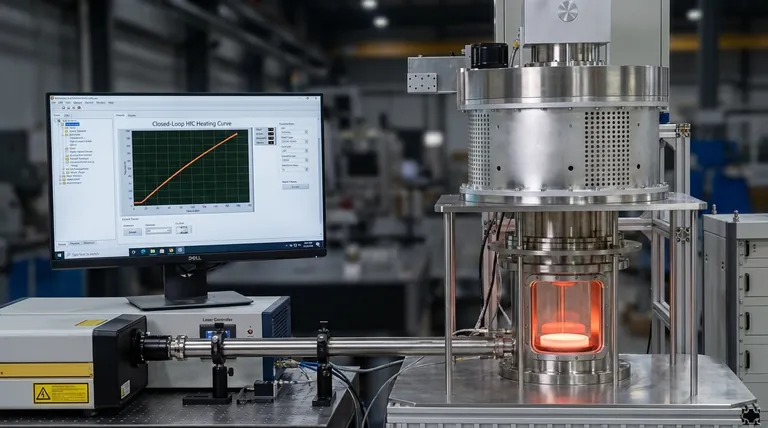

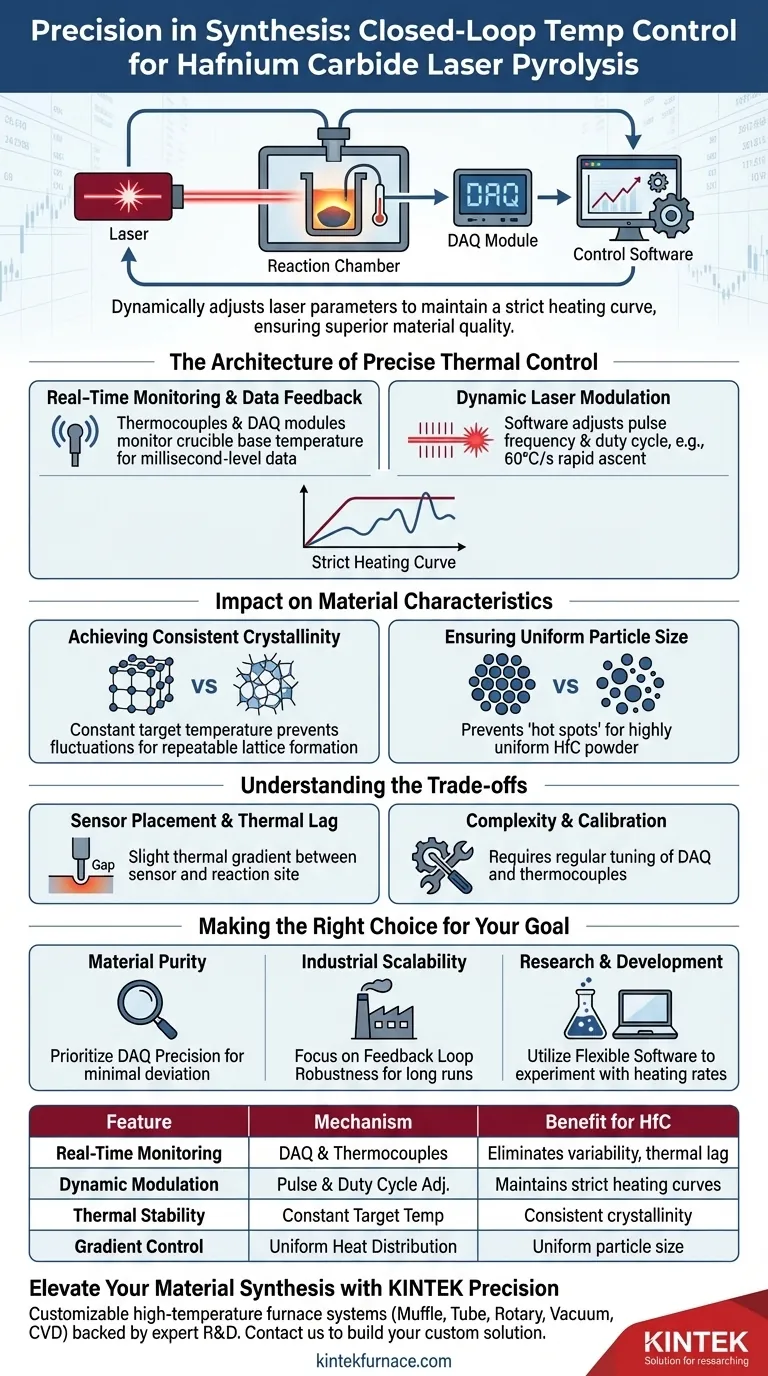

Precise thermal management is the cornerstone of high-purity material synthesis. In the preparation of Hafnium Carbide (HfC) via laser pyrolysis, a closed-loop system maintains the reaction environment by dynamically adjusting laser parameters in response to real-time temperature data. This ensures the material follows a strict heating curve, resulting in superior structural integrity and particle uniformity.

The core value of a closed-loop temperature control system lies in its ability to eliminate process variability by syncing laser output with real-time crucible temperatures. This precision is essential for producing Hafnium Carbide with consistent crystallinity and predictable particle morphology.

The Architecture of Precise Thermal Control

Real-Time Monitoring and Data Feedback

The system utilizes thermocouples integrated with data acquisition (DAQ) modules to monitor the temperature at the base of the crucible. This setup provides a continuous stream of thermal data, allowing the control software to "see" the exact state of the reaction environment at any given millisecond.

Dynamic Laser Modulation

Based on the feedback from the sensors, the software dynamically modulates the laser pulse frequency and duty cycle. This allows the system to force the reaction to follow a specific heating curve, such as a rapid ascent of 60°C per second, which is critical for the kinetics of HfC formation.

Impact on Material Characteristics

Achieving Consistent Crystallinity

By maintaining a constant target temperature throughout the pyrolysis reaction, the system prevents the thermal fluctuations that often plague manual or open-loop setups. This thermal stability ensures that the crystal lattice of the Hafnium Carbide forms correctly and repeatably across different batches.

Ensuring Uniform Particle Size

The closed-loop mechanism prevents the formation of "hot spots" or unintended temperature drops that lead to irregular grain growth. The result is a Hafnium Carbide powder with a highly uniform particle size, which is a prerequisite for advanced ceramic applications.

Understanding the Trade-offs

Sensor Placement and Thermal Lag

While placing thermocouples at the base of the crucible protects the sensors, it creates a slight thermal gradient between the sensor and the actual reaction site. This spatial gap can introduce a minor delay in feedback that must be compensated for via software algorithms.

Complexity and Calibration

Implementing a closed-loop system significantly increases the technical complexity of the laser pyrolysis rig compared to fixed-output systems. Regular calibration of the DAQ modules and thermocouples is mandatory to ensure that the "perceived" temperature aligns with the actual thermal energy being delivered to the precursors.

Making the Right Choice for Your Goal

To successfully implement this system in a laboratory or industrial setting, consider the following priorities:

- If your primary focus is Material Purity: Prioritize the precision of the DAQ modules to ensure the heating curve is followed with minimal deviation.

- If your primary focus is Industrial Scalability: Focus on the robustness of the feedback loop to maintain consistency across long production runs where environmental variables might shift.

- If your primary focus is Research and Development: Utilize the software's ability to easily modify the pulse frequency and duty cycle to experiment with different heating rates beyond the standard 60°C per second.

Through the integration of real-time feedback and dynamic laser adjustment, closed-loop control transforms laser pyrolysis from a variable process into a highly predictable manufacturing science.

Summary Table:

| Feature | Mechanism | Benefit for Hafnium Carbide (HfC) |

|---|---|---|

| Real-Time Monitoring | DAQ modules & thermocouples | Eliminates process variability and thermal lag |

| Dynamic Modulation | Laser pulse & duty cycle adjustment | Maintains strict heating curves (e.g., 60°C/s) |

| Thermal Stability | Constant target temperature | Ensures consistent crystallinity and lattice formation |

| Gradient Control | Uniform heat distribution | Prevents hot spots for highly uniform particle size |

Elevate Your Material Synthesis with KINTEK Precision

Achieving the perfect heating curve for Hafnium Carbide requires hardware that reacts as fast as your science evolves. Backed by expert R&D and manufacturing, KINTEK offers a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, all fully customizable to integrate advanced closed-loop temperature controls.

Whether you are refining HfC particle morphology in a lab or scaling up high-temp ceramic production, our engineering team is ready to design the thermal solution you need. Don't leave your material purity to chance—contact KINTEK today to build your custom high-temperature furnace system.

Visual Guide

References

- Shalini Rajpoot, Chengying Xu. Synthesis of hafnium carbide (HfC) via one‐step selective laser reaction pyrolysis from liquid polymer precursor. DOI: 10.1111/jace.20650

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant Rotating Furnace

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What role does starch play in g-C3N4-Bi2S3 and g-C3N4-ZnS synthesis? Enhance Composite Stability and Dispersion

- Why is the calcination process essential for Fe3O4/CeO2 and NiO/Ni@C? Control Phase Identity and Conductivity

- What effect does a laboratory hot plate have on 2D material heterostructures? Enhancing Interlayer Bonding Quality

- What role does graphite paper play in magnesium vapor condensation experiments? A Key to High-Purity Collection & Analysis

- What are the specific temperature control requirements for alpha-SiC growth? Master the 1700°C Thermal Threshold

- How do precision temperature-controlled ovens function for SiC-Ti3SiC2 preform curing? Expert Thermal Control Guide

- What is the function of the circulation pump in a salt bath furnace? Master Sorbite Transformation Quality

- What are the advantages of combining vacuum hot rolling with small hole vacuuming? High-Bonding Clad Plate Production