The enhancement of coke strength is essential because it guarantees the physical stability and permeability of the material column inside the blast furnace. In high-temperature and high-pressure environments, strong coke resists pulverization, maintaining the critical gas flow required for efficient chemical reduction. Without this mechanical integrity, the furnace's operation becomes unstable, hindering both cost efficiency and low-carbon objectives.

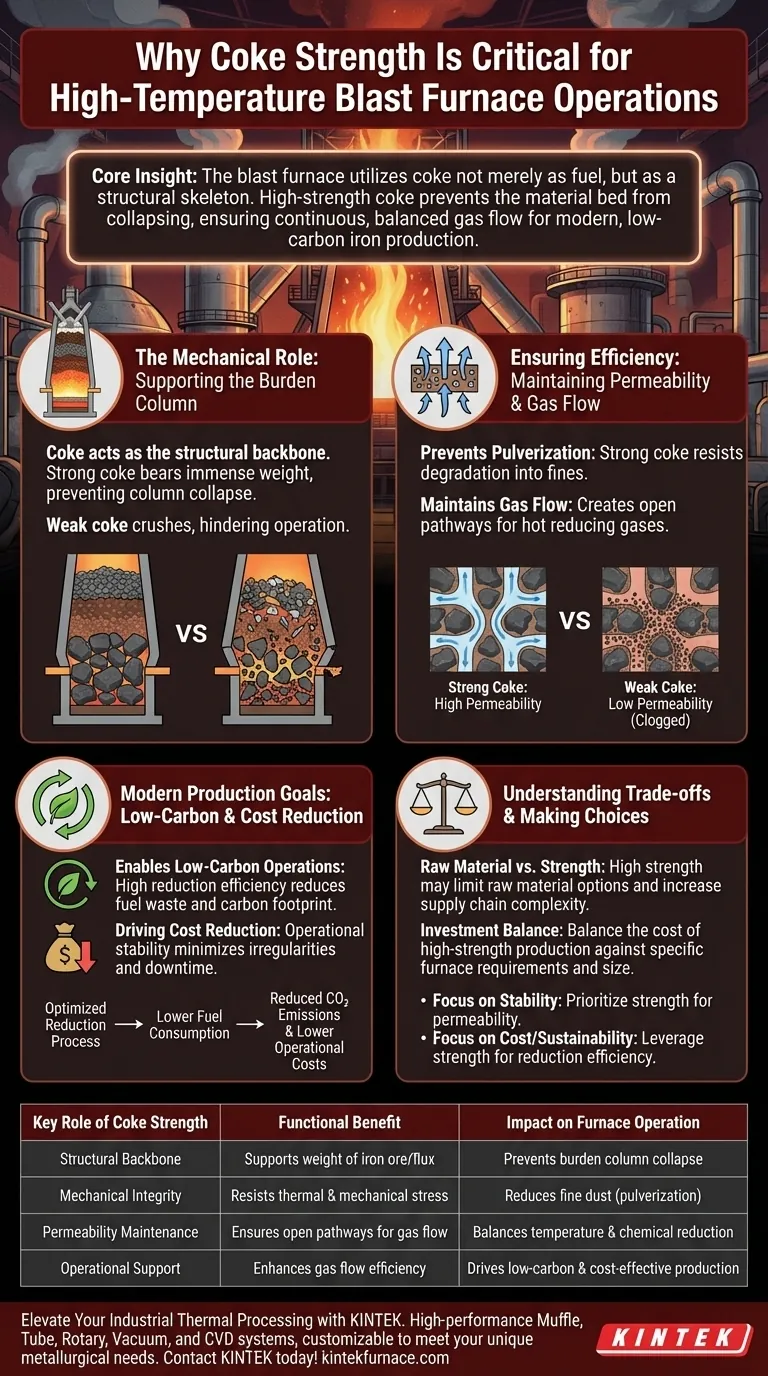

Core Insight: The blast furnace utilizes coke not merely as fuel, but as a structural skeleton. High-strength coke prevents the material bed from collapsing into dust, ensuring the continuous, balanced gas flow necessary for modern, low-carbon iron production.

The Mechanical Role of Coke in the Furnace

Supporting the Burden Column

The blast furnace acts as a massive reaction vessel where solids move down and gases move up. Coke must act as the structural backbone of this system.

It bears the immense weight of the iron ore and flux layers above it. If the coke lacks sufficient strength, it will crush under this load, leading to a collapse of the material column.

Resisting Thermal and Mechanical Stress

Conditions inside the furnace involve extreme heat and pressure. Specific equipment and processes are employed to enhance coke strength so it can withstand this hostile environment.

High-strength coke maintains its shape and form even when subjected to intense thermal shock and mechanical abrasion. This resistance is the primary defense against operational instability.

Ensuring Operational Efficiency

Preventing Pulverization

The primary risk of weak coke is pulverization. When coke degrades into fine dust (fines), it fills the voids between the larger solid materials.

High-strength coke does not easily break down. By remaining intact, it prevents these fines from clogging the furnace, which would otherwise choke the system and halt production.

Maintaining Gas Flow and Permeability

For the furnace to function, hot reducing gases must ascend freely through the burden. Strong coke creates and preserves the necessary permeability (open pathways) for this gas.

This ensures a gas flow balance throughout the furnace. Consistent gas distribution allows for uniform temperature and chemical reactions, optimizing the reduction efficiency of the iron ore.

The Link to Modern Production Goals

Enabling Low-Carbon Operations

Efficiency in gas flow translates directly to environmental performance. By maintaining high reduction efficiency, strong coke provides the hardware support needed for low-carbon blast furnace operations.

When the reduction process is optimized, less fuel is wasted, and the carbon footprint of the operation is minimized.

Driving Cost Reduction

Operational stability is key to economic performance. The enhancement of coke strength reduces the frequency of irregularities and potential downtime caused by poor permeability.

By ensuring the process runs smoothly and efficiently, high-strength coke directly contributes to overall cost reduction for the facility.

Understanding the Trade-offs

Raw Material Requirements

Achieving high strength often dictates the selection of specific coal blends or processing methods.

While essential for furnace performance, prioritizing maximum strength may limit the range of usable raw materials, potentially increasing the complexity of the supply chain.

The Balance of Investment

Implementing the specific equipment and processes required to increase coke strength represents an operational investment.

Operators must balance the cost of producing ultra-high-strength coke against the specific requirements of their blast furnace size. The goal is to achieve sufficient integrity to prevent pulverization without over-engineering the material beyond what the furnace demands.

Making the Right Choice for Your Goal

To optimize blast furnace operations, you must view coke strength as a functional prerequisite for stability.

- If your primary focus is Operational Stability: Prioritize coke strength to prevent pulverization and maintain maximum permeability in the material column.

- If your primary focus is Cost and Sustainability: Leverage high-strength coke to maximize reduction efficiency, thereby lowering fuel consumption and carbon emissions.

Ultimately, maintaining coke integrity is the foundational requirement for sustaining efficient, low-cost, and low-carbon iron production.

Summary Table:

| Key Role of Coke Strength | Functional Benefit | Impact on Furnace Operation |

|---|---|---|

| Structural Backbone | Supports weight of iron ore/flux | Prevents burden column collapse |

| Mechanical Integrity | Resists thermal & mechanical stress | Reduces fine dust (pulverization) |

| Permeability Maintenance | Ensures open pathways for gas flow | Balances temperature & chemical reduction |

| Operational Support | Enhances gas flow efficiency | Drives low-carbon & cost-effective production |

Elevate Your Industrial Thermal Processing with KINTEK

Maintaining material integrity under extreme conditions is non-negotiable for operational success. Backed by expert R&D and manufacturing, KINTEK offers high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems, along with other specialized lab high-temperature furnaces—all fully customizable to meet your unique metallurgical and research needs.

Whether you are testing material strength or optimizing chemical reduction processes, our precision equipment provides the hardware support necessary for stability and cost reduction. Contact KINTEK today to discuss your custom solution!

Visual Guide

References

- The Technical Society, The Iron and Steel Institute of Japan. Production and Technology of Iron and Steel in Japan during 2024. DOI: 10.2355/isijinternational.65.7app_i

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- Why is temperature control precision critical for a sample heating furnace? Master Ti-V-Cr Alloy Oxidation Kinetics

- What is the primary design purpose of industrial electric furnaces for SA-178 Gr A steel? Ensure Pipe End Reliability

- What gas is used in a graphite furnace? A Guide to Argon vs. Nitrogen for Optimal Analysis

- What is the role of vacuum pressure impregnation equipment in Fe3O4 synthesis? Master Magnetic Wood Fiber Engineering

- How does a high-sensitivity non-contact microphone assist in detecting cracks during the solidification of molten slag?

- What industries commonly use batch furnaces? Essential for Aerospace, Medical, and Electronics

- What is the function of PVA binder and high-pressure compression in SSBSN? Optimize Your Ceramic Green Body Preparation

- Why is an in-situ XRD system with a high-temperature furnace necessary for Y-W-N ceramics? Capture Real-Time Stability