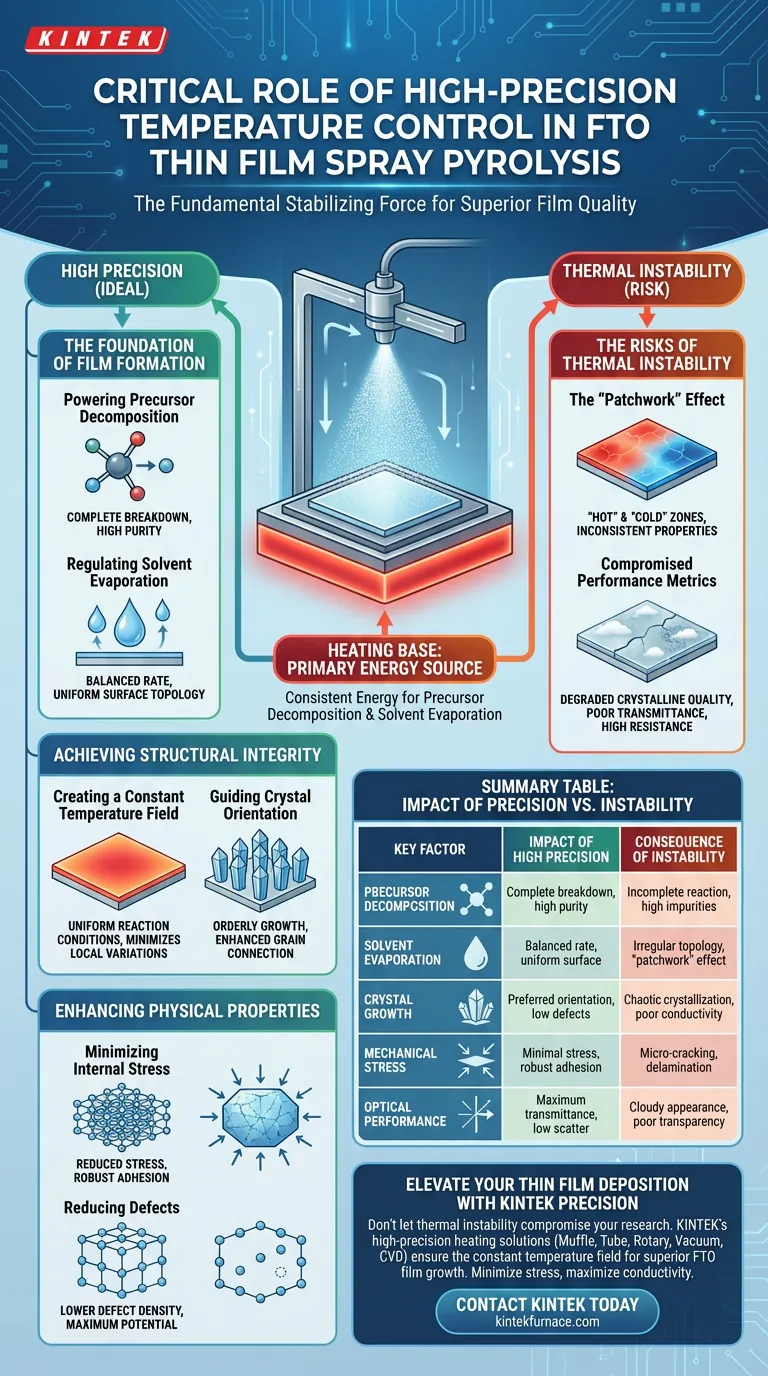

High-precision temperature control is the fundamental stabilizing force in the spray pyrolysis process for FTO thin films. It provides the consistent energy required for proper precursor decomposition and regulates solvent evaporation, ensuring the film forms with the necessary structural integrity. Without this exact thermal management, the chemical reactions become unpredictable, compromising the final material.

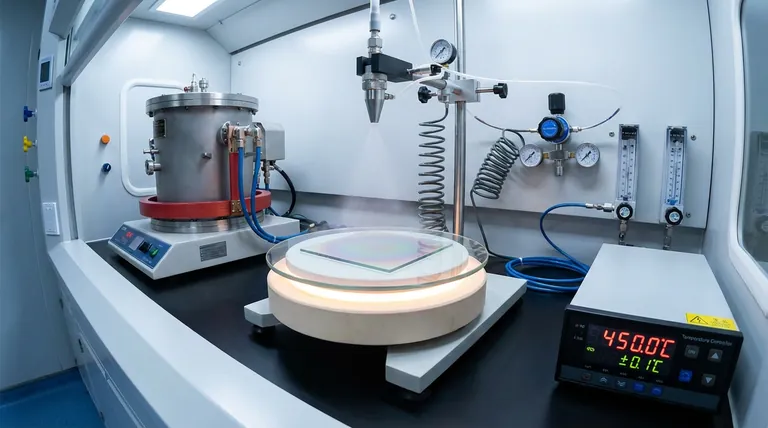

The heating base dictates the energy landscape for the entire deposition process. Precise thermal control ensures a constant temperature field that minimizes internal stresses and defects, directly resulting in superior optical transmittance and electrical conductivity.

The Foundation of Film Formation

Powering Precursor Decomposition

The heating base serves as the primary energy source for the entire chemical process. It provides the heat necessary to break down (decompose) the precursor molecules effectively.

If the temperature is insufficient or fluctuating, the decomposition becomes incomplete. This leads to impurities remaining within the film structure.

Regulating Solvent Evaporation

Temperature stability directly dictates the solvent evaporation rate. This rate must be perfectly balanced to ensure the film settles correctly on the substrate.

Precise control prevents the solvent from evaporating too violently or too slowly. This balance is critical for achieving a smooth, uniform surface topology.

Achieving Structural Integrity

Creating a Constant Temperature Field

High-precision control maintains a constant temperature field across the entire surface of the substrate. This uniformity ensures that every part of the film experiences the same reaction conditions.

When the thermal environment is uniform, precursor molecules undergo ideal chemical reactions. This prevents localized variations that can weaken the film's overall structure.

Guiding Crystal Orientation

A stable thermal environment encourages the film to grow along specific crystal orientations. This orderly growth is preferable to random, chaotic crystallization.

Controlled orientation enhances the connection between grains. This structural alignment is the physical basis for the film's high performance.

Enhancing Physical Properties

Minimizing Internal Stress

Thermal fluctuations during deposition create expansion and contraction disparities. By maintaining high precision, you significantly reduce internal stresses within the material.

Lower stress levels prevent micro-cracking and delamination. This ensures the film remains mechanically robust and adhered to the substrate.

Reducing Defects

A stable heating process drastically lowers the density of defects within the crystal lattice. Defects act as barriers to electron flow and scatter incoming light.

By minimizing these imperfections, the film achieves its maximum potential. This is observed specifically in improved initial optical transmittance and electrical conductivity.

The Risks of Thermal Instability

The "Patchwork" Effect

Without precision control, the substrate develops "hot" and "cold" zones. This results in a film with inconsistent properties across its surface.

One area might be highly conductive while an adjacent area is resistive. This lack of uniformity renders the FTO film unreliable for electronic applications.

Compromised Performance Metrics

If the temperature drifts, the crystalline quality degrades immediately. This leads to a cloudy appearance (poor transmittance) and high resistance.

You cannot compensate for poor thermal control with better chemical precursors. The thermal baseline is the limiting factor for performance.

Making the Right Choice for Your Goal

To maximize the quality of your FTO thin films, consider how temperature precision aligns with your specific objectives:

- If your primary focus is Optical Transmittance: Prioritize thermal stability to minimize defects that scatter light, ensuring the clearest possible film.

- If your primary focus is Electrical Conductivity: Focus on maintaining a constant temperature field to promote specific crystal orientation and reduce electron-scattering grain boundaries.

- If your primary focus is Structural Durability: Ensure precise control to minimize internal stresses, preventing cracking or peeling during subsequent processing.

Ultimately, investing in high-precision temperature regulation is the single most effective way to guarantee the reliability and efficiency of your spray pyrolysis deposition.

Summary Table:

| Key Factor | Impact of High Precision | Consequence of Instability |

|---|---|---|

| Precursor Decomposition | Complete breakdown, high purity | Incomplete reaction, high impurities |

| Solvent Evaporation | Balanced rate, uniform surface | Irregular topology, "patchwork" effect |

| Crystal Growth | Preferred orientation, low defects | Chaotic crystallization, poor conductivity |

| Mechanical Stress | Minimal stress, robust adhesion | Micro-cracking, delamination |

| Optical Performance | Maximum transmittance, low scatter | Cloudy appearance, poor transparency |

Elevate Your Thin Film Deposition with KINTEK Precision

Don't let thermal instability compromise your research or production. KINTEK’s high-precision heating solutions are engineered to provide the constant temperature field necessary for superior FTO film growth.

Backed by expert R&D and manufacturing, we offer Muffle, Tube, Rotary, Vacuum, and CVD systems, along with specialized lab high-temp furnaces—all fully customizable to meet your unique thin-film deposition needs. Our equipment ensures minimal internal stress and maximum electrical conductivity for your materials.

Ready to achieve high-performance FTO thin films?

Contact KINTEK today to discuss your custom thermal solution!

Visual Guide

References

- Paweł Lejwoda, Maciej Thomas. Recovery of Cerium Salts from Sewage Sludge Resulting from the Coagulation of Brewery Wastewater with Recycled Cerium Coagulant. DOI: 10.3390/ma17040938

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

People Also Ask

- What is the significance of using a vacuum drying oven? Optimize Supercapacitor Electrode Performance

- What is the maximum temperature capability of the furnace? Find Your Perfect High-Temp Solution

- Why must temperature loss be monitored during the aluminum alloy refining cycle? Essential Tips for Casting Success

- Why is pressure molding and high-temperature sintering required for UO2-ZrO2? Mastering Material Density

- What are the key requirements for steel materials in high-speed rail, nuclear power, and aerospace industries? Unlock High-Performance Steel Solutions

- How do laboratory tablet presses ensure performance in iodine battery prototypes? Optimize Interfacial Contact Today

- What is the role of a precision annealing furnace in the preparation of ZnO or CuO doped phosphate glass?

- Why is 500°C thermal stabilization necessary for titania supports? Ensure Catalyst Stability and Performance