The final drying step is a critical stabilization phase that transforms acid impregnation from a temporary coating into a permanent structural modification. It serves two essential functions: strictly removing moisture to prevent dangerous downstream reactions and thermally anchoring chemical functional groups to the adsorbent's surface. Without this heat treatment, the material remains chemically unstable and unsuitable for industrial use.

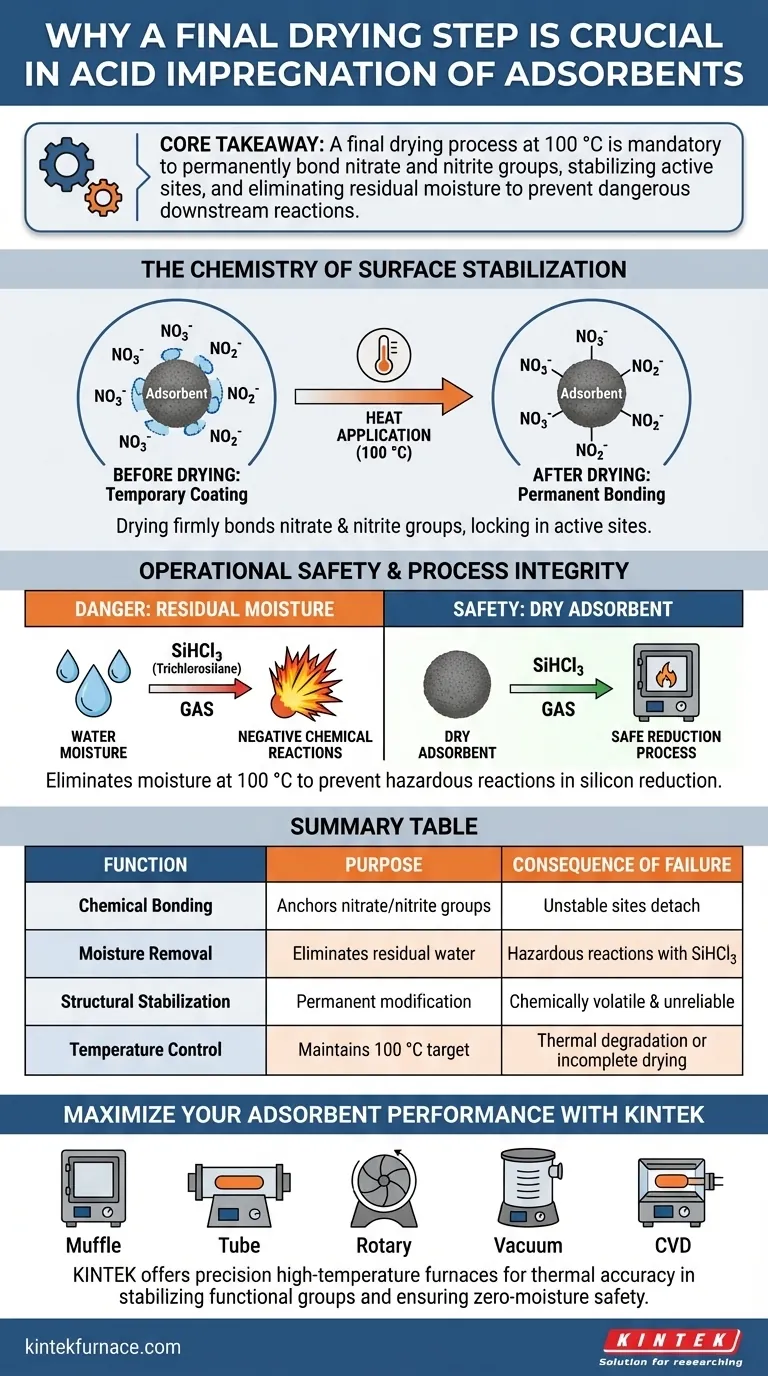

Core Takeaway A final drying process at 100 °C is mandatory to permanently bond nitrate and nitrite groups to the adsorbent, stabilizing its active sites. Crucially, this step eliminates residual moisture that would otherwise trigger detrimental chemical reactions with sensitive industrial gases like trichlorosilane (SiHCl3).

The Chemistry of Surface Stabilization

Bonding Functional Groups

Acid impregnation introduces specific chemical markers, specifically nitrate (NO3−) and nitrite (NO2−) functional groups.

However, simply soaking the material is not enough to attach these groups permanently.

Locking in Active Sites

The application of heat drives the chemical bonding process.

Drying ensures these functional groups are firmly bonded to the adsorbent surface, effectively stabilizing the active sites created during the modification.

Operational Safety and Process Integrity

Eliminating Residual Moisture

The most immediate operational goal of this step is the removal of excess water content.

This drying process is typically executed at 100 °C to ensure thorough evaporation.

Preventing Dangerous Side Reactions

This step is vital for safety in specific industrial contexts, such as silicon reduction furnaces.

These environments often utilize gases like SiHCl3 (trichlorosilane).

If residual moisture remains in the adsorbent, it will trigger negative chemical reactions with the SiHCl3 gas, potentially compromising the entire reduction process.

Understanding the Trade-offs

Precision in Temperature Control

While drying is essential, the temperature parameters must be strictly adhered to.

The process relies on a target of 100 °C to remove water without degrading the newly introduced functional groups.

Deviating significantly from this temperature could result in incomplete bonding or the thermal degradation of the adsorbent's porous structure.

Optimizing Your Restructuring Process

To ensure the success of your acid impregnation technique, align your quality control checks with your specific performance goals.

- If your primary focus is material stability: Verify that the drying duration is sufficient to fully bond the nitrate and nitrite groups, preventing them from detaching during operation.

- If your primary focus is process safety: Implement strict moisture content verification to ensure zero reactivity with SiHCl3 gas before the adsorbent enters the furnace.

Proper drying transforms a volatile chemical mixture into a robust, high-performance tool ready for demanding industrial environments.

Summary Table:

| Function | Purpose | Consequence of Failure |

|---|---|---|

| Chemical Bonding | Anchors nitrate/nitrite groups to the surface | Active sites remain unstable and detach during use |

| Moisture Removal | Eliminates residual water content | Triggers hazardous reactions with gases like SiHCl3 |

| Structural Stabilization | Transforms temporary coating into permanent modification | Material remains chemically volatile and unreliable |

| Temperature Control | Maintains target 100 °C threshold | Thermal degradation of porous structure or incomplete drying |

Maximize Your Adsorbent Performance with KINTEK

Precision heat treatment is the difference between a volatile mixture and a high-performance industrial tool. Backed by expert R&D and manufacturing, KINTEK offers a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, all fully customizable to meet your unique chemical restructuring needs. Whether you are stabilizing functional groups or ensuring zero-moisture safety for silicon reduction processes, our laboratory high-temperature furnaces provide the thermal accuracy your research demands.

Ready to optimize your drying and impregnation protocols? Contact us today to find your custom furnace solution!

Visual Guide

References

- Zhiyuan Liu, Guoqiang Huang. Acid-modified Cu–Ce/HZSM-5 adsorbent removes trace phosphorus impurities from recycled hydrogen during polysilicon production. DOI: 10.1039/d5ra01322d

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What role does a precision mass loss measurement system play? Identifying Vapor Pressure in High-Temp Furnaces

- What is the primary purpose of the 600°C annealing treatment? Optimize Silver-Coated Ceramic Performance

- Why is a rapid cooling process necessary for BZSM nanophosphors? Secrets of Metastable Phase Retention

- How does the thermal treatment enhance the mechanical properties of AZO and ZnO coatings? Boost Durability & Hardness

- What is the primary function of an industrial-grade electric oven for concrete? Optimize High-Temp Material Testing

- What are the drawbacks of cold compacting and sintering? Higher Porosity and Weaker Mechanical Properties

- Why is precise heating rate control necessary? Master Activated Carbon Heat Treatment with KINTEK

- What are the key differences between batch and continuous processing furnaces? Optimize Your Thermal Processing Strategy