In essence, an electric muffle furnace is a specialized oven that provides high-temperature heating within a completely isolated and controlled environment. Its primary function is to heat a material without exposing it to the contaminants of combustion or the direct radiation of the heating elements themselves, ensuring process purity and thermal uniformity.

The core value of a muffle furnace lies in its name: the muffle. This insulated inner chamber separates the sample from the heating source, preventing contamination and delivering pure, uniform heat for sensitive laboratory and industrial processes.

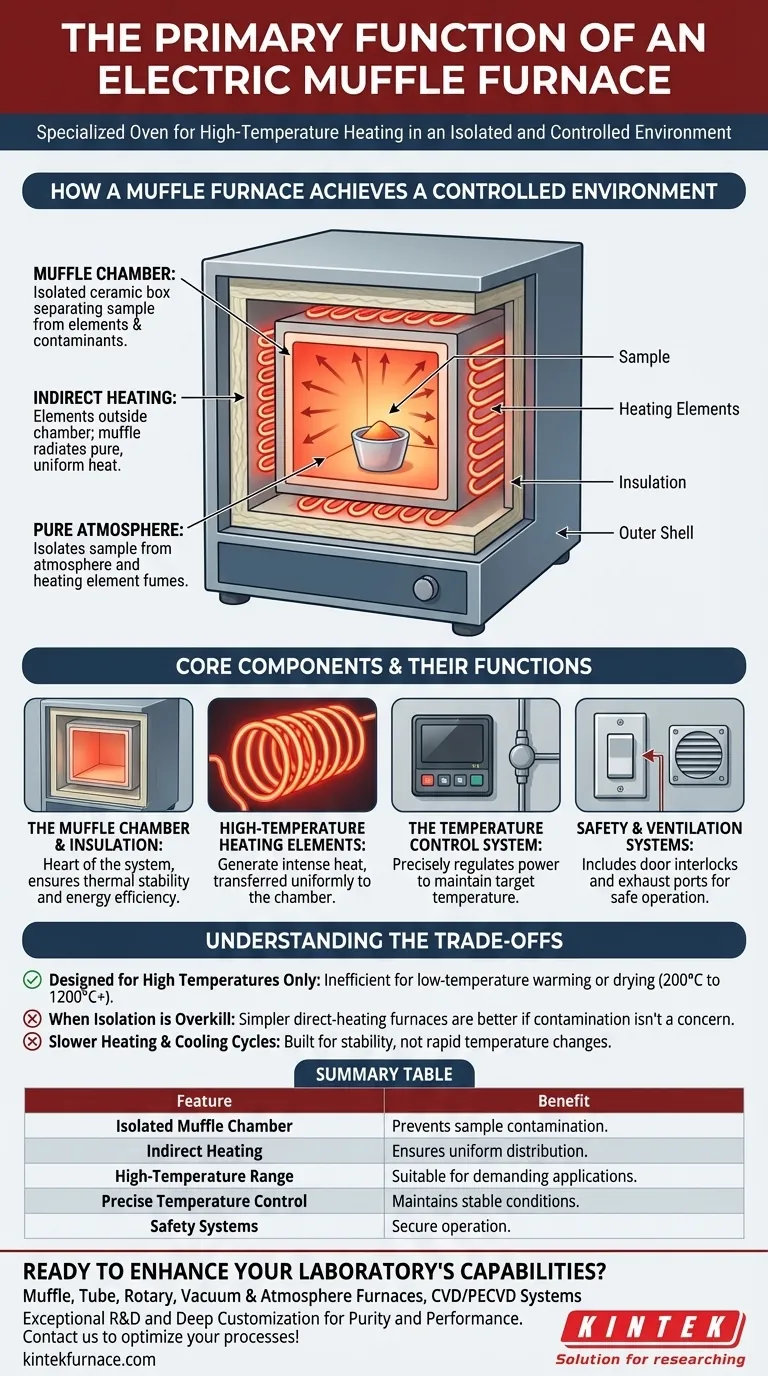

How a Muffle Furnace Achieves a Controlled Environment

The design of a muffle furnace is purpose-built to solve the problem of contamination and uneven heating common in simpler high-temperature ovens.

The Central Role of the Muffle Chamber

The "muffle" is the defining component. It is an insulated box, typically made of a ceramic material, that sits inside the main furnace structure.

Your sample or material is placed inside this muffle chamber, not in the general furnace cavity.

The Principle of Indirect Heating

The furnace's heating elements, such as Kanthal or Nichrome coils, are located outside the muffle chamber.

These elements heat the muffle chamber itself, which then radiates heat uniformly to the material inside. This indirect heating is critical, as it ensures the sample never comes into contact with the heating elements or any potential fumes.

Creating a Pure Atmosphere

Historically, the muffle isolated materials from the soot and gases of fuel combustion. In modern electric furnaces, it isolates the sample from the atmosphere and the heating elements.

This separation is crucial for processes like ashing, where a clean, oxygen-rich environment is needed, or sintering, which may require an inert atmosphere.

Core Components and Their Functions

Understanding the key parts of a muffle furnace reveals why it is so effective for its intended tasks.

The Muffle Chamber and Insulation

This is the heart of the system. The chamber's material and the surrounding insulation layers are designed to withstand extreme temperatures while preventing heat loss, ensuring energy efficiency and stability.

High-Temperature Heating Elements

These coils surround the muffle chamber and are responsible for generating the intense heat required. Their placement ensures that heat is transferred evenly to the chamber walls.

The Temperature Control System

A sophisticated controller, connected to temperature sensors (like thermocouples), acts as the brain of the furnace. It precisely regulates the power sent to the heating elements to achieve and maintain the target temperature.

Safety and Ventilation Systems

A safety switch that cuts power when the door is opened is a standard feature. Many furnaces also include an exhaust port or ventilation system to safely expel any fumes or gases released from the sample during heating.

Understanding the Trade-offs

While powerful, a muffle furnace is a specialized tool, not a one-size-fits-all solution.

Designed for High Temperatures Only

Muffle furnaces are engineered for high-temperature applications, often ranging from 200°C to over 1200°C. They are inefficient and ill-suited for low-temperature warming or drying.

When Isolation is Overkill

The primary benefit is preventing contamination. If your process is robust and not sensitive to direct heating or atmospheric impurities, a simpler and potentially more cost-effective direct-heating furnace may be sufficient.

Slower Heating and Cooling Cycles

The significant thermal mass from the heavy insulation means muffle furnaces typically heat up and cool down more slowly than less-insulated ovens. They are built for stability, not rapid temperature changes.

Making the Right Choice for Your Goal

Select your heating equipment based on the specific requirements of your process.

- If your primary focus is material purity and analysis (ashing, elemental analysis): A muffle furnace is essential, as its isolated chamber prevents sample contamination.

- If your primary focus is high-temperature heat treatment (sintering, annealing, hardening): A muffle furnace is ideal for providing the stable, uniform, and controllable thermal environment required for predictable results.

- If your primary focus is simply heating a material without contamination concerns: A less specialized high-temperature oven may be a more efficient and economical choice.

Ultimately, choosing a muffle furnace is a decision to prioritize process purity and thermal uniformity above all else.

Summary Table:

| Feature | Benefit |

|---|---|

| Isolated Muffle Chamber | Prevents sample contamination from heating elements and atmosphere |

| Indirect Heating | Ensures uniform temperature distribution for consistent results |

| High-Temperature Range (200°C to 1200°C+) | Suitable for demanding applications like ashing and sintering |

| Precise Temperature Control | Maintains stable thermal conditions for reliable processes |

| Safety Systems | Includes door interlocks and ventilation for secure operation |

Ready to enhance your laboratory's capabilities with a tailored high-temperature furnace? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced solutions like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we can precisely meet your unique experimental requirements for purity and performance. Contact us today to discuss how our furnaces can optimize your processes and deliver superior results!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the key role of a muffle furnace in the pretreatment of boron sludge and szaibelyite? Unlock Higher Process Efficiency

- What is the role of a muffle furnace in the study of biochar regeneration and reuse? Unlock Sustainable Water Treatment

- What substances are prohibited from being introduced into the furnace chamber? Prevent Catastrophic Failure

- What metals cannot be heated by induction? Understanding Material Suitability for Efficient Heating

- What is the role of a muffle furnace in the synthesis of water-soluble Sr3Al2O6? Precision in SAO Production