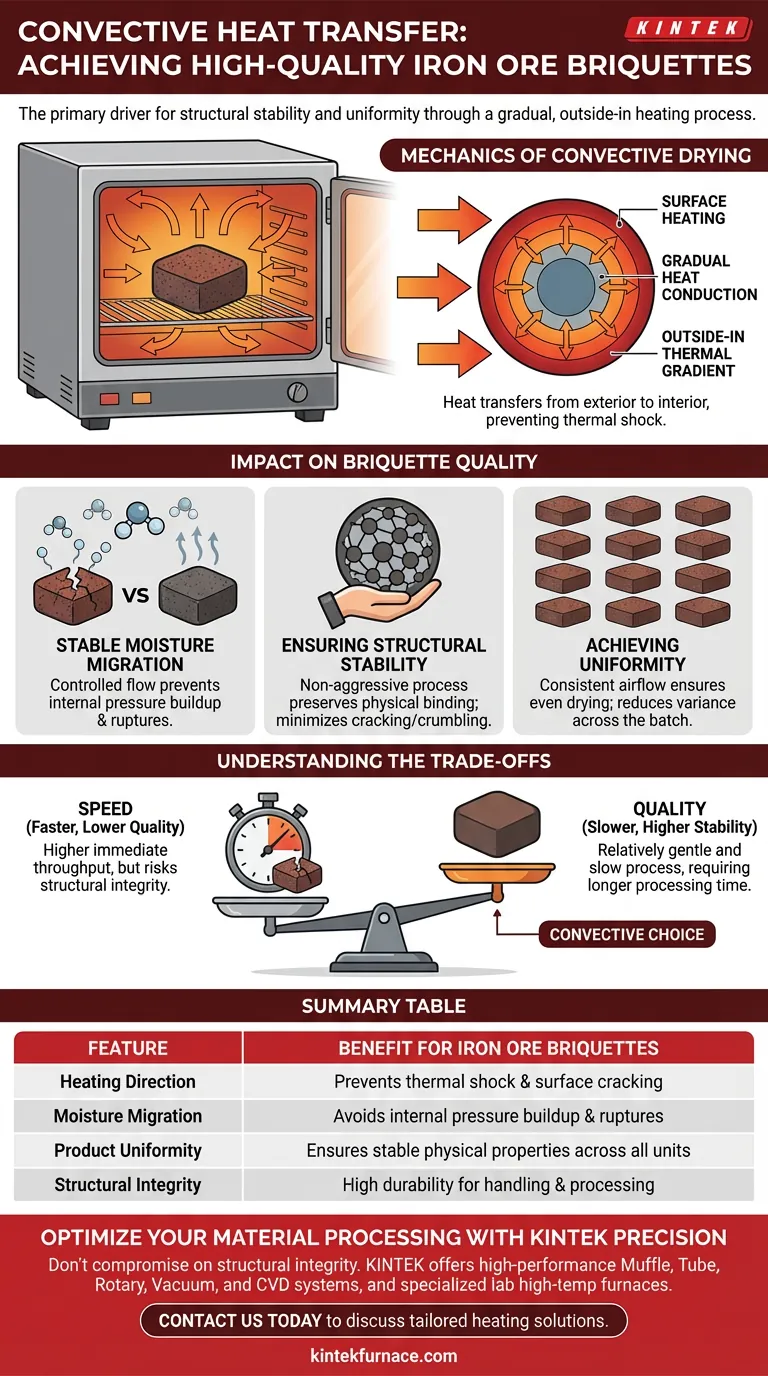

Convective heat transfer in a hot air oven is the primary driver for achieving high structural stability and uniformity in iron ore briquettes. By utilizing a gradual, outside-in heating process, this method ensures moisture is removed in a controlled manner, preventing the internal stresses that often compromise the physical integrity of the briquette.

The "outside-in" nature of convective heating creates a gentle thermal gradient, allowing for stable moisture migration. This approach prioritizes physical integrity over speed, resulting in a final product with superior structural stability.

The Mechanics of Convective Drying

The Outside-In Thermal Gradient

In a hot air oven, thermal energy is transferred via convection to the exterior of the briquette first. Heat then conducts gradually from the surface to the center of the material.

Gradual Heat Conduction

This process creates a distinctive outside-in drying profile. Unlike volumetric heating methods, the temperature rise is deliberate and layered, avoiding sudden thermal shocks to the material.

Impact on Briquette Quality

Facilitating Stable Moisture Migration

The gentle heating rate allows moisture to move from the core to the surface in a predictable, controlled flow. This stable moisture migration prevents the rapid buildup of internal steam pressure that can rupture the briquette.

Ensuring Structural Stability

Because the drying process is non-aggressive, the physical binding of the iron ore is preserved. The result is a dried briquette with high structural stability, minimizing the risk of cracking or crumbling during subsequent handling.

Achieving Uniformity

The consistent airflow inherent in convective heating ensures that the drying effect is applied evenly across the material. This leads to uniform quality throughout the entire batch, reducing the variance between individual briquettes.

Understanding the Trade-offs

The Speed vs. Quality Balance

The primary characteristic of this method is that it is relatively gentle and slow. While this ensures a high-quality output, it inherently requires a longer processing cycle than more aggressive drying techniques.

Throughput Implications

Operators must recognize that the mechanism protecting the briquette's structure imposes a limit on drying speed. Prioritizing structural stability via convection often means accepting lower immediate throughput.

Making the Right Choice for Your Goal

When evaluating drying methods for iron ore briquettes, the choice depends heavily on your tolerance for processing time versus your requirement for physical durability.

- If your primary focus is maximizing physical strength: Rely on the convective hot air oven to deliver the gentle, outside-in heat required to preserve structural integrity.

- If your primary focus is product consistency: Leverage the stable airflow of convective heating to ensure uniform quality across every briquette in the batch.

Convective drying remains the definitive choice for operations where the physical quality of the briquette is non-negotiable.

Summary Table:

| Feature | Convective Drying Impact | Benefit for Iron Ore Briquettes |

|---|---|---|

| Heating Direction | Outside-in thermal gradient | Prevents thermal shock and surface cracking |

| Moisture Migration | Gradual and controlled flow | Avoids internal pressure buildup and ruptures |

| Product Uniformity | Consistent batch airflow | Ensures stable physical properties across all units |

| Structural Integrity | Non-aggressive heat conduction | High durability for handling and processing |

Optimize Your Material Processing with KINTEK Precision

Don't compromise on the structural integrity of your iron ore briquettes. At KINTEK, we understand that high-quality results require precise thermal control. Backed by expert R&D and world-class manufacturing, we provide high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems, along with specialized lab high-temp furnaces—all fully customizable to meet your specific drying and sintering needs.

Ready to enhance your lab's efficiency and product consistency? Contact us today to discuss how our advanced heating solutions can be tailored to your unique industrial requirements!

Visual Guide

References

- Rishi Sharma, D. S. Nimaje. Study of drying kinetics and moisture diffusivity in iron ore briquettes after using different drying techniques. DOI: 10.2298/jmmb240910010s

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1200℃ Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Small Rotary Kiln Calciner

People Also Ask

- What is the function of a muffle furnace in 550°C NiCuCe catalyst calcination? Master Your Thermal Transformation

- What is the function of a muffle furnace in NiFe2O4/biochar prep? Optimize Your Composite Synthesis

- What are the key applications of box type resistance furnaces? Versatile Heating for Metals, Ceramics, and More

- What are the key advantages of using muffle furnaces? Achieve Clean, Uniform, and High-Temp Heating

- What role does a laboratory muffle furnace play in the industrial analysis of plastic waste? Optimizing Pyrolysis Yield

- How does the furnace atmosphere contribute to the function of a muffle furnace? Unlock Precision in Material Processing

- How does the airflow and temperature distribution differ between drying ovens and muffle furnaces? Key Insights for Lab Efficiency

- How does a high-temperature muffle furnace facilitate the formation of the Sr2TiO4 semiconductor structure?