In metallurgy, box type electric furnaces are primarily used for three core functions: the precise heat treatment of solid metals to alter their properties, the synthesis of materials from powders through sintering, and the preparation of samples for chemical analysis. These furnaces provide the controlled, high-temperature environment essential for manipulating a metal's internal microstructure.

The true value of a box furnace in metallurgy is not simply its ability to get hot, but its capacity for precise thermal control. This control allows metallurgists to dictate a metal's final characteristics—from hardness and toughness to ductility—by carefully managing its heating and cooling cycles.

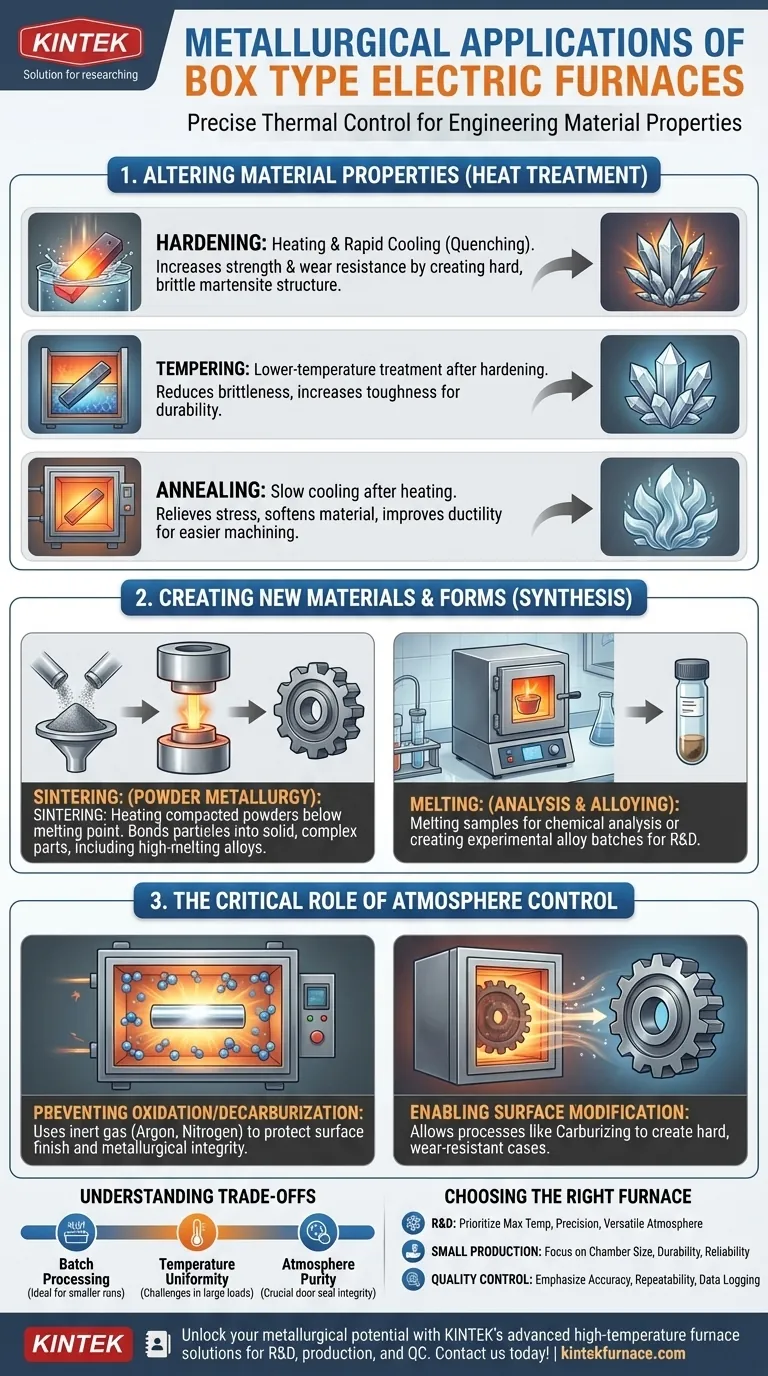

Altering Material Properties Through Heat Treatment

The most common application of box furnaces is heat treatment, a group of processes used to intentionally modify a metal's mechanical properties without changing its shape. Each process uses a specific thermal profile to achieve a different outcome.

Hardening

Hardening involves heating steel to a critical temperature and then rapidly cooling it (quenching). This process transforms the steel's internal crystal structure into a very hard but brittle state known as martensite, dramatically increasing its strength and wear resistance.

Tempering

Parts that have been hardened are often too brittle for practical use. Tempering is a subsequent, lower-temperature heat treatment that reduces this brittleness and increases toughness, creating a more durable and reliable final component.

Annealing

Annealing is essentially the opposite of hardening. The metal is heated and then very slowly cooled, which relieves internal stresses, softens the material, and improves its ductility. This makes the metal easier to machine, form, or stamp in subsequent manufacturing steps.

Creating New Materials and Forms

Box furnaces are also used in processes that create solid components from non-solid starting materials, particularly in laboratory and specialized production settings.

Sintering for Powder Metallurgy

Sintering is a process where fine metal powders are compacted and then heated in a box furnace to a temperature below their melting point. The heat and pressure cause the powder particles to bond together, forming a solid, often complex, part. This is critical for materials with extremely high melting points or for creating unique alloys.

Melting for Analysis and Alloying

In a laboratory environment, small box furnaces (often called muffle furnaces) are used to melt down metal samples. This is done to prepare the material for chemical analysis, such as by spark spectrometry, or to create small, experimental batches of new alloys for research and development.

The Critical Role of Atmosphere Control

Many metallurgical processes are compromised by the presence of oxygen at high temperatures. Specialized box furnaces, known as atmosphere furnaces, allow for precise control over the gaseous environment inside the chamber.

Preventing Oxidation and Decarburization

By filling the furnace chamber with an inert gas like argon or nitrogen, oxidation (rusting) and decarburization (loss of carbon from the surface of steel) are prevented. This ensures the material's surface finish and metallurgical properties are preserved.

Enabling Surface Modification

Atmosphere control also allows for processes that add elements to the metal's surface. In carburizing, a carbon-rich atmosphere is used to diffuse carbon into the surface of a steel part, creating a hard, wear-resistant "case" over a tougher core.

Understanding the Trade-offs

While versatile, box furnaces are not the solution for every application. Understanding their limitations is key to using them effectively.

Batch Processing vs. Continuous Flow

Box furnaces are batch processors by nature. An operator must load the parts, run the thermal cycle, and then unload them. This is ideal for labs, custom jobs, or small production runs but is inefficient for high-volume manufacturing, where continuous tunnel furnaces are preferred.

Temperature Uniformity

Achieving perfect temperature uniformity throughout the entire chamber can be a challenge, especially in larger furnaces or with densely packed loads. This can lead to slight variations in the properties of parts placed in different locations within the furnace.

Atmosphere Purity

For processes requiring high-purity inert atmospheres, maintaining that environment can be difficult. The integrity of door seals is critical, as even small leaks can introduce oxygen and compromise the process.

Making the Right Choice for Your Goal

Selecting and using a box furnace depends entirely on your objective.

- If your primary focus is research and development: Prioritize a furnace with maximum temperature range, precise PID controls, and versatile atmosphere options (including vacuum or inert gas) to accommodate a wide variety of experiments.

- If your primary focus is small-scale production or tool-room heat treating: Focus on chamber size, durability, and reliability. Atmosphere control may be essential depending on whether you are working with high-carbon steels.

- If your primary focus is quality control and analysis: Emphasize temperature accuracy, repeatability, and data-logging capabilities to ensure your test results are consistent and traceable.

Ultimately, the box furnace is a fundamental tool that gives metallurgists the power to purposefully engineer the performance of metallic materials.

Summary Table:

| Application | Key Process | Purpose |

|---|---|---|

| Heat Treatment | Hardening, Tempering, Annealing | Alter mechanical properties like hardness and ductility |

| Material Synthesis | Sintering, Melting | Create solid parts from powders or prepare samples for analysis |

| Atmosphere Control | Inert gas or vacuum environments | Prevent oxidation, enable surface modification |

Unlock the full potential of your metallurgical processes with KINTEK's advanced high-temperature furnace solutions. Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with tailored options like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your unique experimental needs, whether for research, production, or quality control. Contact us today to discuss how our furnaces can enhance your material properties and efficiency!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- How do you clean a muffle furnace? Ensure Peak Performance and Longevity

- What is the role of a muffle furnace in the synthesis of water-soluble Sr3Al2O6? Precision in SAO Production

- Why is a high-performance muffle furnace required for the calcination of nanopowders? Achieve Pure Nanocrystals

- What role does a muffle furnace play in the preparation of MgO support materials? Master Catalyst Activation

- Can a muffle furnace be used for pyrolysis? Unlock Precise Thermal Decomposition