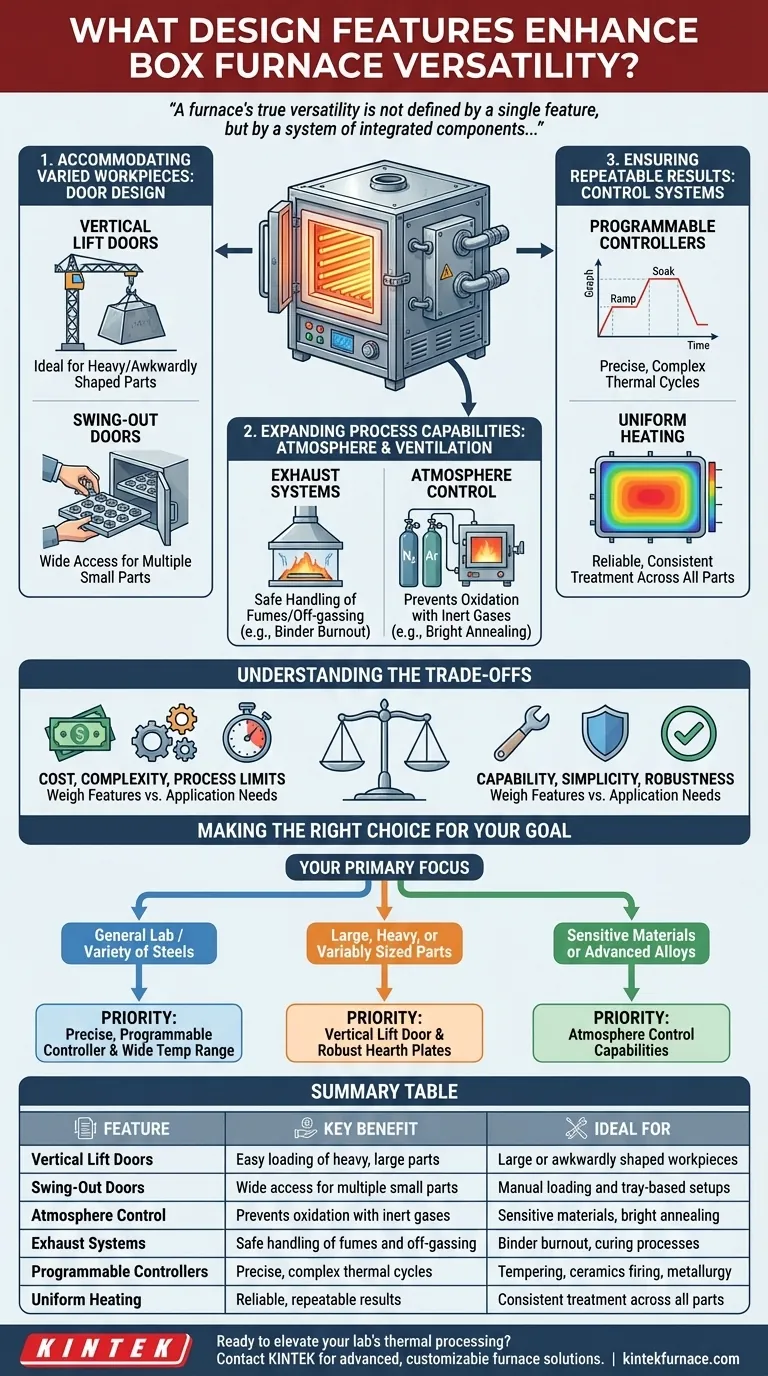

At its core, a box furnace’s versatility comes from design features that expand its operational window. Key enhancements include adaptable door mechanisms for various part sizes, sophisticated control systems for precise thermal profiles, and atmosphere or exhaust systems that enable a wider range of material processing applications.

A furnace's true versatility is not defined by a single feature, but by a system of integrated components that allow it to handle diverse materials, part geometries, and complex thermal processes safely and repeatably.

Core Features Driving Versatility

A versatile box furnace is a workhorse capable of more than just basic heating. The following features are critical in transforming a simple heated box into a multi-purpose thermal processing tool.

Accommodating Varied Workpieces: Door Design

The door is the primary physical interface with the furnace. Its design directly impacts what you can process.

Vertical lift doors are ideal for heavy or awkwardly shaped parts, often allowing for loading with a forklift or overhead crane. This maximizes the usable chamber volume for large items.

Swing-out doors (also known as swing-away or barn doors) provide wide-open access to the chamber, which is excellent for loading multiple smaller parts by hand or on trays.

Expanding Process Capabilities: Atmosphere and Ventilation

What happens inside the chamber is as important as the heat itself. Controlling the internal atmosphere is a major factor in versatility.

An exhaust system, such as a fume hood, is essential for safety and process integrity when materials off-gas volatile compounds. This enables processes like binder burnout, curing, or heat-treating materials that produce fumes.

Atmosphere control is a significant upgrade that dramatically expands a furnace's use. By introducing inert gases like nitrogen or argon, you can prevent oxidation on sensitive metals. This is critical for applications like bright annealing or sintering non-ferrous metals.

Ensuring Repeatable Results: Control Systems

A furnace is only as good as its ability to follow a recipe. The control system dictates the precision and complexity of the thermal cycles you can run.

A programmable controller that allows for multiple ramp/soak segments is a necessity for versatility. This enables complex cycles required for tempering, advanced ceramics firing, or specific metallurgical processes.

Precision and uniformity are byproducts of a good control system paired with well-designed heating elements. A furnace that provides uniform heat throughout the chamber ensures that all parts, regardless of placement, receive the same treatment, making results reliable and repeatable.

Understanding the Trade-offs

While advanced features increase versatility, they also introduce practical trade-offs that must be considered.

Cost vs. Capability

Each feature adds to the initial investment. A furnace with inert atmosphere capabilities and a vertical lift door will be significantly more expensive than a basic air-atmosphere unit with a swing door.

You must weigh the cost of these features against the tangible need for them in your planned applications. Paying for versatility you will never use is an inefficient use of capital.

Simplicity vs. Complexity

More advanced systems require more sophisticated operation and maintenance. An atmosphere control system involves gas lines, flow meters, and safety interlocks that a simple furnace does not have.

Consider your team's technical skill and the maintenance resources available. For a single, unchanging process, a simpler, more robust furnace may be a better long-term choice than a complex one.

Process Limitations

Even a versatile box furnace has limits. A standard furnace operates in an air atmosphere, which is oxidizing. Without specific atmosphere control features, it is unsuitable for processes that require an oxygen-free environment.

Similarly, while many furnaces can reach high temperatures, the rate of heating and cooling is also a critical parameter. If your process requires extremely rapid quenching, a box furnace may not be the appropriate equipment.

Making the Right Choice for Your Goal

Select features that align directly with your primary operational requirements, both now and in the foreseeable future.

- If your primary focus is general-purpose lab work or heat treating a variety of steels: Prioritize a precise, programmable controller and a wide temperature range.

- If your primary focus is processing large, heavy, or variably sized parts: Emphasize the door design (likely vertical lift) and robust hearth plates to handle the load.

- If your primary focus is processing sensitive materials or advanced alloys: Invest in atmosphere control capabilities to prevent oxidation and ensure specific material properties.

Ultimately, choosing the right furnace is about matching the machine's capabilities to your process demands.

Summary Table:

| Feature | Key Benefit | Ideal For |

|---|---|---|

| Vertical Lift Doors | Easy loading of heavy, large parts | Large or awkwardly shaped workpieces |

| Swing-Out Doors | Wide access for multiple small parts | Manual loading and tray-based setups |

| Atmosphere Control | Prevents oxidation with inert gases | Sensitive materials, bright annealing |

| Exhaust Systems | Safe handling of fumes and off-gassing | Binder burnout, curing processes |

| Programmable Controllers | Precise, complex thermal cycles | Tempering, ceramics firing, metallurgy |

| Uniform Heating | Reliable, repeatable results | Consistent treatment across all parts |

Ready to elevate your lab's thermal processing? At KINTEK, we specialize in advanced high-temperature furnace solutions tailored to your unique needs. Leveraging our exceptional R&D and in-house manufacturing, we offer a diverse product line—including Box, Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems—with strong deep customization capabilities to precisely meet your experimental requirements. Whether you need versatile door designs, precise control systems, or atmosphere options, we can help you achieve superior results. Contact us today to discuss how our furnaces can enhance your efficiency and expand your process capabilities!

Visual Guide

Related Products

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What role does a high-temperature box resistance furnace play in sintering? Mastering Electrolyte Tube Densification

- How is a laboratory muffle furnace utilized during the debinding stage of HAp green bodies? Precision Thermal Control

- How is a muffle furnace utilized for AlN crystal post-processing? Optimize Surface Purity via Staged Oxidation

- Why is a box muffle furnace used for the 800°C annealing of titanium LMD samples? Optimize Your Material Performance

- Why is a laboratory high-temperature box furnace essential for KNN ceramic powders? Mastering Solid-State Synthesis