In the pharmaceutical industry, muffle furnaces are primarily utilized for high-temperature sintering to create solid, porous structures from powdered materials without melting them. This process is essential for manufacturing advanced drug delivery systems and medical implants, where the furnace’s ability to provide a precisely controlled and uniform heating environment ensures consistent product quality and performance.

The true value of a muffle furnace in pharmaceuticals extends beyond any single task. It is a fundamental tool for any process requiring an exceptionally pure, precisely controlled, high-temperature environment, from creating new materials via sintering to verifying product quality through ashing.

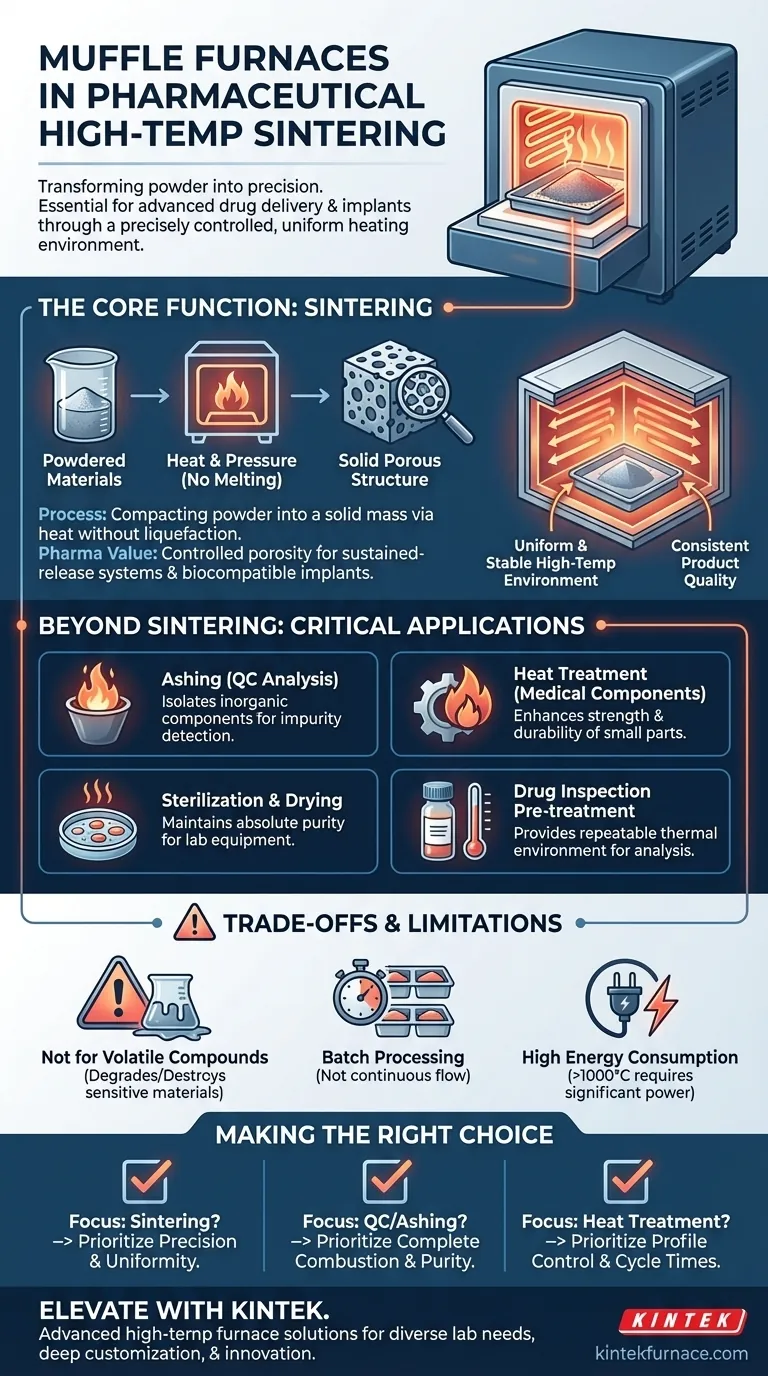

The Core Function: Creating Advanced Materials via Sintering

Sintering is a sophisticated thermal process that lies at the heart of modern material science, including advanced pharmaceutical development. A muffle furnace provides the ideal environment to execute this process with the required precision.

What is Sintering?

Sintering is the process of compacting and forming a solid mass of material by heat and pressure without melting it to the point of liquefaction. Powdered materials are heated to a high temperature, causing the particles to bond and fuse together.

Why Sintering Matters in Pharmaceuticals

This technique is used to create components with controlled porosity, which is critical for applications like sustained-release drug delivery systems or biocompatible implants. The resulting structure's physical properties are directly tied to the consistency of the sintering process.

The Muffle Furnace's Role

A muffle furnace provides the uniform and stable high-temperature environment necessary for consistent sintering. Its design ensures that the material is heated evenly, preventing structural defects and guaranteeing that each batch has the same physical characteristics, a non-negotiable requirement in pharmaceutical manufacturing.

Beyond Sintering: Other Critical Applications in Pharma

While sintering is a key application, the muffle furnace's utility in the pharmaceutical industry is broad. Its core function is to provide clean, controlled heat for various analytical and preparatory processes.

Analytical Sample Preparation (Ashing)

Muffle furnaces are widely used for ashing, a process that involves burning off all organic substances in a sample to isolate the inorganic components. This is a crucial step in quality control to determine the mineral content or detect inorganic impurities in raw materials or final products.

Drug Inspection and Quality Control

For many analytical tests, medical or drug samples must be pre-treated at a specific high temperature. A muffle furnace provides this repeatable thermal environment, ensuring that sample preparation does not introduce variables that could skew analytical results.

Heat Treatment of Medical Components

The furnace is also used for the heat treatment of small metal parts used in medical devices. Processes like annealing or normalizing alter the metal's physical properties, enhancing its strength, durability, and performance to meet strict medical standards.

Sterilization and Drying

At a more basic level, the high, dry heat of a muffle furnace can be used for the sterilization of certain laboratory equipment or the drying of chemical compounds where absolute purity must be maintained.

Understanding the Trade-offs and Limitations

While incredibly useful, muffle furnaces are specialized tools with specific operational boundaries that are important to recognize.

Not Suitable for Volatile or Sensitive Compounds

The intense heat will degrade or destroy many organic and biologically active compounds. Muffle furnaces are only appropriate for materials that are thermally stable at the target temperature.

Primarily for Batch Processing

Muffle furnaces are designed for processing discrete, often small, batches of material. They are not suited for continuous manufacturing workflows, where materials flow constantly through a process line.

High Energy Consumption

Achieving and maintaining temperatures that can exceed 1000°C requires a significant amount of electrical energy. This operational cost is a practical consideration for any lab or manufacturing facility.

Making the Right Choice for Your Goal

Selecting and utilizing a muffle furnace effectively depends entirely on the intended application. Your process requirements should dictate your operational focus.

- If your primary focus is creating novel drug delivery systems or implants: Prioritize a furnace with exceptionally precise temperature ramping and control to ensure consistent and uniform sintering.

- If your primary focus is quality control and analysis: Emphasize a furnace that guarantees complete combustion for ashing and maintains a contaminant-free chamber for accurate sample pretreatment.

- If your primary focus is modifying materials for medical devices: Select a furnace capable of achieving specific temperature profiles and cycle times required for effective metallurgical heat treatment.

Ultimately, the muffle furnace serves as an indispensable tool for ensuring quality, safety, and innovation in high-temperature pharmaceutical processes.

Summary Table:

| Application | Key Benefits |

|---|---|

| Sintering | Creates porous structures for drug delivery and implants with uniform heating |

| Ashing | Isolates inorganic components for quality control and impurity detection |

| Heat Treatment | Enhances strength and durability of medical device components |

| Sterilization/Drying | Maintains purity for lab equipment and compounds |

Elevate your pharmaceutical processes with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with reliable tools like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your unique experimental needs, whether for sintering drug delivery systems, quality control, or medical device heat treatment. Contact us today to discuss how our tailored solutions can enhance your efficiency and innovation!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the key role of a muffle furnace in the pretreatment of boron sludge and szaibelyite? Unlock Higher Process Efficiency

- What is the primary function of a muffle furnace for BaTiO3? Master High-Temp Calcination for Ceramic Synthesis

- What is the role of a muffle furnace in the synthesis of water-soluble Sr3Al2O6? Precision in SAO Production

- What substances are prohibited from being introduced into the furnace chamber? Prevent Catastrophic Failure

- What role does a muffle furnace play in the preparation of MgO support materials? Master Catalyst Activation