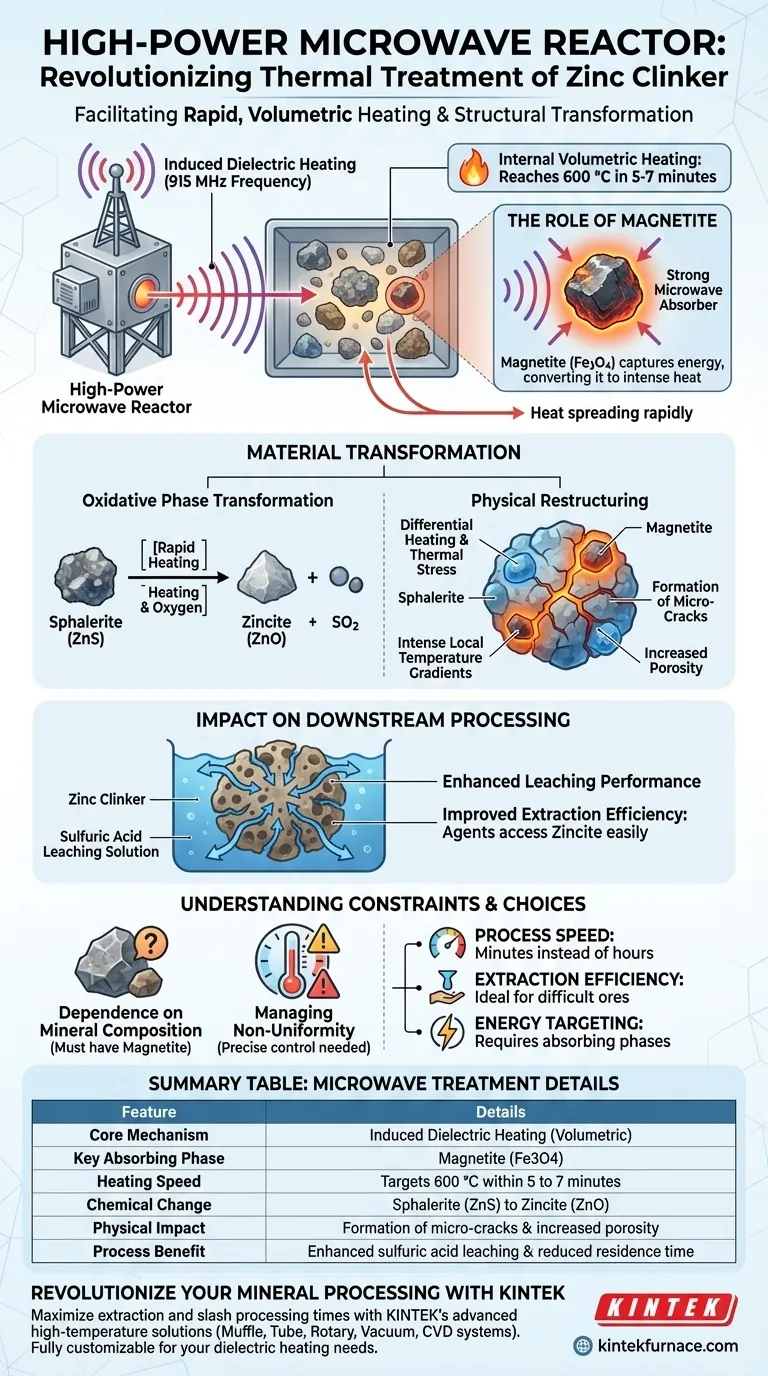

High-power microwave reactors facilitate thermal treatment by utilizing induced dielectric heating to rapidly elevate the temperature of zinc clinker. Specifically, systems operating at frequencies like 915 MHz target strong microwave-absorbing phases, such as magnetite, to reach 600 °C within 5 to 7 minutes. This rapid heating triggers the necessary oxidative phase transformation of sphalerite (ZnS) into zincite (ZnO) much faster than traditional methods.

By leveraging the unique thermal properties of specific mineral components, microwave heating replaces long-duration roasting with a rapid, volumetric process. This approach achieves two critical goals simultaneously: chemically converting sulfides to oxides and physically restructuring the material to enhance downstream extraction.

The Mechanism of Rapid Heating

Induced Dielectric Heating

Unlike conventional furnaces that heat from the outside in, a high-power microwave reactor generates heat internally.

It relies on induced dielectric heating, where microwave energy interacts directly with the material at the molecular level.

The Role of Magnetite

The efficiency of this process depends heavily on the presence of magnetite within the zinc clinker.

Magnetite acts as a strong microwave-absorbing phase, effectively capturing the energy and converting it into heat.

This allows the material to reach the target temperature of 600 °C in a fraction of the time required by traditional roasting.

Transforming the Material Structure

Oxidative Phase Transformation

The primary chemical goal of this thermal treatment is the conversion of zinc compounds.

The rapid heating drives a fast oxidative phase transformation, converting sphalerite (ZnS) into zincite (ZnO).

This conversion is essential for making the zinc chemically accessible for subsequent processing steps.

Differential Heating and Thermal Stress

Microwave heating does not affect all minerals equally.

Components like magnetite absorb energy readily, while minerals like sphalerite have significantly lower microwave absorption capacities and thermal conductivities.

This creates intense, non-uniform local temperature gradients within the clinker.

Formation of Micro-Cracks

The difference in heating rates generates substantial thermal stress inside the material.

These stresses fracture the material structure, leading to the formation of numerous micro-cracks.

This physical alteration increases the overall porosity of the zinc clinker.

Impact on Downstream Processing

Enhanced Leaching Performance

The micro-cracks generated during heating serve a functional purpose beyond just structural damage.

They create pathways that allow sulfuric acid leaching solutions to penetrate deeper into the material.

Improved Extraction Efficiency

By increasing porosity and surface area, the reactor ensures the leaching agents can access the zincite more easily.

This results in a more efficient extraction process compared to materials treated with conventional, uniform heating methods.

Understanding the Constraints

Dependence on Mineral Composition

The system's effectiveness is strictly tied to the mineralogy of your feedstock.

Because the process relies on differential absorption, the presence of a strong absorber like magnetite is non-negotiable.

Without these absorbing phases, the material may remain transparent to microwave energy, failing to heat effectively.

Managing Non-Uniformity

While non-uniform heating is beneficial for creating micro-cracks, it requires precise control.

The intense local temperature gradients must be managed to ensure the bulk material reaches the target temperature without creating hot spots that could damage the reactor or degrade the product.

Making the Right Choice for Your Goal

This technology represents a shift from passive external heating to active, material-specific interaction.

- If your primary focus is process speed: This method significantly reduces residence time, achieving phase transformation in minutes rather than hours.

- If your primary focus is extraction efficiency: The induced micro-cracking improves acid penetration, making this ideal for dense or refractory ores that are difficult to leach.

- If your primary focus is energy targeting: Ensure your feedstock contains sufficient microwave-absorbing phases (like magnetite) to catalyze the dielectric heating process.

Microwave thermal treatment turns the material’s own physical properties into the engine for its efficient processing.

Summary Table:

| Feature | Microwave Treatment Details |

|---|---|

| Core Mechanism | Induced Dielectric Heating (Volumetric) |

| Key Absorbing Phase | Magnetite (Fe3O4) |

| Heating Speed | Targets 600 °C within 5 to 7 minutes |

| Chemical Change | Sphalerite (ZnS) to Zincite (ZnO) |

| Physical Impact | Formation of micro-cracks and increased porosity |

| Process Benefit | Enhanced sulfuric acid leaching & reduced residence time |

Revolutionize Your Mineral Processing with KINTEK

Maximize your extraction efficiency and slash processing times with KINTEK’s advanced high-temperature solutions. Backed by expert R&D and world-class manufacturing, KINTEK provides high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems, all fully customizable to meet the unique dielectric heating requirements of your feedstock.

Whether you are treating zinc clinker or developing next-generation refractory materials, our precision lab furnaces deliver the thermal control you need for superior phase transformation and structural optimization.

Ready to upgrade your lab’s capabilities? Contact our experts today to find the perfect customizable furnace for your specific needs.

Visual Guide

References

- Bagdaulet Kenzhaliyev, Symbat Tugambay. Microwave Pre-Treatment for Efficient Zinc Recovery via Acid Leaching. DOI: 10.3390/ma18112496

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Cylindrical Resonator MPCVD Machine System for Lab Diamond Growth

- Vacuum Heat Treat Sintering and Brazing Furnace

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

People Also Ask

- What is the function of a 1% CO-99% Argon gas mixture? Protect Phase Equilibrium Experiments from Oxidation

- Why is a standard constant temperature and humidity curing box used for magnesium slag mortar? Key Pre-treatment Facts

- Why must nickel-based bimetallic catalyst precursors be treated in a blast drying oven? Prevent Structural Failure

- Why is precise temperature control essential for aluminum alloy solidification? Unlock Superior Material Strength

- What is the role of a sealed heating reactor in MSNs synthesis? Master Precision Pore Uniformity

- What is the function of a high-temperature heating reactor in OPF delignification? Unlock High-Purity Cellulose

- Why is the water quenching process necessary for high-entropy alloys? Master Phase Purity and Microstructural Integrity

- What role does an RTA system play in Zirconia preparation? Master Phase Transformation for Advanced Deposition