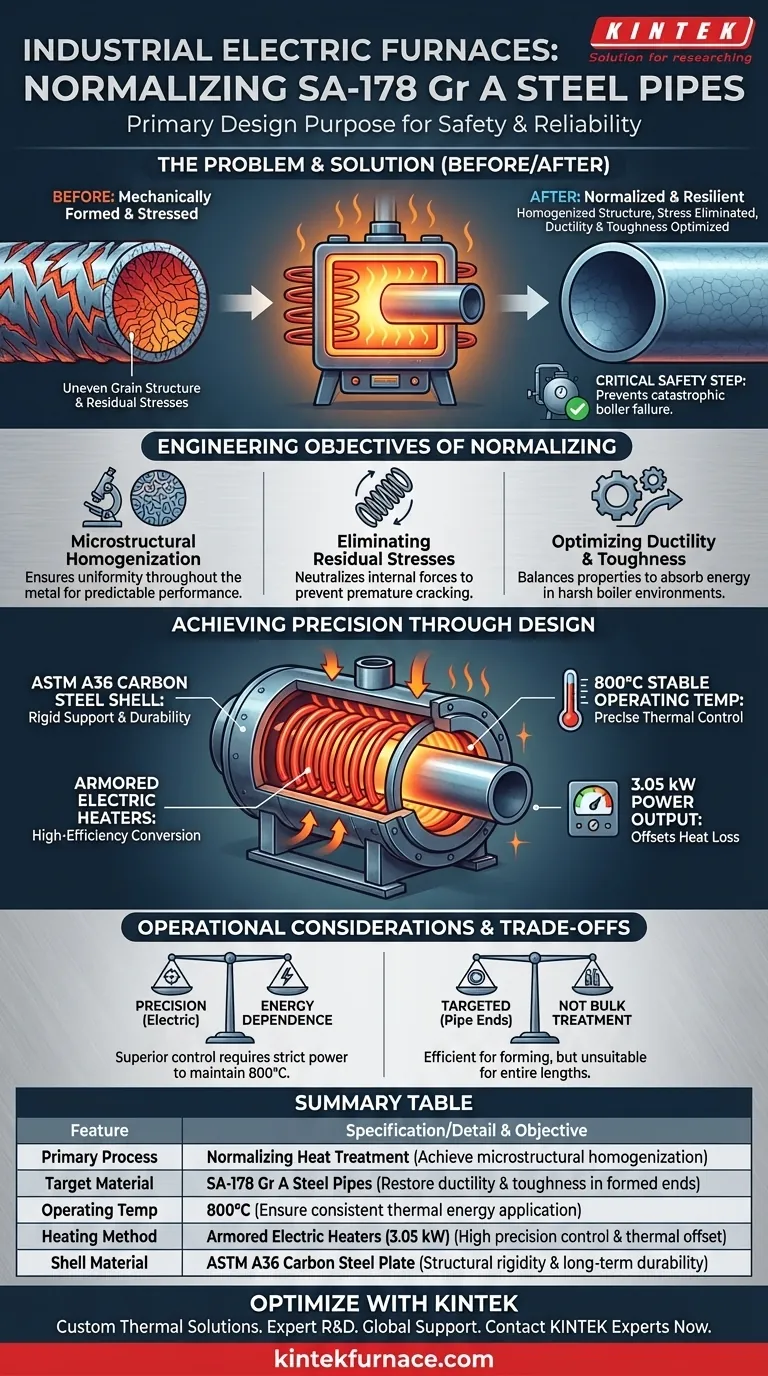

The primary design purpose of these industrial electric furnaces is to perform normalizing heat treatment specifically on the mechanically formed ends of SA-178 Gr A steel pipes. This equipment is engineered to apply precise thermal energy to achieve microstructural homogenization and eliminate the residual stresses caused by mechanical shaping.

By restoring the material's internal structure, the furnace ensures the pipe ends possess the necessary ductility and toughness. This is a critical safety step designed to prevent catastrophic failure during high-pressure industrial boiler operations.

The Engineering Objectives of Normalizing

The heat treatment process is not merely about reaching a temperature; it is about reversing the effects of mechanical deformation. The furnace is the tool used to reset the steel's physical properties.

Microstructural Homogenization

When SA-178 Gr A pipes are mechanically formed, their internal grain structure can become uneven. The furnace provides a controlled environment to homogenize this microstructure, ensuring uniformity throughout the metal. This uniformity is essential for predictable performance under stress.

Eliminating Residual Stresses

Mechanical forming introduces significant internal tension, known as residual stress. If left untreated, these stresses create weak points susceptible to cracking. The furnace heats the pipe ends to relax these internal forces, effectively neutralizing the risk of premature failure.

Optimizing Ductility and Toughness

The ultimate metallurgical goal is balancing the steel's properties. By normalizing the steel, the furnace optimizes both ductility (the ability to deform without breaking) and toughness (the ability to absorb energy). This makes the pipes resilient enough for the harsh environment of an industrial boiler.

Achieving Precision Through Design

To achieve the metallurgical goals above, the furnace requires a design focused on thermal stability and structural rigidity.

Precision Thermal Control

Unlike gas-based systems, these electric furnaces utilize armored electric heaters. These components convert electrical energy into thermal energy with high efficiency, capable of maintaining a stable operating temperature of 800°C.

Combating Heat Loss

The heating elements are calibrated with specific power outputs (e.g., 3.05 kW) to actively offset heat losses. This ensures the constant high-temperature environment required for consistent normalization is never compromised.

Structural Stability with ASTM A36

The furnace's external shell is constructed from ASTM A36 carbon steel plate. This material is selected for its high cost-effectiveness and excellent weldability, providing a rigid support frame that maintains structural integrity despite the intense internal heat.

Operational Considerations and Trade-offs

While electric furnaces offer superior control, understanding their limitations is vital for efficient operation.

Energy Dependence vs. Precision

Electric heating offers higher thermal control precision than gas systems, which is critical for normalizing. However, this comes at the cost of strict electrical power requirements to maintain the 3.05 kW output needed to offset thermal losses.

Targeted vs. Bulk Treatment

These furnaces are explicitly designed for treating the ends of pipes. This specialized focus makes them highly efficient for joining or forming applications but renders them unsuitable for bulk heat treatment of entire pipe lengths without modification.

Making the Right Choice for Your Goal

The selection of this equipment should be driven by your specific manufacturing requirements regarding precision and safety.

- If your primary focus is process reliability: Prioritize the use of armored electric heaters over gas systems to ensure the strict temperature stability (800°C) required for normalizing.

- If your primary focus is equipment longevity: Ensure the external structure utilizes ASTM A36 carbon steel to guarantee mechanical strength and weldability over long-term industrial use.

- If your primary focus is component safety: verify that the heat treatment specifically targets the mechanically formed ends to eliminate the residual stresses that lead to boiler failure.

Ultimately, the value of this furnace lies in its ability to transform a mechanically stressed pipe component into a reliable, safety-critical element of a boiler system.

Summary Table:

| Feature | Specification/Detail | Engineering Objective |

|---|---|---|

| Primary Process | Normalizing Heat Treatment | Achieve microstructural homogenization |

| Target Material | SA-178 Gr A Steel Pipes | Restore ductility and toughness in formed ends |

| Operating Temp | 800°C (Stable Environment) | Ensure consistent thermal energy application |

| Heating Method | Armored Electric Heaters (3.05 kW) | High precision control and thermal offset |

| Shell Material | ASTM A36 Carbon Steel Plate | Structural rigidity and long-term durability |

Optimize Your Industrial Heat Treatment with KINTEK

Don't compromise on the safety of your high-pressure components. KINTEK provides industry-leading thermal solutions backed by expert R&D and precision manufacturing. Whether you require Muffle, Tube, Rotary, Vacuum, or CVD systems, our high-temperature furnaces are fully customizable to meet the rigorous normalizing demands of SA-178 Gr A steel and other specialized materials.

Take the next step in process reliability today:

- Expert Consulting: Tailored solutions for pipe end treatment and stress relief.

- Precision Engineering: Systems designed for 800°C+ stability and microstructural uniformity.

- Global Support: Equipment built to ASTM standards for maximum durability.

Visual Guide

References

- Gustavo Ribeiro Zanini, LUIS CARLOS GERON. PROJETO DE UM FORNO ELÉTRICO INDUSTRIAL PARA TRATAMENTO TÉRMICO TUBOS DE AÇO SA-178 GR A. DOI: 10.52138/citec.v17i01.437

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- What is the function of a laboratory oven in ZnO processing? Optimize Precursor Drying & Prevent Agglomeration

- What is the function of a forced air drying oven in the dehydration of acid-washed zeolite? Ensure Sample Purity.

- What are the advantages of using batch furnaces? Boost Your Process Flexibility and Precision

- Why is an auxiliary gas supply device required for oil sludge pyrolysis? Ensure Stable Thermal Balance

- What is the significance of the 200 °C calcination for Fe3O4/biochar? Enhancing Stability and Magnetic Recovery

- What are the advantages of mastering the sintering step? Achieve Cost Savings and Complex Designs

- How does a closed-loop temperature control system contribute to the preparation of Hafnium Carbide via laser pyrolysis?

- Why is Boron Nitride (BN) powder used as a diluent? Enhance Accuracy in Iron Oxidation Kinetics