The primary advantage of a muffle furnace is its design, which physically isolates the material being heated from the heating elements. This separation, achieved by a chamber or "muffle," prevents direct contact with combustion byproducts or element degradation, ensuring a contamination-free environment and significantly extending the life of the heating elements.

The core value of a muffle furnace is not just its ability to reach high temperatures, but its capacity to create an exceptionally pure and controlled heating environment. This makes it an indispensable tool for processes where sample integrity is paramount.

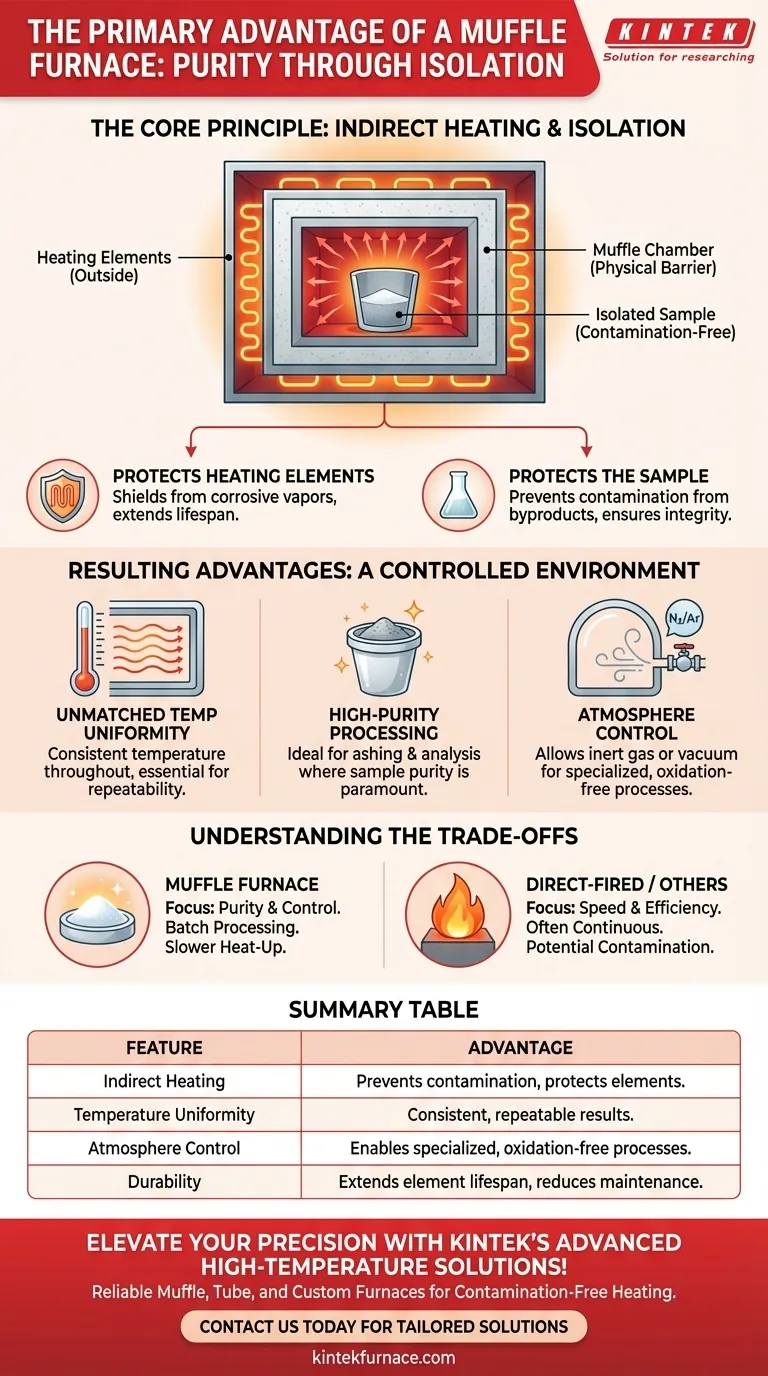

The Core Principle: Indirect Heating and Isolation

The defining feature of a muffle furnace is not its heat source, but how that heat is delivered. The design is centered on separation and control.

What is the "Muffle"?

The "muffle" is the furnace's inner chamber, typically made of high-temperature ceramic. It acts as a physical barrier, a protective shield that sits between the heating elements and the sample being processed.

The heating elements heat the outside of this muffle, and the muffle then radiates heat evenly into the internal chamber. This is a form of indirect heating.

Protecting the Heating Elements

During high-temperature processes, samples can release corrosive vapors and gases. In a standard furnace, these emissions would directly attack the heating elements, causing them to degrade quickly.

The muffle shields the elements from this exposure. This simple design feature dramatically increases the lifespan of the heating elements, reducing downtime and long-term maintenance costs.

Protecting the Sample

Conversely, the muffle also protects the sample. It prevents any particles or byproducts from the heating elements or fuel combustion from contaminating the material inside the chamber.

This is critical for scientific applications like gravimetric analysis or material synthesis, where even trace amounts of contamination can render results invalid.

The Resulting Advantages of a Controlled Environment

This fundamental design of isolation leads to several key performance benefits that distinguish muffle furnaces from other heating equipment.

Unmatched Temperature Uniformity

Because the entire muffle radiates heat inward, it creates an exceptionally uniform temperature zone throughout the chamber. This eliminates hot spots and ensures that the entire sample is processed at the exact same temperature.

This consistency is vital for research applications and quality control, where repeatability is essential.

High-Purity Processing

The contamination-free environment is the furnace's most valued attribute in analytical and materials science fields.

Processes like ashing (burning off organic material to measure inorganic content) rely completely on the purity of the final residue. A muffle furnace ensures that what remains is purely from the original sample.

Atmosphere Control

The sealed nature of the muffle chamber makes it ideal for controlling the internal atmosphere. This allows operators to introduce inert gases (like argon or nitrogen) to prevent oxidation or even create a vacuum for specialized processes.

Understanding the Trade-offs

No single tool is perfect for every job. The muffle furnace's advantages come with specific trade-offs when compared to other types of furnaces.

Muffle Furnace vs. Convection Oven

The primary differences are temperature and heating mechanism. A standard lab or kitchen oven uses fans for convection and rarely exceeds 300°C (572°F).

A muffle furnace uses radiant heat and can easily reach temperatures of 1200°C to 1800°C (2192°F to 3272°F), making it suitable for industrial processes like sintering, annealing, and glass manufacturing.

Muffle Furnace vs. Direct-Fired Furnace

A direct-fired furnace, where the flame or heating element is in the same chamber as the sample, can often heat up faster and may be more energy-efficient.

However, it achieves this at the cost of purity. You choose a muffle furnace when sample integrity and a contamination-free environment are more important than maximum heating speed.

Batch vs. Continuous Processing

Muffle furnaces are batch processors. You load a sample, run a cycle, and then remove it. This is ideal for labs, research, or small-scale production.

For high-throughput industrial manufacturing, a continuous furnace (like a pusher or belt furnace) that constantly moves material through a heating zone is far more efficient.

Making the Right Choice for Your Application

Selecting the right furnace depends entirely on your specific goal and priorities.

- If your primary focus is high-purity analysis or material testing: The muffle furnace is the definitive choice due to its superior contamination prevention and temperature uniformity.

- If your primary focus is extending equipment lifespan with corrosive samples: The muffle's protective design provides a clear advantage in durability and reduced maintenance.

- If your primary focus is high-volume, continuous production: A continuous system like a pusher or belt furnace will be a more suitable and efficient solution.

- If your primary focus is general heating without strict purity requirements: A simpler, direct-fired furnace may be a more cost-effective and faster option.

Ultimately, choosing a muffle furnace is a decision to prioritize control, precision, and purity above all else.

Summary Table:

| Feature | Advantage |

|---|---|

| Indirect Heating | Prevents sample contamination and protects heating elements from corrosive vapors. |

| Temperature Uniformity | Ensures even heat distribution for consistent, repeatable results. |

| Atmosphere Control | Allows use of inert gases or vacuum for oxidation prevention and specialized processes. |

| Durability | Extends heating element lifespan, reducing maintenance costs and downtime. |

Elevate your laboratory's precision with KINTEK's advanced high-temperature furnace solutions!

Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with reliable equipment like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental requirements for contamination-free heating and extended equipment life.

Ready to enhance your processes? Contact us today to discuss how our tailored solutions can benefit your specific applications!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the key role of a muffle furnace in the pretreatment of boron sludge and szaibelyite? Unlock Higher Process Efficiency

- What is the role of a muffle furnace in the synthesis of water-soluble Sr3Al2O6? Precision in SAO Production

- What substances are prohibited from being introduced into the furnace chamber? Prevent Catastrophic Failure

- What environmental conditions are critical for SiOC ceramicization? Master Precise Oxidation & Thermal Control

- How does a laboratory muffle furnace facilitate the biomass carbonization process? Achieve Precise Biochar Production