Industrial-grade nitrogen functions as a critical isolation barrier throughout the biochar production process. Its primary purpose is to displace normal atmospheric air within the furnace, creating an oxygen-free environment that prevents the raw biomass from igniting into flames and burning down to ash.

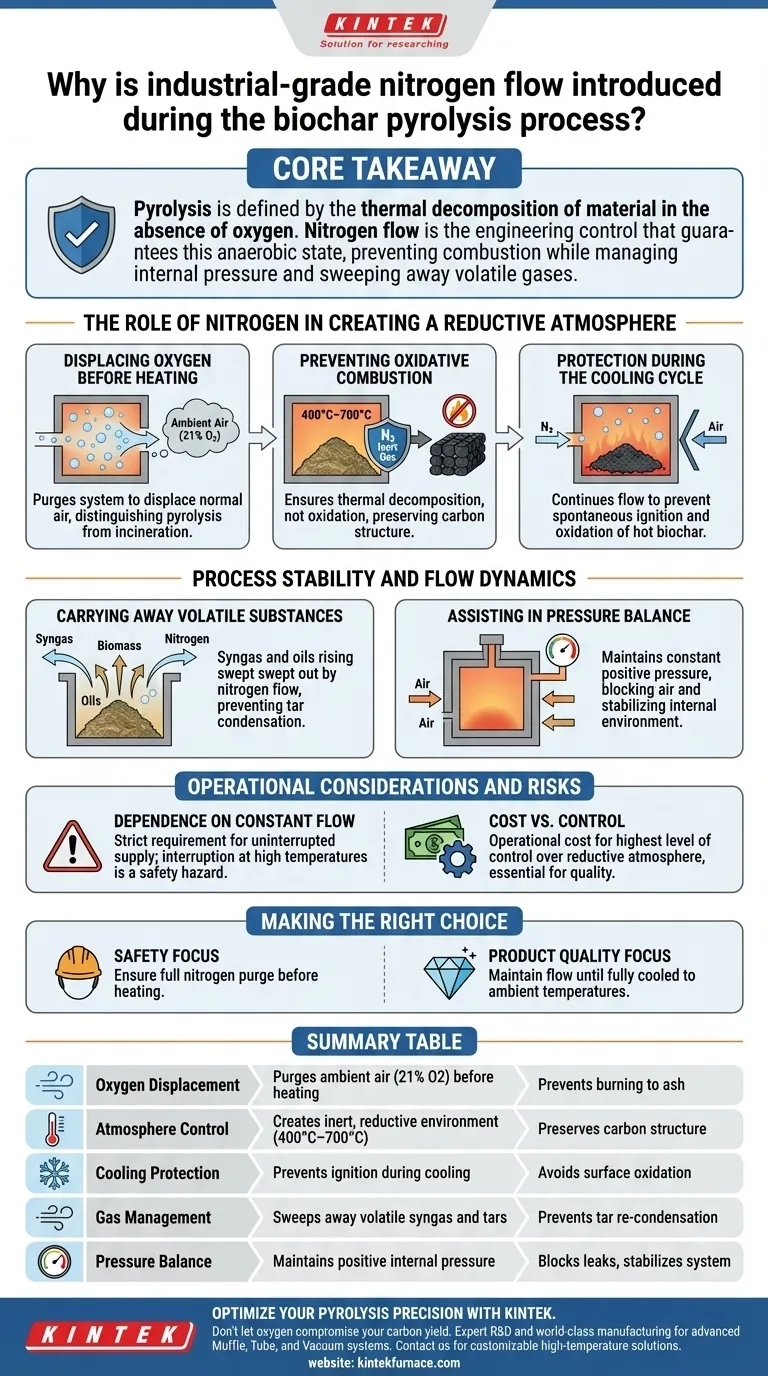

Core Takeaway Pyrolysis is defined by the thermal decomposition of material in the absence of oxygen. Nitrogen flow is the engineering control that guarantees this anaerobic state, preventing combustion while managing internal pressure and sweeping away volatile gases.

The Role of Nitrogen in Creating a Reductive Atmosphere

Displacing Oxygen Before Heating

Before the heating elements are ever engaged, nitrogen is pumped into the furnace to purge the system.

This initial flush pushes out the ambient air, which contains roughly 21% oxygen. Removing this oxygen is the foundational step that distinguishes pyrolysis from simple incineration.

Preventing Oxidative Combustion

If biomass is heated to pyrolysis temperatures (often 400°C–700°C) in the presence of oxygen, it will combust.

Nitrogen serves as an inert protective gas, ensuring the material undergoes thermal decomposition rather than oxidation. This preserves the carbon structure of the biomass, resulting in solid biochar rather than white ash.

Protection During the Cooling Cycle

The need for nitrogen extends beyond the active heating phase.

Nitrogen flow must continue during the cooling cycle to protect the newly formed hot biochar. If air enters the chamber while the biochar is still hot, the material can spontaneously ignite or oxidize, ruining the final product quality.

Process Stability and Flow Dynamics

Carrying Away Volatile Substances

As biomass heats up, it releases a significant volume of volatile gases (syngas) and oils.

The continuous flow of nitrogen helps sweep these released substances out of the reaction zone. This prevents the re-condensation of tars on the biochar and keeps the reaction pathways clear.

Assisting in Pressure Balance

Pyrolysis reactors are closed systems that can experience rapid pressure changes as gases are generated.

The regulated input of nitrogen assists in maintaining a constant, positive pressure balance within the furnace. This prevents external air from leaking in and helps stabilize the internal environment against dangerous pressure spikes.

Operational Considerations and Risks

Dependence on Constant Flow

The primary trade-off of using nitrogen is the strict requirement for uninterrupted supply.

Because nitrogen is the only barrier preventing fire, any interruption in flow during high temperatures can lead to immediate safety hazards. Operators must ensure a consistent source of industrial-grade nitrogen is available for the entire duration of the heating and cooling timeline.

Cost vs. Control

Using industrial-grade nitrogen introduces an operational cost compared to systems that might use self-generated gases.

However, this cost is the price of precision; it offers the highest level of control over the reductive atmosphere, which is essential for producing standardized, high-quality biochar.

Making the Right Choice for Your Goal

To maximize the effectiveness of nitrogen in your pyrolysis system, focus on the timing and consistency of the flow.

- If your primary focus is Safety: Ensure the furnace is fully purged with nitrogen to displace all air before the temperature begins to rise.

- If your primary focus is Product Quality: Maintain nitrogen flow until the biochar has fully cooled to ambient temperatures to prevent surface oxidation.

Nitrogen is not just a utility; it is the defining variable that allows pyrolysis to occur safely and effectively.

Summary Table:

| Function of Nitrogen | Purpose in Pyrolysis Process | Impact on Biochar Quality |

|---|---|---|

| Oxygen Displacement | Purges ambient air (21% O2) before heating starts | Prevents biomass from burning to ash |

| Atmosphere Control | Creates an inert, reductive environment (400°C–700°C) | Preserves carbon structure and integrity |

| Cooling Protection | Prevents spontaneous ignition during the cooling cycle | Avoids surface oxidation of hot biochar |

| Gas Management | Sweeps away volatile syngas and condensable tars | Prevents tar re-condensation on products |

| Pressure Balance | Maintains positive internal furnace pressure | Blocks external air leaks and stabilizes system |

Optimize Your Pyrolysis Precision with KINTEK

Don't let oxygen compromise your carbon yield. At KINTEK, we understand that the difference between high-quality biochar and waste ash lies in precise atmospheric control. Backed by expert R&D and world-class manufacturing, we provide advanced Muffle, Tube, and Vacuum systems specifically designed to handle rigorous nitrogen flow requirements. Whether you need a standard laboratory furnace or a customizable high-temperature solution, our equipment ensures the anaerobic stability your research and production demand.

Ready to elevate your material processing? Contact KINTEK today to consult with our experts on the perfect furnace for your unique pyrolysis needs.

Visual Guide

References

- João Arthur Antonângelo, Hailin Zhang. Fertilizer potential of biochar and ryegrass productivity in metal-contaminated soil. DOI: 10.3389/fpls.2024.1475939

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

People Also Ask

- How is a mass spectrometer utilized in TPO tests for catalysts? Enhance Your Material Characterization

- What are the main types of heat treatment furnaces? Choose the Right Furnace for Your Lab or Industry

- What is quenching, and why is it important? Achieve Superior Material Hardness and Strength

- How does a sealed ceramic boat impact SPAN sulfur content? Unlock 53.62% Retention for High-Energy Cathodes

- Why is High-Temperature Annealing Required for WS2 Gas Sensors? Stabilize Performance & Eliminate Drift

- How does the orientation of glass within a tempering furnace affect quality? Optimize Optical and Physical Properties

- What is the main purpose of annealing? A Guide to Controlling Material Properties

- What are the advantages of Spark Plasma Sintering (SPS) for TiC alloys? Preserve Precision and Microstructure