Before energizing any high-temperature equipment, a series of disciplined electrical safety checks is mandatory. You must physically inspect all electrical wiring for damage, verify the integrity of plugs and connections, and confirm the furnace is properly grounded. These steps are the absolute minimum required to mitigate the immediate risks of electrical shock and fire.

Your core responsibility is not just to check a list, but to cultivate a mindset where electrical safety is a non-negotiable prerequisite for operation. A benchtop furnace combines high-power electricity with extreme heat, creating a uniquely hazardous environment where minor oversights can lead to catastrophic failure.

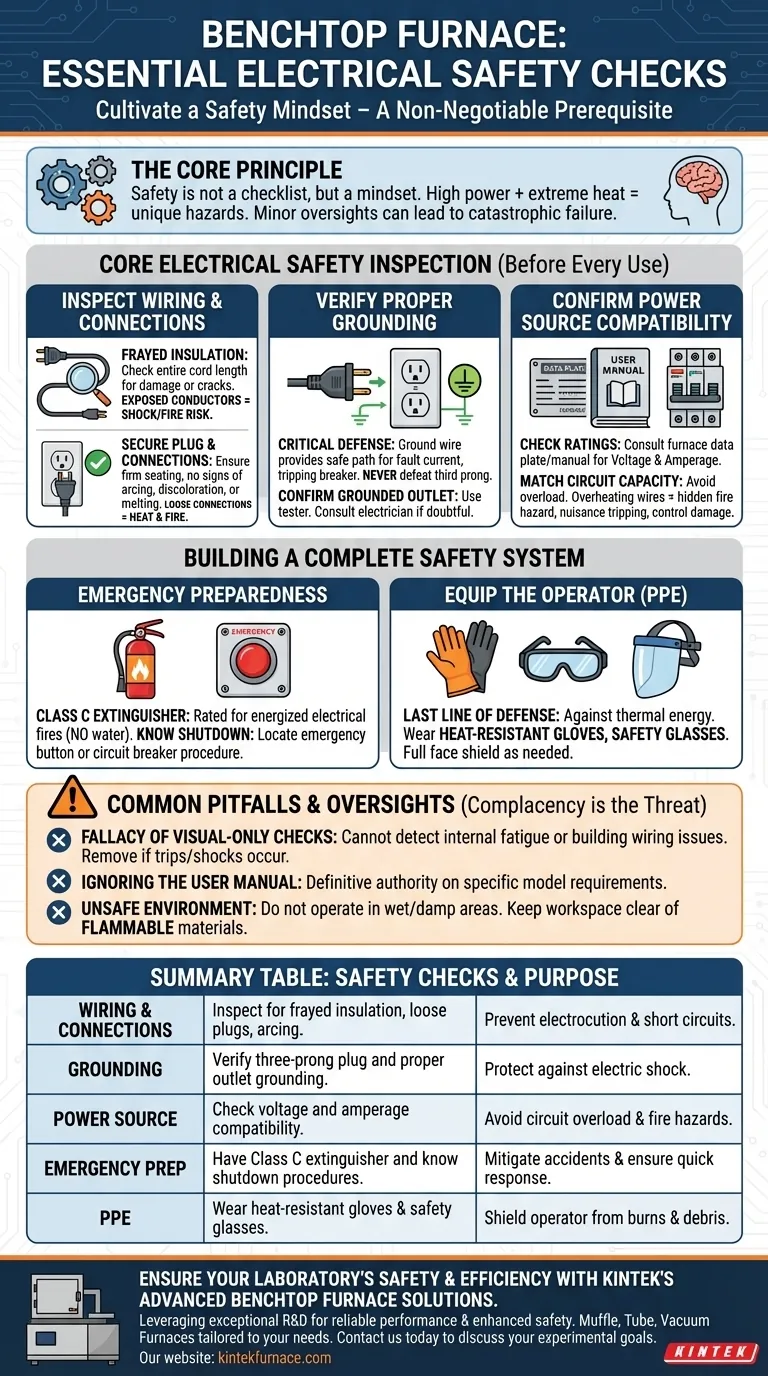

The Core Electrical Safety Inspection

Before every single use, a physical inspection of the furnace's electrical system must be performed. This is not a task to be rushed or delegated without verification.

Inspect All Wiring and Connections

Examine the entire length of the power cord. Look for any signs of frayed insulation, cracks, or pinch points. Damaged wiring exposes live conductors, creating a severe risk of electrocution or a short circuit that can ignite a fire.

Ensure the plug is firmly seated in the outlet. Check that the connection point on the furnace itself is secure and shows no signs of arcing, such as discoloration or melting. Loose connections generate heat and are a primary cause of electrical fires.

Verify Proper Grounding

Proper grounding is your most critical defense against electric shock. The ground wire provides a safe path for electrical current to flow in the event of an internal fault, tripping the circuit breaker instead of passing through your body.

Never use an adapter to defeat the third grounding prong on a plug. Confirm that your outlet is a properly grounded, three-hole receptacle. If you have any doubt about the integrity of your building's wiring, consult a qualified electrician.

Confirm Power Source Compatibility

You must confirm that the circuit you are using can handle the furnace's power requirements. Check the furnace's data plate or user manual for its specific voltage and amperage rating.

Plugging a high-draw appliance into an underrated circuit can lead to overheating wires within the walls, creating a hidden fire hazard. It can also cause nuisance tripping of the breaker or damage to the furnace's sensitive electronic controls.

Building a Complete Safety System

A safe electrical connection is only one part of a larger system. Your awareness of the environment and preparedness for failure are just as critical.

Prepare for Emergency Scenarios

Always have a Class C fire extinguisher within immediate reach. This type is specifically rated for energized electrical fires. Water-based extinguishers must never be used, as they can conduct electricity and worsen the situation.

Ensure a smoke detector is installed and functional in the area. Crucially, every operator must know the exact location of the emergency shutdown button or the procedure for cutting power at the circuit breaker panel.

Equip the Operator

Personal Protective Equipment (PPE) is your last line of defense. Even if no electrical fault occurs, the furnace is a source of intense thermal energy.

Always wear heat-resistant gloves and safety glasses or goggles to protect against burns and debris. For some operations, a full face shield and other protective clothing may be necessary as specified by your lab's safety protocols.

Common Pitfalls and Oversights

Complacency is the greatest threat to safety. A furnace that worked yesterday is not guaranteed to be safe today.

The Fallacy of Visual-Only Checks

While a visual inspection is essential, it cannot detect internal wire fatigue or a failing ground connection within the building's wiring. If a furnace repeatedly trips a breaker or gives even a minor static shock, it must be removed from service immediately for professional inspection.

Ignoring the User Manual

The manufacturer's user manual is the definitive authority on your specific furnace model. It contains precise information on power requirements, installation, and safety procedures. Assuming one furnace works like another is a dangerous shortcut.

Creating an Unsafe Environment

Do not operate the furnace in a wet or damp area. Keep the surrounding workspace clear of all flammable materials, including solvents, paper, and plastics. A clear workspace is a safe workspace.

Making the Right Choice for Your Goal

Before every use, run through this mental checklist based on your primary concern.

- If your primary focus is preventing electric shock: Verify the grounding prong is intact and connected to a proper outlet, and meticulously inspect the power cord for any insulation damage.

- If your primary focus is preventing fire: Ensure the circuit's amperage is sufficient for the furnace, confirm all connections are tight, and keep the area clear of all combustibles.

- If your primary focus is total operator safety: Integrate all electrical and environmental checks with the mandatory use of PPE and a clear understanding of the emergency shutdown procedure.

Treating every startup as the first startup is the mark of a true professional.

Summary Table:

| Safety Check | Key Steps | Purpose |

|---|---|---|

| Wiring and Connections | Inspect for frayed insulation, loose plugs, and arcing signs | Prevent electrocution and short circuits |

| Grounding | Verify three-prong plug and proper outlet grounding | Protect against electric shock |

| Power Source | Check voltage and amperage compatibility | Avoid circuit overload and fire hazards |

| Emergency Preparedness | Have Class C fire extinguisher and know shutdown procedures | Mitigate accidents and ensure quick response |

| PPE | Wear heat-resistant gloves and safety glasses | Shield operator from burns and debris |

Ensure your laboratory's safety and efficiency with KINTEK's advanced benchtop furnace solutions. Leveraging exceptional R&D and in-house manufacturing, we provide high-temperature furnaces like Muffle, Tube, and Vacuum Furnaces, tailored to your unique needs with deep customization. Our products are designed for reliable performance and enhanced safety. Contact us today to discuss how we can support your experimental goals and deliver precise, durable solutions for your lab.

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What environmental conditions are critical for SiOC ceramicization? Master Precise Oxidation & Thermal Control

- What is the key role of a muffle furnace in the pretreatment of boron sludge and szaibelyite? Unlock Higher Process Efficiency

- What is the role of a muffle furnace in the synthesis of water-soluble Sr3Al2O6? Precision in SAO Production

- What substances are prohibited from being introduced into the furnace chamber? Prevent Catastrophic Failure

- What role does a muffle furnace play in the preparation of MgO support materials? Master Catalyst Activation