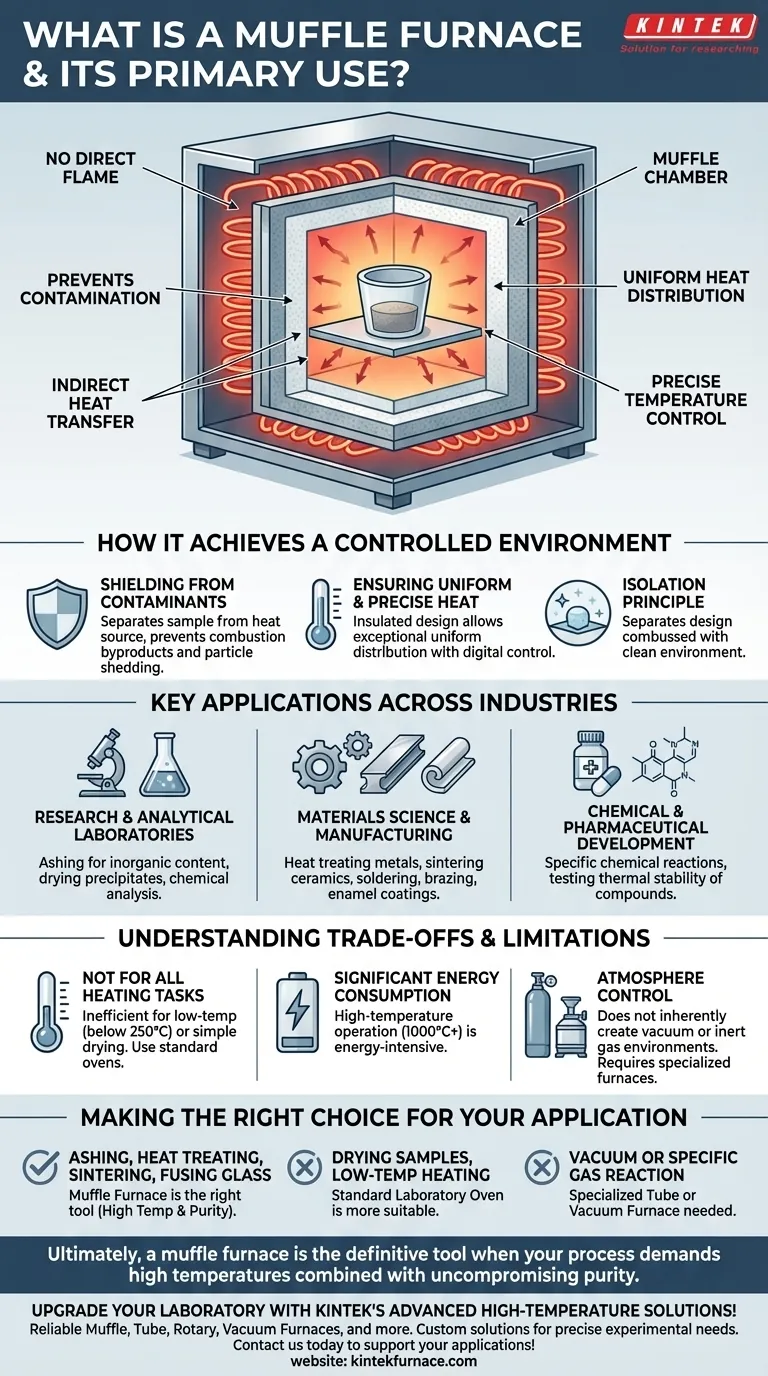

In essence, a muffle furnace is a high-temperature oven that heats materials without exposing them to direct flame or the heating elements themselves. Its primary use is to create an extremely hot and contamination-free environment, making it an indispensable tool for precise scientific testing and industrial processing where purity and temperature accuracy are critical.

The defining feature of a muffle furnace is not just its ability to reach high temperatures, but its design that isolates the sample inside a separate chamber, or "muffle." This separation is the key to preventing contamination and ensuring the uniform heat required for repeatable, high-integrity results.

How a Muffle Furnace Achieves a Controlled Environment

A muffle furnace operates on a simple but critical principle: isolation. Understanding this design is key to understanding its purpose.

The Role of the "Muffle"

The term "muffle" refers to the insulated inner chamber of the furnace, which contains the material to be heated. The heating elements, whether electric coils or gas burners, are located outside this chamber.

This design ensures that heat is transferred to the sample indirectly, typically through radiation and convection, rather than by direct contact.

Shielding from Contaminants

By separating the sample from the heat source, the furnace prevents contamination. In a gas-fired furnace, byproducts of combustion cannot enter the chamber. In an electric furnace, any particles shed from the heating elements are kept separate from the sample.

This purity is essential for processes like chemical analysis or creating high-grade materials where even trace contaminants could ruin the outcome.

Ensuring Uniform and Precise Heat

The insulated, enclosed nature of the muffle allows for exceptionally uniform heat distribution. This, combined with modern digital controllers, provides the precise temperature control necessary for sensitive processes like metallurgy and materials research.

Key Applications Across Industries

The unique capabilities of a muffle furnace make it a foundational piece of equipment in a wide range of fields.

In Research and Analytical Laboratories

Muffle furnaces are a staple for sample preparation. Common uses include ashing, where organic material is burned off at high temperatures to determine the inorganic content of a sample, such as in food science or environmental analysis.

They are also used for drying precipitates and performing chemical analyses on water, soil, or other substances.

In Materials Science and Manufacturing

Industries rely on muffle furnaces for the thermal processing of materials. This includes heat treating metals to alter their hardness and durability, sintering ceramics to fuse particles into a solid mass, and soldering or brazing components.

Other applications include creating enamel coatings, melting small batches of glass, and testing material performance under extreme heat.

In Chemical and Pharmaceutical Development

The controlled, high-purity atmosphere is ideal for performing specific chemical reactions or for testing the thermal stability of new compounds and drugs.

Understanding the Trade-offs and Limitations

While powerful, a muffle furnace is a specialized tool, and it's not always the right choice.

Not for All Heating Tasks

For simple drying or low-temperature warming (e.g., below 250°C or 500°F), a standard laboratory oven is far more energy-efficient and cost-effective. Muffle furnaces are designed specifically for high-temperature work.

Significant Energy Consumption

Reaching temperatures of 1000°C (1800°F) or higher requires a substantial amount of energy. The furnace's heavy insulation helps retain heat, but the initial ramp-up and sustained operation are energy-intensive.

Atmosphere Control

While a muffle furnace provides a clean air atmosphere, it does not inherently create a vacuum or inert gas environment. For processes that require the complete absence of oxygen, a more specialized vacuum or tube furnace is necessary.

Making the Right Choice for Your Application

Selecting the right heating equipment depends entirely on your goal.

- If your primary focus is burning off organic material (ashing): A muffle furnace is the standard and correct tool for the job.

- If your primary focus is heat-treating metals, sintering ceramics, or fusing glass: A muffle furnace provides the high temperatures and controlled environment you need.

- If your primary focus is simply drying samples or low-temperature heating: A standard laboratory oven is more suitable and energy-efficient.

- If your primary focus is a reaction that requires a vacuum or a specific gas: You will need a specialized furnace, such as a tube or vacuum furnace, designed for atmosphere control.

Ultimately, a muffle furnace is the definitive tool when your process demands high temperatures combined with uncompromising purity.

Summary Table:

| Feature | Description |

|---|---|

| Primary Use | Creates hot, contamination-free environments for precise testing and processing. |

| Key Design | Isolated inner chamber (muffle) separates sample from heat source to prevent contamination. |

| Temperature Range | Typically high temperatures (e.g., up to 1000°C or more) for demanding applications. |

| Common Applications | Ashing, heat treating, sintering, soldering, and chemical analysis in various industries. |

| Limitations | Not for low-temperature tasks; energy-intensive; lacks vacuum or inert gas control. |

Upgrade your laboratory with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse labs with reliable equipment like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise solutions for your unique experimental needs, enhancing purity, efficiency, and results. Contact us today to discuss how we can support your specific applications!

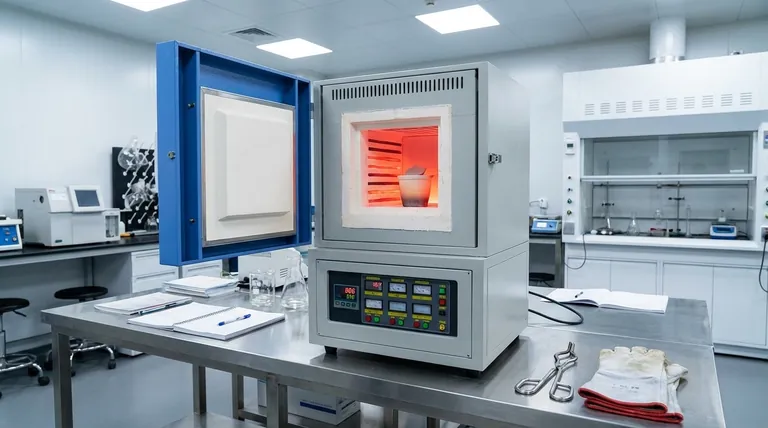

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the purpose of heating a precursor solution to 80 °C and 300 rpm stirring? Achieve High-Entropy Uniformity

- How does the use of a 100-mesh sieve contribute to the performance consistency of magnetic chitosan carbon?

- Why is re-calcination in a muffle furnace necessary for photocatalysts? Restore Efficiency via Thermal Oxidation

- What is the core function of a muffle furnace in CuO nanoparticle synthesis? Achieve Precision Calcination

- What is the function of a muffle furnace during 500°C pre-calcination? Master CeZrPAl Support Synthesis