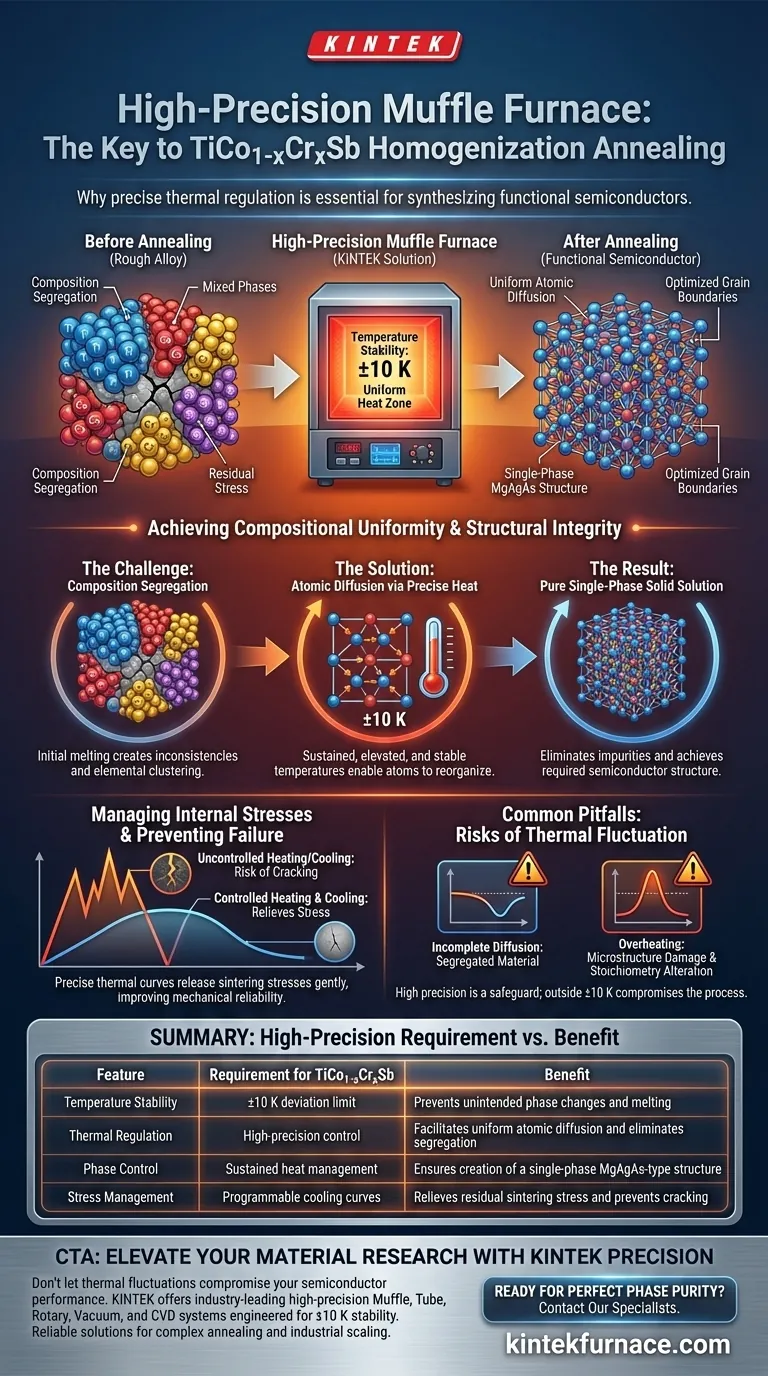

The necessity of a high-precision muffle furnace stems directly from the strict thermal requirements required to synthesize high-quality TiCo1-xCrxSb. This equipment provides the critical temperature stability—typically within $\pm 10$ K—needed to facilitate uniform atomic diffusion over long durations. Without this specific control, it is impossible to eliminate compositional segregation or achieve the homogeneous, single-phase structure required for the material's semiconductor performance.

Precise thermal regulation is the mechanism that transforms a rough alloy into a functional semiconductor. A high-precision muffle furnace ensures the creation of a pure, single-phase MgAgAs-type structure by maintaining temperatures within a tight $\pm 10$ K window.

Achieving Compositional Uniformity

The Challenge of Composition Segregation

During the initial melting process of TiCo1-xCrxSb, the material naturally develops inconsistencies. This results in composition segregation, where the elements are not distributed continuously throughout the alloy.

The Role of Atomic Diffusion

To correct this segregation, atoms must move and reorganize themselves within the solid material. This process, known as atomic diffusion, requires sustained, elevated temperatures to occur effectively.

Precision is Paramount

The muffle furnace provides the exact environment needed for this diffusion. By holding the temperature stable within $\pm 10$ K, the furnace ensures that diffusion happens uniformly without causing unintended phase changes or melting.

Structural Integrity and Phase Formation

Forming the MgAgAs Structure

The ultimate goal of this annealing process is to create a single-phase semiconductor solid solution. Specifically, the material must adopt an MgAgAs-type structure to function correctly.

Eliminating Impurities

Consistent heat allows the material to settle into this specific crystalline arrangement. If the temperature fluctuates significantly, the material may retain mixed phases, degrading its semiconductor properties.

Optimizing Grain Boundaries

Beyond phase formation, precise annealing helps optimize the internal grain boundary structures. This optimization is crucial for defining the material's electronic and thermal characteristics.

Managing Internal Stresses

Relieving Sintering Stress

Processes prior to annealing, such as sintering, often leave the material with residual internal stresses. These stresses can lead to mechanical failure or cracking if not addressed.

Controlled Heating and Cooling

A high-quality muffle furnace allows for precisely controllable heating and cooling curves. By managing the rate of temperature change, the furnace releases these internal stresses gently, improving the mechanical reliability of the final material.

Common Pitfalls to Avoid

The Risk of Thermal Fluctuation

If the temperature deviates outside the $\pm 10$ K range, the homogenization process is compromised. Lower temperatures may result in incomplete diffusion, leaving the material segregated and ineffective.

Overheating Dangers

Conversely, temperature spikes can damage the microstructure or alter the stoichiometry. High precision acts as a safeguard against these excursions, ensuring the synthesis yields a usable semiconductor.

Ensuring Material Quality

To maximize the quality of your TiCo1-xCrxSb production, match your furnace capabilities to your specific material goals.

- If your primary focus is phase purity: Ensure your furnace is calibrated to maintain stability strictly within $\pm 10$ K to guarantee the formation of the MgAgAs structure.

- If your primary focus is mechanical reliability: Utilize the furnace's programmable heating and cooling curves to eliminate residual stresses and prevent cracking.

Ultimately, the muffle furnace is not just a heating element; it is the precision tool that dictates the structural and functional success of the final semiconductor.

Summary Table:

| Feature | Requirement for TiCo1-xCrxSb | Benefit |

|---|---|---|

| Temperature Stability | $\pm 10$ K deviation limit | Prevents unintended phase changes and melting |

| Thermal Regulation | High-precision control | Facilitates uniform atomic diffusion and eliminates segregation |

| Phase Control | Sustained heat management | Ensures creation of a single-phase MgAgAs-type structure |

| Stress Management | Programmable cooling curves | Relieves residual sintering stress and prevents cracking |

Elevate Your Material Research with KINTEK Precision

Don't let thermal fluctuations compromise your semiconductor performance. KINTEK provides industry-leading thermal solutions backed by expert R&D and manufacturing. Our high-precision Muffle, Tube, Rotary, Vacuum, and CVD systems are engineered to provide the exact $\pm 10$ K stability required for advanced material synthesis like TiCo1-xCrxSb.

Whether you need customizable lab furnaces for complex annealing or high-temp systems for industrial scaling, KINTEK offers the reliability your research demands.

Ready to achieve perfect phase purity? Contact us today to discuss your unique needs with our specialists.

Visual Guide

References

- Volodymyr Krayovskyy, А. Horyn. SIMULATION OF CHARACTERISTICS OF SENSITIVE ELEMENTS OF TEMPERATURE CONVERTERS BASED ON TiCo1-xCrxSb. DOI: 10.23939/istcmtm2024.04.030

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What is the purpose of using a high-temperature oven for the pretreatment of anhydrous calcium chloride?

- What is the primary advantage of a muffle furnace compared to other types of furnaces? Superior Purity and Element Protection

- What is the primary purpose of using a high-temperature box resistance furnace during the pretreatment of kaolin catalysts? Optimize Performance & Structure

- What are some typical heat processing applications for Box Furnaces? Discover Versatile Solutions for Metals and Materials

- What maintenance is required for a muffle furnace? Ensure Long-Term Reliability and Safety

- Why is precise temperature control in a muffle furnace critical for 1250°C homogenization of AlCoCrFeNi alloys?

- What is a muffle furnace and its primary use? Discover High-Temp, Contamination-Free Heating Solutions

- What temperature range can muffle furnaces typically operate within? Find the Perfect Fit for Your Lab