A laboratory circulating air drying oven acts as a precision instrument for structural stabilization, not just moisture removal. Its primary role in the post-treatment of composite membranes is to generate a uniform thermal field—typically around 80°C—which drives the critical process of thermal annealing. This controlled heating phase is essential for transforming the membrane from a raw state into a durable, high-performance component.

Core Takeaway: The circulating air oven is essential for enhancing mechanical and chemical integrity. By promoting polymer chain rearrangement and eliminating internal stresses, it compacts the membrane structure, ensuring the final product is stable enough for long-term deployment.

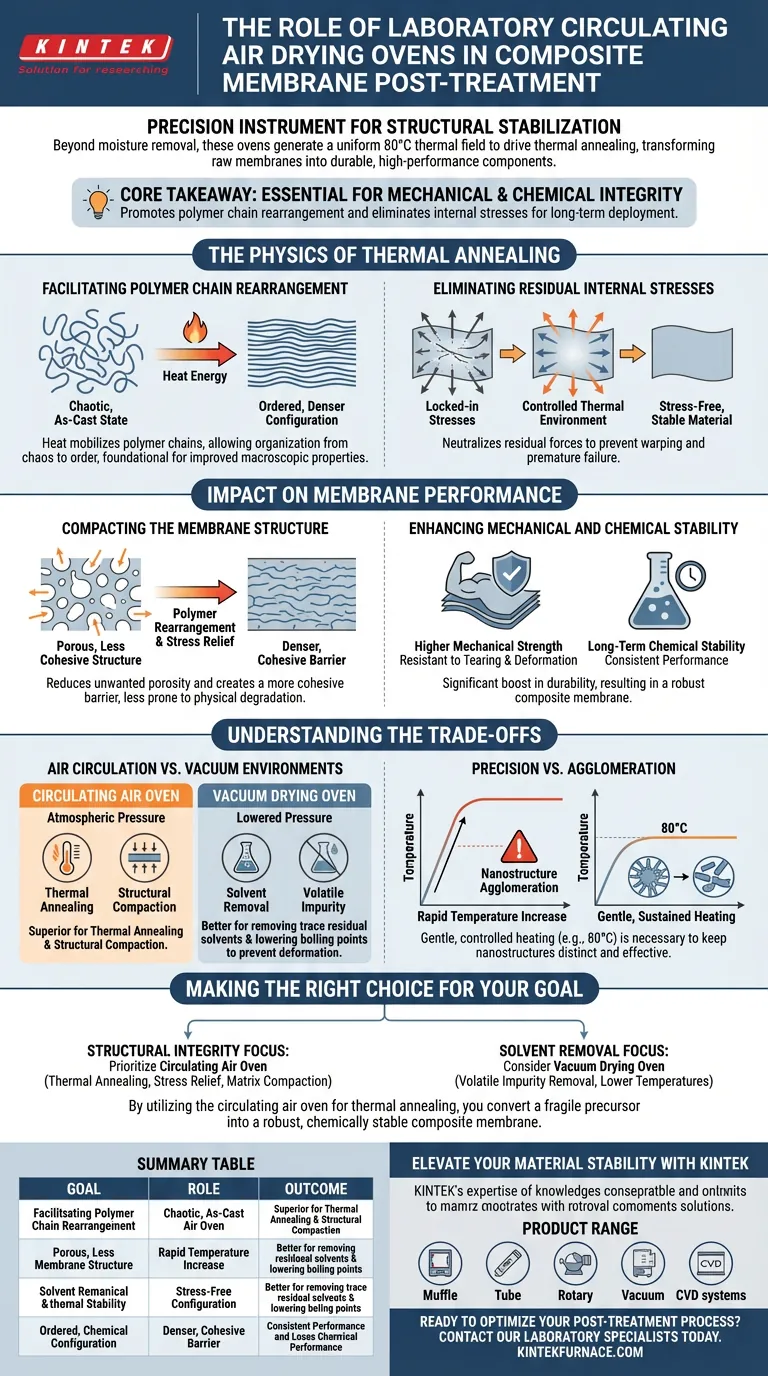

The Physics of Thermal Annealing

Facilitating Polymer Chain Rearrangement

The heat provided by the circulating air creates the necessary energy for polymer chains within the membrane to mobilize.

This allows the chains to reorganize themselves from a chaotic, as-cast state into a more ordered configuration. This rearrangement is the foundational step for improving the material's macroscopic properties.

Eliminating Residual Internal Stresses

During the initial membrane-forming process, significant internal stresses are often locked into the material.

If left untreated, these stresses can lead to warping or premature failure. The oven’s controlled thermal environment effectively relaxes the material, neutralizing these residual forces.

Impact on Membrane Performance

Compacting the Membrane Structure

As polymer chains rearrange and stresses dissipate, the overall physical structure of the membrane becomes denser.

This "compaction" reduces porosity where it is unwanted and creates a more cohesive barrier. A compacted structure is less prone to physical degradation under operational pressure.

Enhancing Mechanical and Chemical Stability

The ultimate result of annealing in a circulating air oven is a significant boost in durability.

The membrane gains higher mechanical strength, making it more resistant to tearing or physical deformation. Simultaneously, the refined structure improves long-term chemical stability, ensuring consistent performance over time.

Understanding the Trade-offs

Air Circulation vs. Vacuum Environments

While the circulating air oven is superior for thermal annealing and structural compaction, it operates at atmospheric pressure.

If your primary goal is the removal of trace residual solvents (like acetonitrile or acetic acid) to prevent plasticization, a vacuum drying oven may be more appropriate. Supplementary data indicates that vacuum environments are better suited for lowering the boiling point of solvents to prevent fiber deformation or oxidation during drying.

Precision vs. Agglomeration

Circulating air provides a constant thermal environment, but care must be taken with the heating rate.

Rapid temperature increases in standard ovens can sometimes cause nanostructures to agglomerate. Gentle, sustained heating (e.g., maintaining 80°C for strictly controlled durations) is necessary to keep structures distinct and effective.

Making the Right Choice for Your Goal

To maximize the effectiveness of your post-treatment strategy, match the equipment to your specific objective.

- If your primary focus is Structural Integrity: Prioritize the circulating air drying oven to perform thermal annealing, relieve stress, and compact the polymer matrix.

- If your primary focus is Solvent Removal: Consider a vacuum drying oven to remove volatile impurities at lower temperatures without risking oxidation or plasticization.

By utilizing the circulating air oven for thermal annealing, you convert a fragile precursor into a robust, chemically stable composite membrane.

Summary Table:

| Post-Treatment Goal | Role of Circulating Air Oven | Primary Outcome |

|---|---|---|

| Polymer Alignment | Facilitates chain rearrangement | Ordered, denser membrane structure |

| Stress Relief | Neutralizes internal forces | Prevents warping and material failure |

| Durability | Drives thermal annealing | Enhanced mechanical and chemical stability |

| Structural Density | Compacts the polymer matrix | Reduced unwanted porosity and high cohesion |

Elevate Your Material Stability with KINTEK

Precision is non-negotiable when transitioning fragile precursors into high-performance composite membranes. At KINTEK, we understand the critical role of uniform thermal fields in polymer annealing. Backed by expert R&D and manufacturing, we offer a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, along with specialized laboratory high-temp furnaces tailored to your unique research needs.

Whether you require atmospheric precision for structural compaction or vacuum environments for solvent removal, our customizable solutions ensure your membranes achieve maximum mechanical and chemical integrity.

Ready to optimize your post-treatment process? Contact our laboratory specialists today to find the perfect drying solution for your composite membrane development.

Visual Guide

References

- Omneya A. Koriem, Marwa Elkady. Synthesis of high-performance biocompatible polymeric membranes incorporated with zirconium-based MOF for an enhanced brackish water RO desalination. DOI: 10.1007/s10570-023-05723-6

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Small Rotary Kiln Calciner

- 1200℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Kiln for Pyrolysis Plant Heating

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

People Also Ask

- How does industrial-scale forging equipment influence the morphology of primary carbonitrides in H13 tool steel?

- What is the importance of the feeding system and ore distributing device? Unlock Peak Oil Shale Retorting Efficiency

- What is the function of an industrial drying oven in PET waste pretreatment? Optimize Your Activated Carbon Production

- What is the significance of using different sizes of steel working ampoules? Precision vs. Efficiency in Lab Research

- What are the primary advantages of industrial microwave heating equipment? Enhanced Uranium Recovery Through Innovation

- Why are advanced materials and composites important? Unlock Next-Gen Performance in Aerospace, Auto, and More

- What is the function of magnetron sputtering equipment in Diamond/Cu composites? Enhance Bonding with Precision Coating

- What is the role of sintering in CsPbBr3-SiO2 preparation? Unlock Ultra-Stability with Precise Thermal Sealing