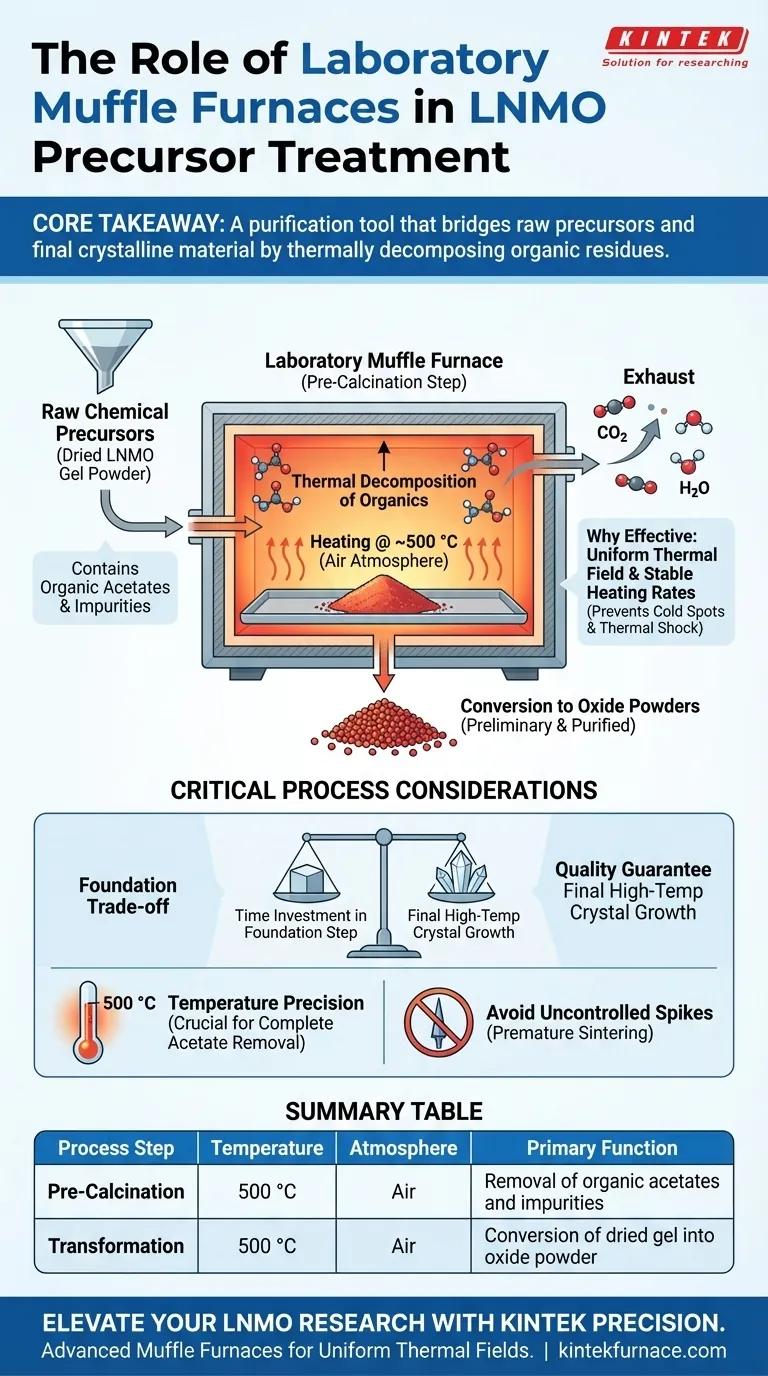

The primary function of a laboratory muffle furnace in the treatment of LiNi0.5Mn1.5O4 (LNMO) precursors is to perform a critical pre-calcination step. By heating dried LNMO gel powder to approximately 500 °C in an air atmosphere, the furnace facilitates the removal of unwanted organic components.

Core Takeaway The muffle furnace acts as a purification tool that bridges the gap between raw chemical precursors and the final crystalline material. Its role is to thermally decompose organic residues, such as acetates, converting the gel into a preliminary oxide powder ready for high-temperature crystal growth.

The Mechanism of Pre-Calcination

Thermal Decomposition of Organics

The muffle furnace provides the thermal energy required to break down organic materials found in the dried LNMO gel.

Specifically, it targets residual acetates and other organic components that remain from the initial synthesis steps. By maintaining a temperature of 500 °C, the furnace ensures these impurities are effectively burned off.

Conversion to Oxide Powders

As the organic components are removed, the material undergoes a chemical transformation.

The furnace converts the organic precursors into preliminary oxide powders. This conversion is not the final stage of synthesis, but it is a mandatory prerequisite to establish the chemical purity required for the final product.

Atmosphere Management

The process relies on the presence of an air atmosphere within the furnace chamber.

The oxygen in the air assists in the combustion and removal of the organic carbon-based residues, ensuring the resulting powder is free of contaminants that could inhibit future processing.

Why the Muffle Furnace is Effective

Uniform Thermal Field

While the specific temperature for LNMO is 500 °C, the muffle furnace is valuable because of its ability to create a uniform thermal field.

This ensures that the entire batch of powder receives the same heat treatment, preventing "cold spots" where organic residues might survive.

Stable Heating Rates

Muffle furnaces allow for controlled ramp-up times (stable heating rates).

This controlled approach prevents thermal shock and allows for the smooth, gradual decomposition of volatiles, which results in a more structurally uniform precursor compared to rapid, uncontrolled heating.

Critical Process Considerations

The "Foundation" Trade-off

It is crucial to understand that the product emerging from the muffle furnace at 500 °C is not the final active material.

The trade-off here is a multi-step process: you must invest time in this intermediate "foundation" step to guarantee quality later. Skipping or rushing this stage to get to high-temperature sintering immediately will likely result in impurities that ruin the crystal structure.

Temperature Precision

The effectiveness of this process is strictly bound to temperature accuracy.

If the temperature is significantly below 500 °C, residual acetates may remain, contaminating the final product. Conversely, uncontrolled temperature spikes could trigger premature sintering before the organics are fully evacuated.

Making the Right Choice for Your Goal

To maximize the quality of your LNMO synthesis, apply the following principles:

- If your primary focus is Material Purity: Ensure the furnace is calibrated to hold exactly 500 °C in an air atmosphere to guarantee the complete removal of acetates.

- If your primary focus is Crystal Growth: Treat the muffle furnace stage as a foundational preparation step, recognizing that this creates the oxide precursor necessary for successful high-temperature crystallization later.

The muffle furnace ensures that your raw gel is stripped of organic noise, leaving behind a clean oxide canvas for the final crystal structure.

Summary Table:

| Process Step | Temperature | Atmosphere | Primary Function |

|---|---|---|---|

| Pre-Calcination | 500 °C | Air | Removal of organic acetates and impurities |

| Transformation | 500 °C | Air | Conversion of dried gel into oxide powder |

| Thermal Control | Variable | Uniform | Ensures stable decomposition of volatiles |

Elevate Your LNMO Research with KINTEK Precision

High-performance battery materials like LNMO demand absolute purity and thermal precision. KINTEK’s advanced laboratory muffle furnaces provide the uniform thermal fields and stable heating rates essential for perfect pre-calcination and organic decomposition.

Backed by expert R&D and world-class manufacturing, we offer a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems—all fully customizable to meet your specific lab requirements. Don't compromise your crystal growth with inconsistent heating.

Ready to optimize your material synthesis? Contact KINTEK today for a custom solution!

Visual Guide

References

- Jong‐Won Lim, Kyung‐Won Park. Enhanced Electrochemical Stability of Solid‐State Electrolyte‐Coated High‐Voltage <scp>L</scp>i<scp>N</scp>i<sub>0.5</sub><scp>M</scp>n<sub>1.5</sub><scp>O</scp><sub>4</sub> Cathodes in Li‐Ion Batteries. DOI: 10.1002/eem2.70025

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What are the safety precautions when connecting power to a new muffle furnace? Ensure Safe Setup for Your Lab

- How are muffle furnaces utilized in high-temperature sintering within the pharmaceutical industry? Unlock Precision in Drug Delivery and Implants

- What process conditions does a muffle furnace provide for rGO reduction? Master Graphene Oxide Thermal Processing

- What factors should be prioritized when selecting a muffle furnace for laboratory use? Ensure Precision and Safety

- What electrical safety checks should be performed before operating a benchtop furnace? Ensure Safe Operation and Prevent Hazards

- What physical principles govern muffle furnace operation? Master Energy, Heat Transfer, and Control

- What design features enhance the versatility of a box furnace? Boost Your Lab's Thermal Processing Capabilities

- How is a box resistance furnace or muffle furnace utilized when processing BCZT gel? Expert Powder Synthesis Guide