Effective muffle furnace maintenance is a systematic process, not a series of occasional fixes. The core requirements involve regular inspection of the heating elements and wiring, routine cleaning of the furnace chamber to remove oxides and debris, and performing a mandatory drying cycle before use after a long-term shutdown. These tasks are critical for ensuring operational safety, temperature accuracy, and the long-term reliability of the equipment.

Beyond a simple cleaning checklist, true maintenance is a holistic approach to preserving your furnace's integrity. It starts with a correct initial setup and extends to consistent operational protocols that protect the furnace from both wear and accidental damage.

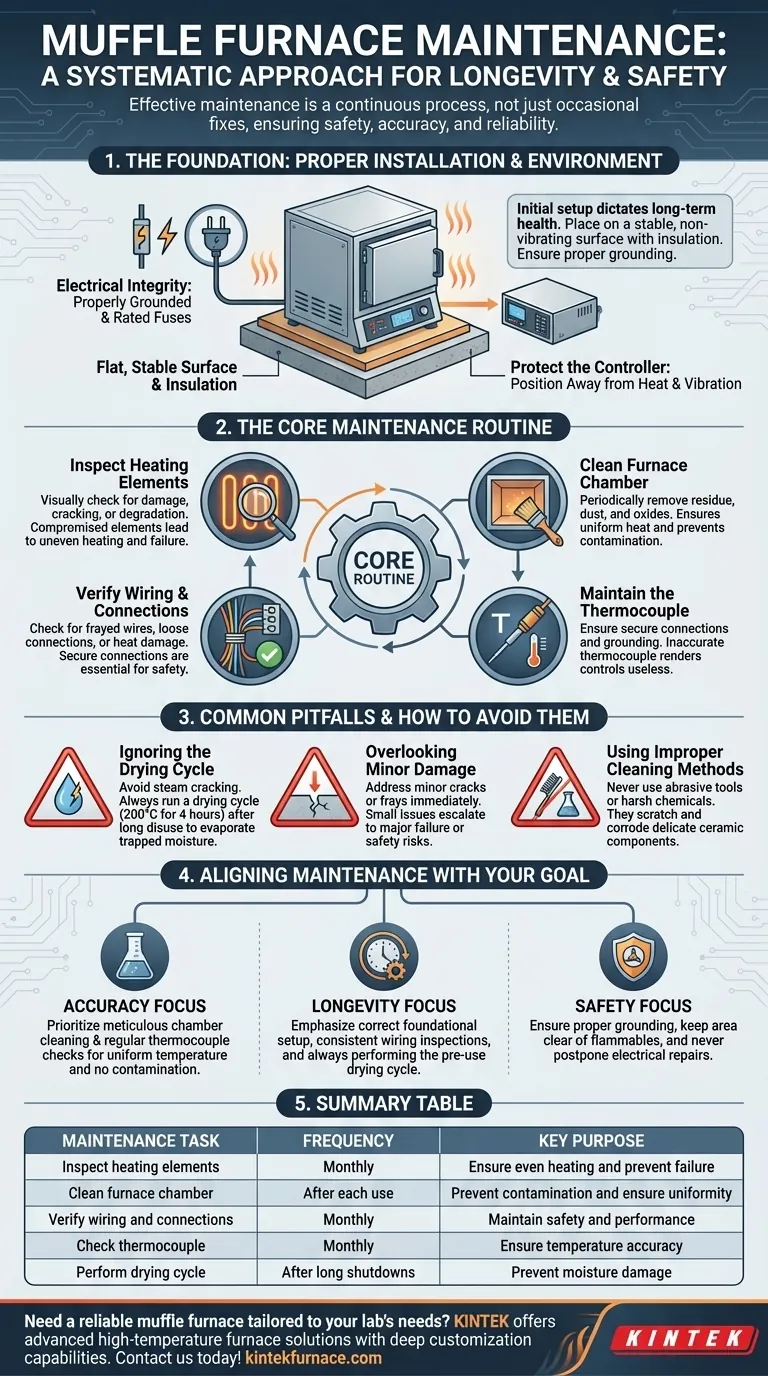

The Foundation: Proper Installation and Environment

Before any ongoing maintenance schedule is established, the initial setup dictates the furnace's long-term health and safety. Getting this right is the first step in preventative care.

Securing the Physical Placement

A muffle furnace must be placed on a perfectly flat, stable surface, such as a dedicated concrete platform. It should not be subject to any vibration.

Placing an asbestos board or similar insulating material under the furnace is advisable to protect the countertop or workbench from extreme heat damage.

Ensuring Electrical Integrity

The furnace requires appropriate plugs, sockets, and fuses rated for its power consumption. Most importantly, it must be properly grounded to prevent electrical hazards.

Protecting the Controller

The temperature controller is the brain of the operation. It should be positioned away from the furnace to avoid overheating its electronic components and must be kept free from vibration, which can disrupt its function.

The Core Maintenance Routine

This routine consists of regular checks and cleaning that should be integrated into your standard lab procedures.

Inspecting Heating Elements

Visually inspect the heating elements for any signs of damage, cracking, or degradation. A compromised element leads to uneven heating and can eventually fail completely, causing costly downtime.

Cleaning the Furnace Chamber

The internal chamber must be kept clean. Periodically and carefully remove any sample residue, dust, or oxides that have built up on the ceramic insulation. A clean chamber ensures uniform heat distribution and prevents cross-contamination of samples.

Verifying Wiring and Connections

Regularly check all wiring on both the furnace and the controller. Look for frayed wires, loose connections, or signs of heat damage. Secure connections are essential for both safety and accurate performance.

Maintaining the Thermocouple

The thermocouple provides temperature feedback to the controller. Ensure its connections are secure and it is well-grounded to prevent measurement errors. An inaccurate thermocouple renders the furnace's precision controls useless.

Common Pitfalls and How to Avoid Them

Neglecting small details can lead to significant problems. Understanding these common mistakes is key to extending the life of your furnace.

Ignoring the Drying Cycle

After a period of long-term disuse, moisture can accumulate within the furnace's insulation. Powering the furnace directly to a high temperature can cause this moisture to turn to steam, potentially cracking the ceramic chamber.

Always run a drying cycle by heating the furnace to 200°C and holding it for at least four hours to gently evaporate any trapped moisture.

Overlooking Minor Damage

Small cracks in the insulation or minor frays in wiring can seem insignificant. However, these issues can quickly escalate, leading to major component failure, inaccurate experimental results, or serious safety risks. Address any issue as soon as it is discovered.

Using Improper Cleaning Methods

Never use abrasive tools or harsh chemicals to clean the inside of the furnace. These can scratch or corrode the delicate ceramic chamber and heating elements, causing irreparable damage.

Aligning Maintenance with Your Goal

Your specific maintenance focus may shift depending on your primary objective.

- If your primary focus is experimental accuracy: Prioritize meticulous chamber cleaning and regular thermocouple checks to guarantee temperature uniformity and prevent sample contamination.

- If your primary focus is equipment longevity: Emphasize a correct foundational setup, consistent wiring inspections, and always performing the pre-use drying cycle.

- If your primary focus is laboratory safety: Ensure proper grounding, keep the area clear of all flammables, and never postpone repairs to damaged electrical components.

A consistent maintenance schedule transforms your furnace from a simple tool into a reliable and safe cornerstone of your work.

Summary Table:

| Maintenance Task | Frequency | Key Purpose |

|---|---|---|

| Inspect heating elements | Monthly | Ensure even heating and prevent failure |

| Clean furnace chamber | After each use | Prevent contamination and ensure uniformity |

| Verify wiring and connections | Monthly | Maintain safety and performance |

| Check thermocouple | Monthly | Ensure temperature accuracy |

| Perform drying cycle | After long shutdowns | Prevent moisture damage |

Need a reliable muffle furnace tailored to your lab's needs? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. With strong deep customization capabilities, we precisely meet your unique experimental requirements for enhanced safety and efficiency. Contact us today to discuss how our solutions can support your maintenance goals and boost your lab's performance!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the primary function of a muffle furnace in iron-modified activated carbon prep? Optimize Adsorption Sites

- How does the use of a 100-mesh sieve contribute to the performance consistency of magnetic chitosan carbon?

- What is the purpose of heating a precursor solution to 80 °C and 300 rpm stirring? Achieve High-Entropy Uniformity

- What key step does a Muffle Furnace perform in the determination of mineral content in Tenebrio molitor larvae?

- What is the function of a muffle furnace in SiCf/Al-Mg pretreatment? Optimize Fiber Bonding with Thermal De-sizing