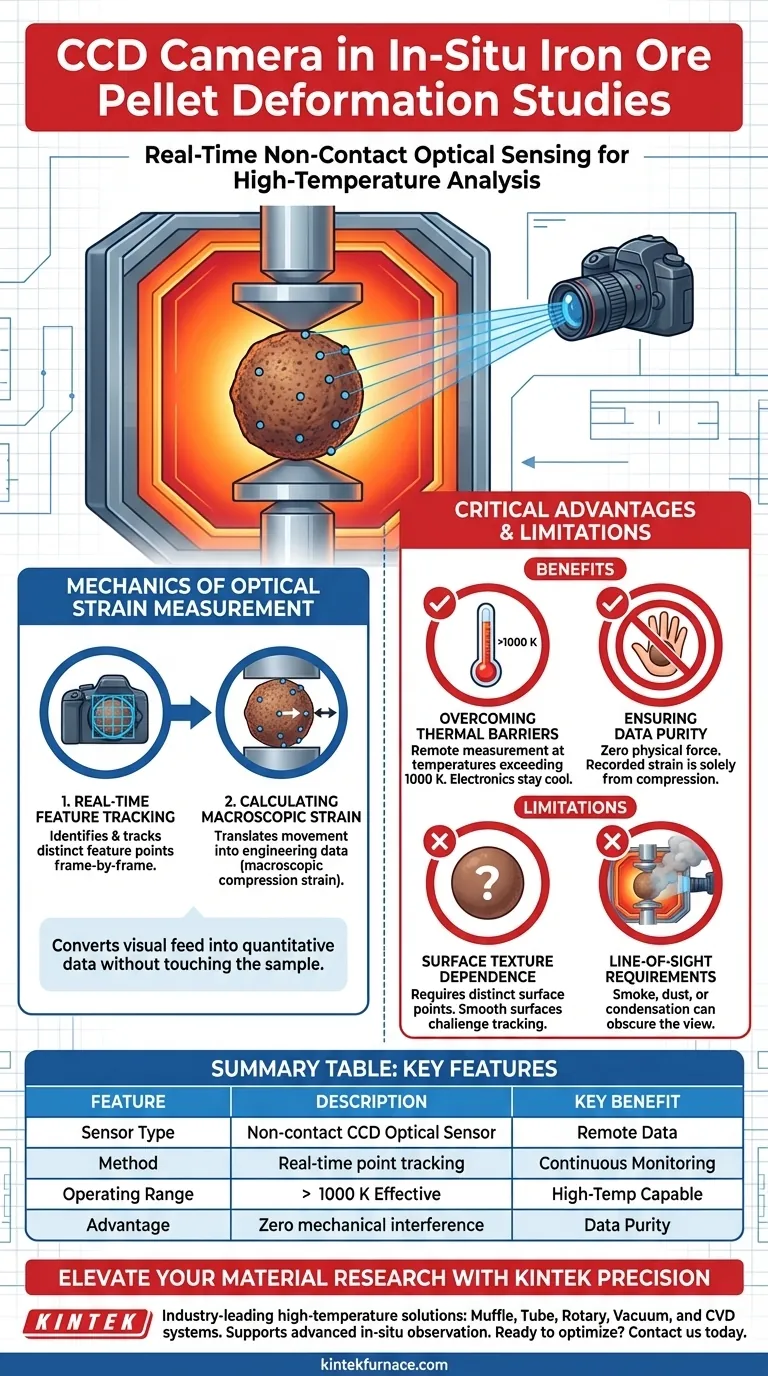

In the context of studying iron ore pellet deformation, a CCD camera serves as a non-contact optical sensor integrated into an in-situ observation system. Its primary function is to monitor the compression process in real-time by tracking specific feature points on the specimen's surface to calculate macroscopic compression strain.

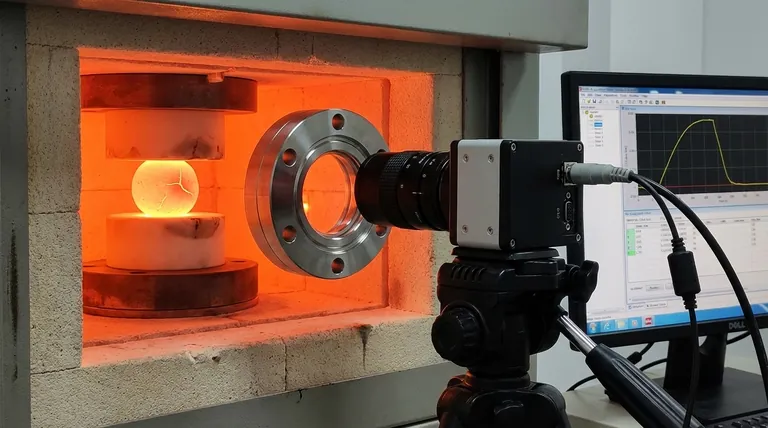

Physical contact with specimens is often impossible or detrimental in extreme testing conditions. The core value of the CCD camera is its ability to extract high-precision deformation data remotely, enabling accurate measurement at temperatures exceeding 1000 K.

The Mechanics of Optical Strain Measurement

Real-Time Feature Tracking

The CCD camera does not simply record video; it acts as a data acquisition device. The system identifies specific, distinct feature points on the surface of the iron ore pellet.

As the pellet undergoes compression, the camera tracks the displacement of these points frame by frame.

Calculating Macroscopic Strain

The system translates the movement of these visual feature points into engineering data. By measuring how the distance between points changes, the system calculates macroscopic compression strain.

This effectively converts a visual image feed into a quantitative dataset without touching the sample.

Why Non-Contact Observation is Critical

Overcoming Thermal Barriers

Standard physical strain gauges often fail or lose accuracy in extreme heat. The primary reference highlights that this optical method is specifically designed for environments exceeding 1000 K.

The CCD camera allows the sensor electronics to remain outside the heat zone while still monitoring the reaction at the core.

Ensuring Data Purity

Physical sensors can introduce mechanical interference, potentially altering how a fragile pellet deforms. By using a camera, the measurement process exerts zero physical force on the specimen.

This ensures that the recorded strain is solely a result of the experimental compression, not an artifact of the measurement tool.

Understanding the Limitations

Dependence on Surface Texture

The system relies entirely on tracking "feature points." If the specimen surface is perfectly smooth or lacks contrast, the software may struggle to lock onto points to track.

Line-of-Sight Requirements

Because this is an optical method, it requires a clear, unobstructed view of the specimen. Smoke, dust, or condensation generated during the high-temperature process can obscure the lens and compromise data integrity.

Optimizing Your Observation Setup

To get the most out of an in-situ CCD observation system, align your approach with your specific testing parameters:

- If your primary focus is high-temperature testing: Ensure your optical path allows the camera to remain at a safe distance while maintaining a clear view of the sample at >1000 K.

- If your primary focus is strain accuracy: Verify that your specimen has distinct surface features that the camera can easily track to prevent data drift.

By shifting from contact-based to optical measurement, you secure data integrity in environments where physical sensors simply cannot survive.

Summary Table:

| Feature | Description |

|---|---|

| Sensor Type | Non-contact CCD Optical Sensor |

| Measurement Method | Real-time feature point tracking and displacement mapping |

| Key Metric | Macroscopic compression strain |

| Operating Range | Effective at temperatures > 1000 K |

| Core Advantage | Zero mechanical interference; data purity in extreme heat |

| Critical Requirement | Clear line-of-sight and distinct specimen surface texture |

Elevate Your Material Research with KINTEK Precision

Precise data collection in high-temperature environments requires more than just a camera—it demands a robust, integrated thermal system. KINTEK provides industry-leading high-temperature solutions, including Muffle, Tube, Rotary, Vacuum, and CVD systems, all engineered to support advanced in-situ observation.

Backed by expert R&D and specialized manufacturing, our equipment is fully customizable to meet your unique laboratory needs. Ensure your data integrity and overcome thermal barriers with our expert-grade furnace technology.

Ready to optimize your high-temperature testing? Contact our technical experts today to discuss your specific requirements.

Visual Guide

Related Products

- Ultra High Vacuum CF Observation Window Flange with High Borosilicate Glass Sight Glass

- Ultra High Vacuum Observation Window Stainless Steel Flange Sapphire Glass Sight Glass for KF

- Ultra High Vacuum CF Flange Stainless Steel Sapphire Glass Observation Sight Window

- Ultra High Vacuum Observation Window KF Flange 304 Stainless Steel High Borosilicate Glass Sight Glass

People Also Ask

- How does temperature control in carbonization furnaces affect structural battery anodes? Optimize Fiber Performance

- What are the functions of a rotary evaporator and a vacuum drying oven in LTO sol-gel? Optimize Your Synthesis Process

- Why introduce high-purity N2 during cooling after roasting? Preserve Sample Integrity and Prevent Oxidation

- What role does a high-temperature furnace play in the sealing process? Precision Thermal Control for Fiber Sealing

- How is a mass spectrometer utilized in TPO tests for catalysts? Enhance Your Material Characterization

- What role does a precision mass loss measurement system play? Identifying Vapor Pressure in High-Temp Furnaces

- How does a dual-stage salt bath design address steel wire sorbitization? Master Precision Gradient Cooling

- What is the primary function of a vacuum oven for Mo-based catalyst precursors? Ensure Purity & Pore Integrity