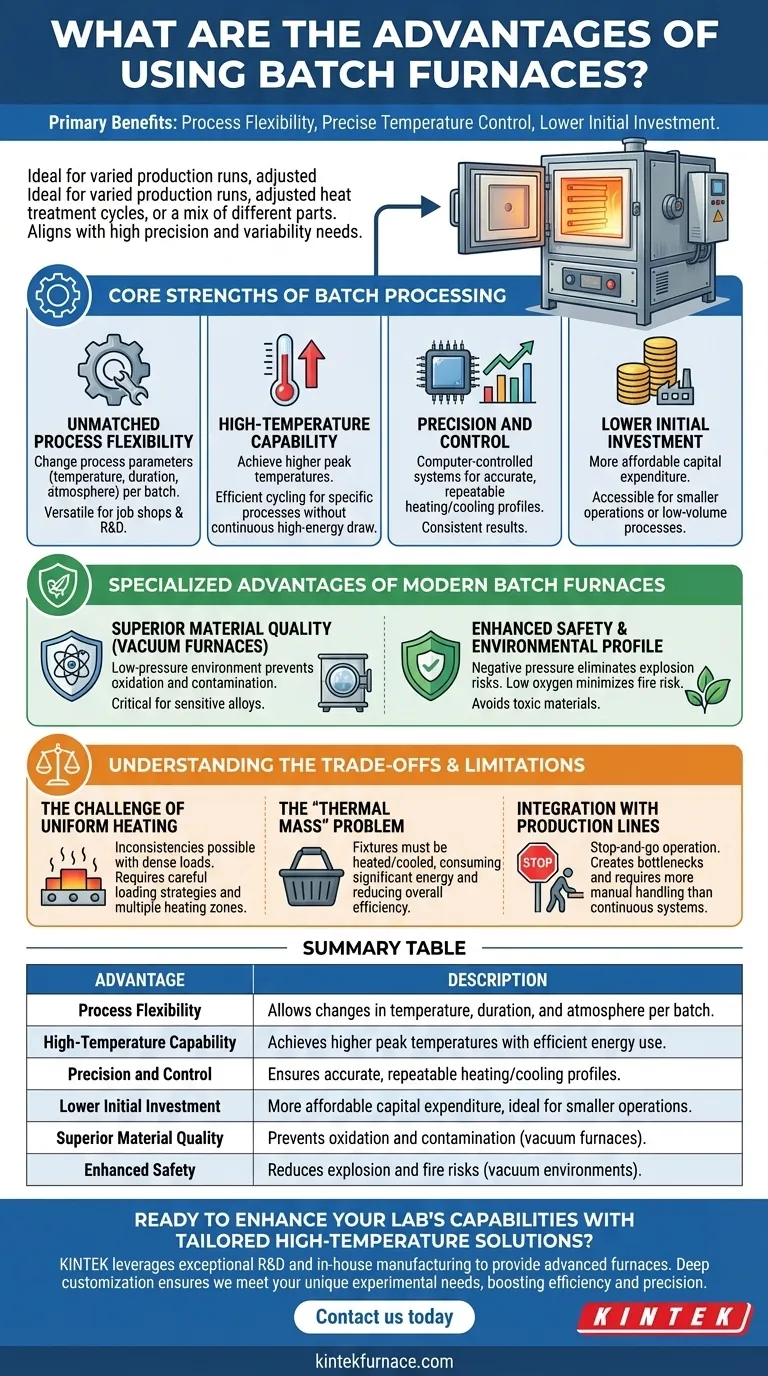

In industrial heating, the primary advantages of a batch furnace are its process flexibility, precise temperature control, and lower initial investment. Unlike continuous furnaces designed for a single, unending process, batch furnaces excel at handling discrete loads. This makes them ideal for applications where production runs are varied, heat treatment cycles need to be adjusted, or a mix of different parts requires processing.

The decision to use a batch furnace is not about its capabilities in isolation, but about aligning its operational model with your specific production needs. It excels in applications demanding high precision and variability over sheer, continuous volume.

The Core Strengths of Batch Processing

Batch furnaces are defined by their method of operation: a single load (a "batch") of parts is loaded, processed through a complete heating and cooling cycle, and then unloaded. This fundamental difference from continuous systems creates several key advantages.

Unmatched Process Flexibility

Because each batch is a self-contained cycle, you can change the process parameters—such as temperature, duration, and atmosphere—for every new load. This makes the furnace exceptionally versatile for job shops, research and development, or facilities that produce a wide variety of products.

High-Temperature Capability

Batch furnaces can often achieve higher peak temperatures than their continuous counterparts. Since they are not maintaining a constant thermal state, they can be designed to cycle up to very high temperatures for specific processes without the immense energy draw of keeping a long continuous chamber at that same temperature.

Precision and Control

Modern batch furnaces, especially specialized types like vacuum or tube furnaces, offer exceptionally precise temperature control. Computer-controlled systems ensure that complex heating and cooling profiles are executed with high accuracy, leading to repeatable and consistent results from one batch to the next.

Lower Initial Investment

For many applications, a batch furnace represents a lower capital expenditure than a large, integrated continuous furnace system. This makes them a more accessible entry point for smaller operations or for specialized, low-volume processes.

Specialized Advantages of Modern Batch Furnaces

Beyond the general benefits, specific types of batch furnaces offer advanced capabilities, particularly in the areas of material quality and safety.

Superior Material Quality (Vacuum Furnaces)

A vacuum furnace is a type of batch furnace that operates in a low-pressure environment. By removing oxygen and other gases, it completely prevents oxidation, contamination, and material degradation during heating. This is critical for processing sensitive alloys and ensuring the highest possible material integrity.

Enhanced Safety and Environmental Profile

Operating at negative pressure, vacuum furnaces eliminate the risk of explosion common to pressurized vessels. The low-oxygen environment also minimizes the risk of fire. Furthermore, modern heat treating in batch furnaces replaces older methods that involved toxic materials like cyanide salts, eliminating land contamination and hazardous waste disposal issues.

Understanding the Trade-offs and Limitations

To make an informed decision, you must weigh the advantages against the inherent operational trade-offs of batch processing.

The Challenge of Uniform Heating

While many designs promote temperature uniformity, the nature of loading a dense batch of parts can create inconsistencies. Parts on the exterior of the load, closer to the heat source, will heat faster than parts in the center. Achieving true uniformity requires careful loading strategies and advanced furnace designs with multiple heating zones.

The "Thermal Mass" Problem

Parts in a batch furnace must be loaded onto fixtures, such as baskets, racks, or carts. These fixtures must be heated and cooled along with the parts, which consumes a significant amount of energy. This added thermal mass can reduce the overall energy efficiency of the process compared to a continuous furnace where the conveyor belt is always hot.

Integration with Production Lines

Batch processing is inherently a stop-and-go operation. Parts must be removed from the main production line, manually grouped and loaded, processed, and then unloaded. This creates bottlenecks and requires more manual handling than an automated continuous furnace, which integrates seamlessly into a high-volume production line.

Choosing the Right Furnace for Your Application

The best choice depends entirely on your operational goals.

- If your primary focus is high-volume, standardized production: A continuous furnace is likely the more efficient choice due to its seamless integration and energy efficiency at scale.

- If your primary focus is process variability and precision: A batch furnace is ideal for handling different materials, complex heat cycles, or for research and development labs.

- If your primary focus is the absolute highest material integrity: A vacuum batch furnace is the definitive solution, as it is the only way to completely eliminate oxidation and surface contamination.

- If your primary focus is minimizing initial capital cost: A standard batch furnace often represents a lower upfront investment and a more versatile starting point than a dedicated continuous system.

Ultimately, selecting the right furnace requires a clear-eyed assessment of your specific process requirements, production volume, and quality standards.

Summary Table:

| Advantage | Description |

|---|---|

| Process Flexibility | Allows changes in temperature, duration, and atmosphere per batch for versatile applications. |

| High-Temperature Capability | Achieves higher peak temperatures with efficient energy use in cycling processes. |

| Precision and Control | Ensures accurate, repeatable heating and cooling profiles for consistent results. |

| Lower Initial Investment | More affordable capital expenditure, ideal for smaller operations or low-volume processes. |

| Superior Material Quality | In vacuum furnaces, prevents oxidation and contamination for high-integrity materials. |

| Enhanced Safety | Reduces explosion and fire risks, especially in vacuum environments with low oxygen. |

Ready to enhance your lab's capabilities with tailored high-temperature solutions? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental needs, boosting efficiency and precision. Contact us today to discuss how our batch furnaces can transform your processes!

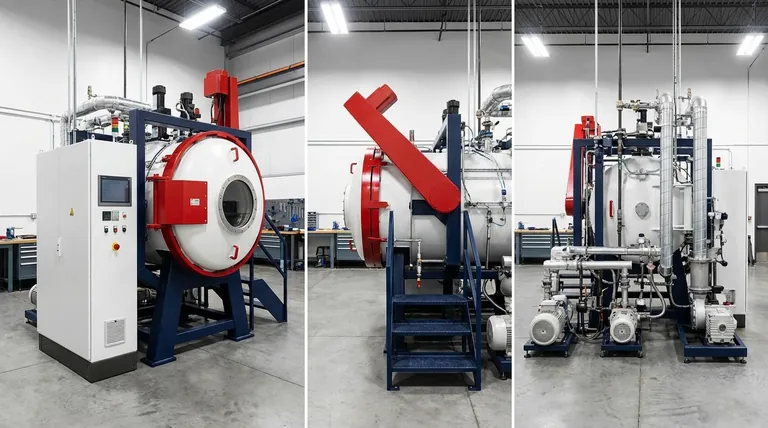

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What role does a vacuum hot pressing furnace play in TiBw/TA15 synthesis? Enhance In-Situ Composite Performance

- Why is a vacuum environment essential for sintering Titanium? Ensure High Purity and Eliminate Brittleness

- Why must sintering equipment maintain a high vacuum for high-entropy carbides? Ensure Phase Purity and Peak Density

- What is the mechanism of a vacuum sintering furnace for AlCoCrFeNi2.1 + Y2O3? Optimize Your High-Entropy Alloy Processing

- How does pressure application in a vacuum hot press furnace facilitate sintering of copper composites? Optimize Density