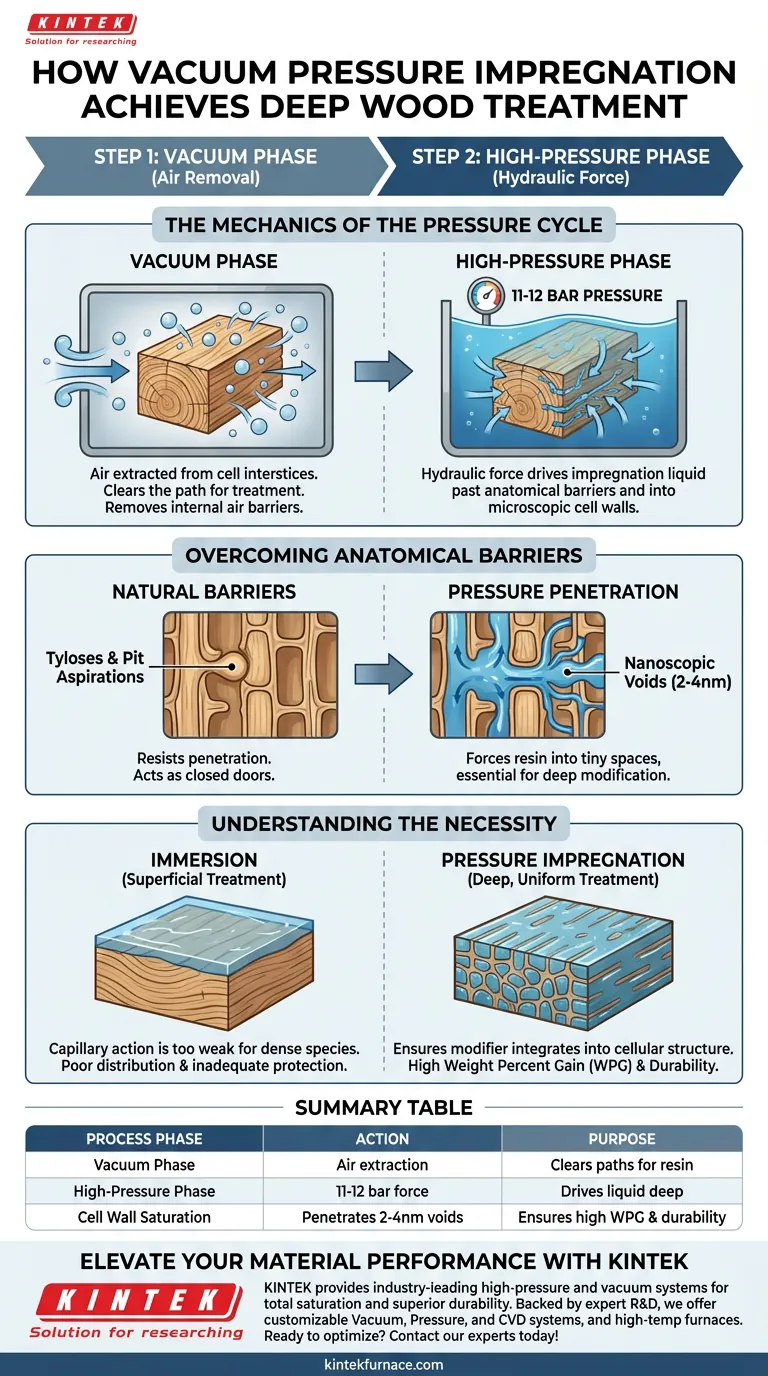

A vacuum pressure impregnation tank achieves deep treatment by utilizing a distinct two-step physical cycle of air removal followed by hydraulic force. Initially, a vacuum extracts air from the wood's internal structure, effectively clearing the path for treatment. Subsequently, high pressure—typically ranging from 11 to 12 bar—forces the impregnation liquid past anatomical barriers and into the microscopic cell walls, ensuring thorough saturation.

By mechanically overcoming the natural anatomical resistance of wood, vacuum pressure impregnation ensures resin penetrates not just the surface, but the microscopic cell walls. This process is the physical prerequisite for achieving significant weight percent gain (WPG) and lasting durability in low-permeability species.

The Mechanics of the Pressure Cycle

The Vacuum Phase

The first step in the process is the application of a vacuum. This removes air trapped within the wood's structure, specifically from the cell interstices.

If this air were not removed, it would act as a barrier, preventing the impregnation liquid from occupying the space inside the wood.

The High-Pressure Phase

Once the air is evacuated, the system applies high pressure to the impregnation liquid.

References indicate that pressures of approximately 11 to 12 bar are required. This provides the mechanical force necessary to drive the resin solution into the cell lumens and walls.

Overcoming Anatomical Barriers

Bypassing Internal Blockages

Wood naturally resists liquid penetration due to anatomical features like tyloses and pit aspirations.

These features act as closed doors within the wood's plumbing system. The high pressure generated by the tank forces resin molecules to physically overcome these barriers, ensuring the liquid reaches deep into the material.

Penetrating Nanoscopic Voids

The voids within a wood cell wall are incredibly small, measuring as little as 2-4 nm in species like Scots pine.

Simple atmospheric immersion (soaking) generates insufficient force to enter these micropores. The pressure tank provides the energy needed to inject resin into these tiny spaces, which is essential for deep modification.

Understanding the Necessity

Why Immersion is Insufficient

Atmospheric immersion relies on capillary action, which is too weak to penetrate dense or impermeable wood species effectively.

Without the mechanical drive of the pressure tank, treatment remains superficial. This leads to poor distribution of the modifier and inadequate protection.

The Role of Density

For wood species with high density or poor natural permeability, this equipment is the only way to achieve uniform distribution.

It ensures that the modifier is not just coating the outside, but is integrated into the cellular structure of the wood.

Making the Right Choice for Your Goal

To maximize the effectiveness of your wood modification process, consider the following applications:

- If your primary focus is processing dense timber: You must utilize high pressure (12 bar) to force resin past anatomical barriers like pit aspirations and tyloses.

- If your primary focus is maximum durability: Rely on the vacuum-pressure cycle to fill nanoscopic cell wall voids, as this is the prerequisite for high weight percent gain (WPG) and superior water resistance.

Mastering the vacuum-pressure cycle allows you to transform even naturally resistant timber into a high-performance modified material.

Summary Table:

| Process Phase | Action Taken | Purpose in Wood Modification |

|---|---|---|

| Vacuum Phase | Air extraction from cell interstices | Removes internal air barriers to clear paths for resin |

| High-Pressure Phase | 11-12 bar hydraulic force | Overcomes tyloses and pit aspirations to drive liquid deep |

| Cell Wall Saturation | Penetration of 2-4nm voids | Ensures high Weight Percent Gain (WPG) and durability |

| Structural Integration | Microscopic resin injection | Transforms low-permeability species into high-performance timber |

Elevate Your Material Performance with KINTEK

Don't let natural anatomical barriers limit your wood modification results. KINTEK provides industry-leading high-pressure and vacuum systems designed to achieve total saturation and superior durability in even the densest timber species.

Backed by expert R&D and manufacturing, KINTEK offers Vacuum, Pressure, and CVD systems, along with a full range of lab high-temp furnaces—all fully customizable to meet your unique processing needs. Whether you are scaling up production or conducting precision research, our equipment ensures the deep treatment required for high-performance results.

Ready to optimize your impregnation process? Contact our experts today to find the perfect system for your lab or facility!

Visual Guide

References

- Johannes Karthäuser, Holger Militz. Utilizing pyrolysis cleavage products from softwood kraft lignin as a substitute for phenol in phenol-formaldehyde resins for modifying different wood species. DOI: 10.1007/s00107-024-02056-4

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What are the key considerations when choosing a continuous furnace? Optimize Your High-Volume Production

- How is a laboratory oven utilized during the impregnation stage of APC preparation? Optimize Biochar Activation

- What is the primary role of an industrial-grade oven in the preparation of chitosan-modified soil samples?

- Why is precise sample loading critical in CO2 capture experiments? Avoid Bed Effects and Ensure Data Integrity

- What is the purpose of magnetron sputtering in N-I-P CsPbBr3 detectors? Optimize Charge Transport & Stability

- Why are reactive polyurethane systems a focus of thermal analysis in leather finishing? Balance Safety and Aesthetics

- How does a constant temperature heating device influence rare earth leaching? Boost Extraction Efficiency to 95.72%

- What is induction heating and what materials can it be used on? A Guide to Fast, Precise Heating