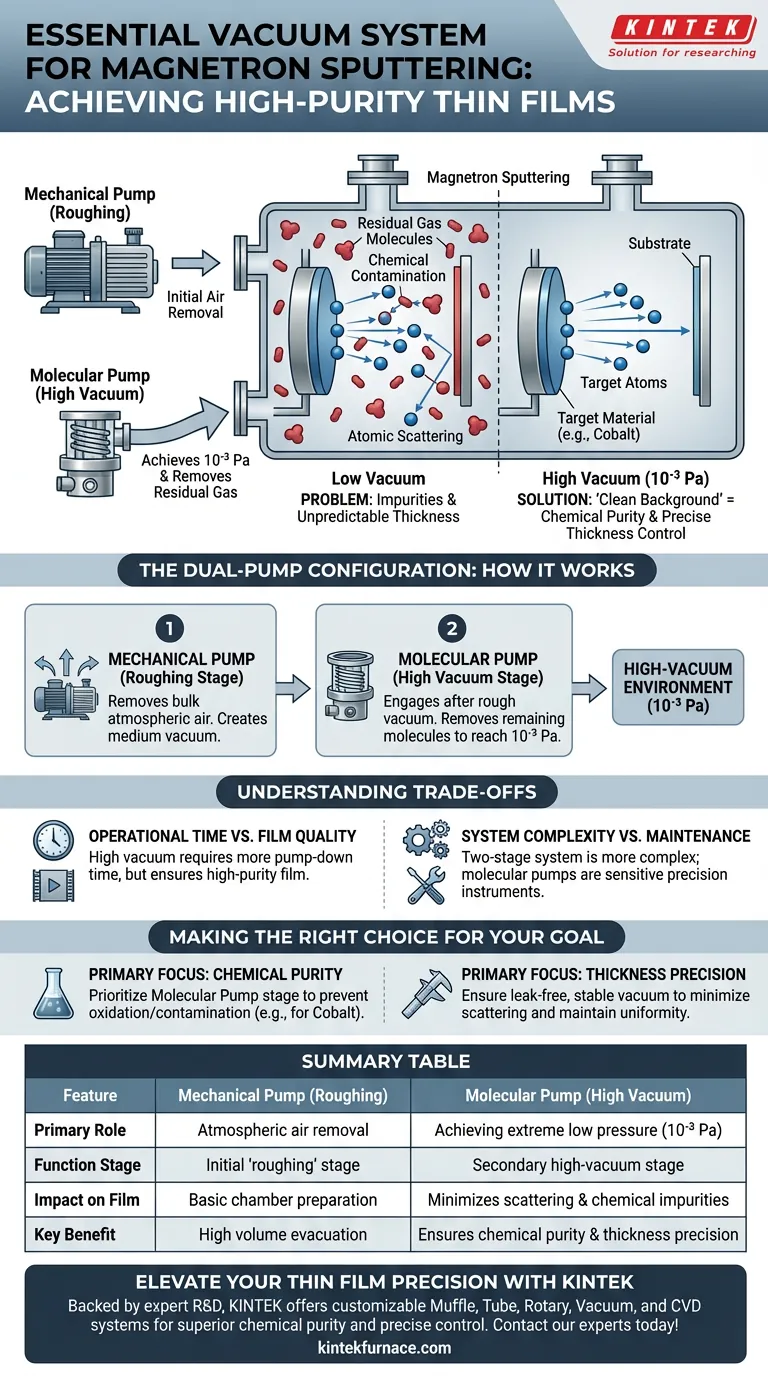

A vacuum system combining mechanical and molecular pumps is critical infrastructure in magnetron sputtering, specifically designed to lower the deposition chamber pressure to extreme levels, such as 10⁻³ Pa. This dual-stage system is required to create a "clean background" environment, which is the defining factor in the quality of the resulting thin film.

Core Takeaway Achieving a high-vacuum environment is essential to minimize the presence of residual gas molecules during deposition. By removing these gases, the system prevents them from chemically reacting with the target material or physically scattering the atom stream, ensuring high chemical purity and precise thickness control.

The Physics of High-Vacuum Deposition

Eliminating Chemical Contamination

The primary threat to thin film quality is the presence of residual gases within the chamber. If the pressure is not sufficiently lowered, these stray molecules remain in the environment.

During the sputtering process, these residual gases can react with the target atoms—such as cobalt—as they travel toward the substrate.

This reaction compromises the chemical purity of the thin film, introducing impurities that can alter its magnetic or electrical properties.

Reducing Atomic Scattering

Beyond chemical reactions, residual gas molecules create physical obstacles for the sputtering atoms.

In a high-pressure environment, target atoms collide with gas molecules, causing them to scatter in unpredictable directions. This is often referred to as a reduction in the "mean free path" of the atoms.

By utilizing a high-vacuum system to reach 10⁻³ Pa, you minimize this scattering. This ensures a direct path for the atoms, allowing for precise control over film thickness and uniformity.

Why the Dual-Pump Configuration is Used

The Role of the Mechanical Pump

A mechanical pump serves as the "roughing" stage of the vacuum system.

It is responsible for removing the bulk of the atmospheric air from the chamber, bringing the pressure down to a medium vacuum level.

The Role of the Molecular Pump

To reach the necessary 10⁻³ Pa level described in the reference, a mechanical pump alone is insufficient.

A molecular pump (such as a turbomolecular pump) is engaged once the rough vacuum is established. This pump is capable of removing the remaining gas molecules to achieve the high-vacuum state required for clean cobalt deposition.

Understanding the Trade-offs

Operational Time vs. Film Quality

Achieving a vacuum of 10⁻³ Pa requires significant pump-down time.

While this ensures a high-purity film, it reduces the overall throughput of the manufacturing process compared to low-vacuum techniques.

System Complexity and Maintenance

Utilizing a two-stage system introduces higher complexity than a single-pump setup.

Molecular pumps are sensitive precision instruments. They require a backing (mechanical) pump to function and are more susceptible to damage from debris or sudden pressure changes.

Making the Right Choice for Your Goal

To determine how strictly you must adhere to high-vacuum protocols, consider your specific application requirements:

- If your primary focus is Chemical Purity: Prioritize the molecular pump stage to ensure pressure hits the 10⁻³ Pa threshold, preventing oxidation or contamination of reactive materials like cobalt.

- If your primary focus is Thickness Precision: Ensure your vacuum system is leak-free and stable, as pressure fluctuations will cause scattering that alters deposition rates and film uniformity.

The integrity of your vacuum system is not just an operational detail; it is the control variable that dictates the purity and geometry of your final product.

Summary Table:

| Feature | Mechanical Pump (Roughing) | Molecular Pump (High Vacuum) |

|---|---|---|

| Primary Role | Atmospheric air removal | Achieving extreme low pressure (10⁻³ Pa) |

| Function Stage | Initial 'roughing' stage | Secondary high-vacuum stage |

| Impact on Film | Basic chamber preparation | Minimizes scattering & chemical impurities |

| Key Benefit | High volume evacuation | Ensures chemical purity & thickness precision |

Elevate Your Thin Film Precision with KINTEK

Don't let residual gas contamination compromise your research or production quality. KINTEK provides industry-leading vacuum solutions tailored for magnetron sputtering and high-temperature lab applications. Backed by expert R&D and manufacturing, we offer a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, all fully customizable to meet your unique thin-film requirements.

Ready to achieve superior chemical purity and precise thickness control? Contact our technical experts today to find the perfect vacuum furnace configuration for your laboratory.

Visual Guide

References

- Nicolas Moreau, J.B. Nagy. Physical Methods for the Preparation of Cobalt Nanoparticles for Use in the Synthesis of Multiwalled Carbon Nanotubes. DOI: 10.3390/inorganics13010007

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Ultra High Vacuum Stainless Steel KF ISO CF Flange Pipe Straight Pipe Tee Cross Fitting

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- 304 316 Stainless Steel High Vacuum Ball Stop Valve for Vacuum Systems

People Also Ask

- How does a high-temperature TOC analyzer assess RCM NSs performance? Verify Mineralization vs Decolorization

- Why is a vacuum drying oven used for BC-FeOOH biochar? Protect Reactivity and Prevent Particle Aggregation

- What is the purpose of the two-step heat treatment process? Optimize Zirconolite-Based Glass-Ceramic Matrices

- What role does quartz sand filler play in a crystal growth furnace? Enhance Thermal Symmetry and Yield

- Why is a homogeneous reactor used for crystallization? Achieve 100% Thermal Uniformity for Pure Crystals

- Why is industrial-grade nitrogen flow introduced during the biochar pyrolysis process? Ensure Safety and Quality

- Why use high-purity Cr, Si, and Y targets for CrSiN-Y coatings? Achieving Superior Thermal Stability & Hardness

- How does a vacuum pressure infiltration system contribute to Diamond/Cu composite green bodies? Achieve 60% Density