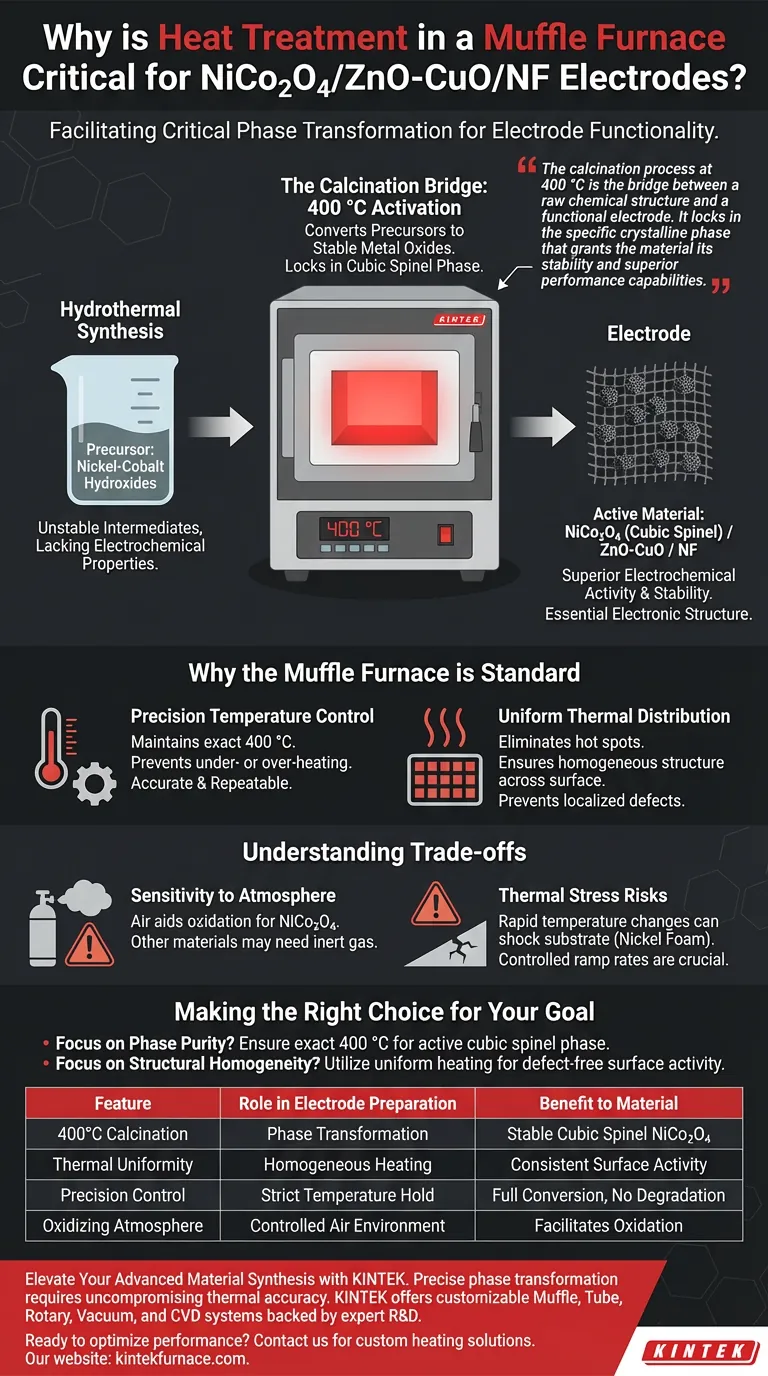

The heat treatment process facilitates a critical phase transformation necessary for electrode functionality. Specifically, this calcination step converts the intermediate hydroxide precursors formed during the hydrothermal stage into stable metal oxides, establishing the cubic spinel phase of NiCo2O4 required for high electrochemical activity.

The calcination process at 400 °C is the bridge between a raw chemical structure and a functional electrode. It locks in the specific crystalline phase that grants the material its stability and superior performance capabilities.

The Mechanics of Phase Transformation

From Precursor to Active Material

The initial hydrothermal synthesis of NiCo2O4/ZnO-CuO/NF electrodes produces intermediate compounds, primarily nickel-cobalt hydroxides.

These intermediates are chemically unstable and lack the necessary electrochemical properties for high-performance applications.

Heat treatment acts as the activation trigger, decomposing these hydroxides and converting them into their final metal oxide forms.

Establishing the Crystal Structure

The primary goal of the 400 °C calcination is to achieve a specific cubic spinel phase in the NiCo2O4 component.

This crystalline arrangement is not accidental; it is strictly required to ensure the material possesses the correct electronic structure.

Without this specific phase transformation, the electrode would fail to exhibit the superior electrochemical activity required for its intended application.

Why the Muffle Furnace is the Standard

Precision Temperature Control

Achieving the cubic spinel phase requires holding the material at exactly 400 °C.

Muffle furnaces provide advanced temperature control systems that allow for accurate, repeatable heating within this narrow range.

This precision prevents partial conversion (under-heating) or structural degradation (over-heating).

Uniform Thermal Distribution

A critical advantage of the muffle furnace is its ability to ensure uniform heating throughout the chamber.

This design eliminates "hot spots" that could cause uneven phase changes across the electrode surface.

By preventing thermal gradients, the furnace ensures the entire electrode possesses a homogeneous structure free of localized defects.

Understanding the Trade-offs

Sensitivity to Atmosphere

While muffle furnaces are excellent for calcination (heating in air), the atmosphere must be carefully managed based on the material goals.

For metal oxides like NiCo2O4, an air environment aids oxidation, but other materials might require inert gas to prevent unwanted reactions.

Thermal Stress Risks

Rapid heating or cooling within the furnace can introduce thermal shock to the electrode substrate (Nickel Foam).

While the furnace allows for high temperatures, the ramp rates must be controlled to prevent the active material from delaminating from the conductive support.

Making the Right Choice for Your Goal

To maximize the performance of your NiCo2O4/ZnO-CuO/NF electrodes, consider the following parameters during heat treatment:

- If your primary focus is Phase Purity: Ensure the furnace is calibrated to maintain exactly 400 °C, as this specific temperature drives the conversion to the active cubic spinel phase.

- If your primary focus is Structural Homogeneity: Utilize the uniform heating capabilities of the muffle furnace to eliminate defects and ensure the entire electrode surface contributes to electrochemical activity.

By precisely controlling the thermal environment, you transform unstable precursors into a robust, high-performance electrochemical tool.

Summary Table:

| Feature | Role in Electrode Preparation | Benefit to Material |

|---|---|---|

| 400°C Calcination | Phase Transformation | Converts hydroxides into stable cubic spinel NiCo2O4 |

| Thermal Uniformity | Homogeneous Heating | Prevents localized defects and ensures consistent surface activity |

| Precision Control | Strict Temperature Hold | Guarantees full precursor conversion without structural degradation |

| Oxidizing Atmosphere | Controlled Air Environment | Facilitates the necessary oxidation for metal oxide formation |

Elevate Your Advanced Material Synthesis with KINTEK

Precise phase transformation is the difference between a raw chemical and a high-performance electrode. At KINTEK, we understand that achieving the perfect cubic spinel phase requires uncompromising thermal accuracy. Backed by expert R&D and world-class manufacturing, we provide a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems—all fully customizable to meet your specific research or production needs.

Ready to optimize your NiCo2O4/ZnO-CuO/NF electrode performance? Contact us today to find your custom heating solution and ensure every calcination step delivers superior stability and electrochemical activity.

Visual Guide

References

- Muhammad Ali Bhatti, Zafar Hussain Ibupoto. Advanced NiCo2O4 /ZnO-CuO/NF composite for high-performance asymmetric supercapacitor and efficient oxygen evolution reaction applications. DOI: 10.1007/s42114-025-01238-9

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- How does convective heat transfer in a hot air oven affect iron ore briquettes? Expert Guide to Drying Quality

- What role does a high-temperature muffle furnace play in the component analysis of Moringa oleifera seeds?

- How does a muffle furnace compare to a vacuum furnace? Choose the Right Heat Treatment for Your Materials

- How do crucible furnaces provide cost-effectiveness? Balancing Low Upfront Cost with Operational Efficiency

- What is the function of a laboratory muffle furnace in treating LNMO precursors? Ensure High-Purity Material Synthesis

- What types of workpieces are suitable for box type high-temperature resistance furnaces? Versatile Solutions for Metals, Ceramics, and More

- What temperature range can a muffle furnace operate within? Unlock High Heat and Precision for Your Lab

- Why is a secondary annealing treatment in a muffle furnace necessary for coated ceramic sensor components?