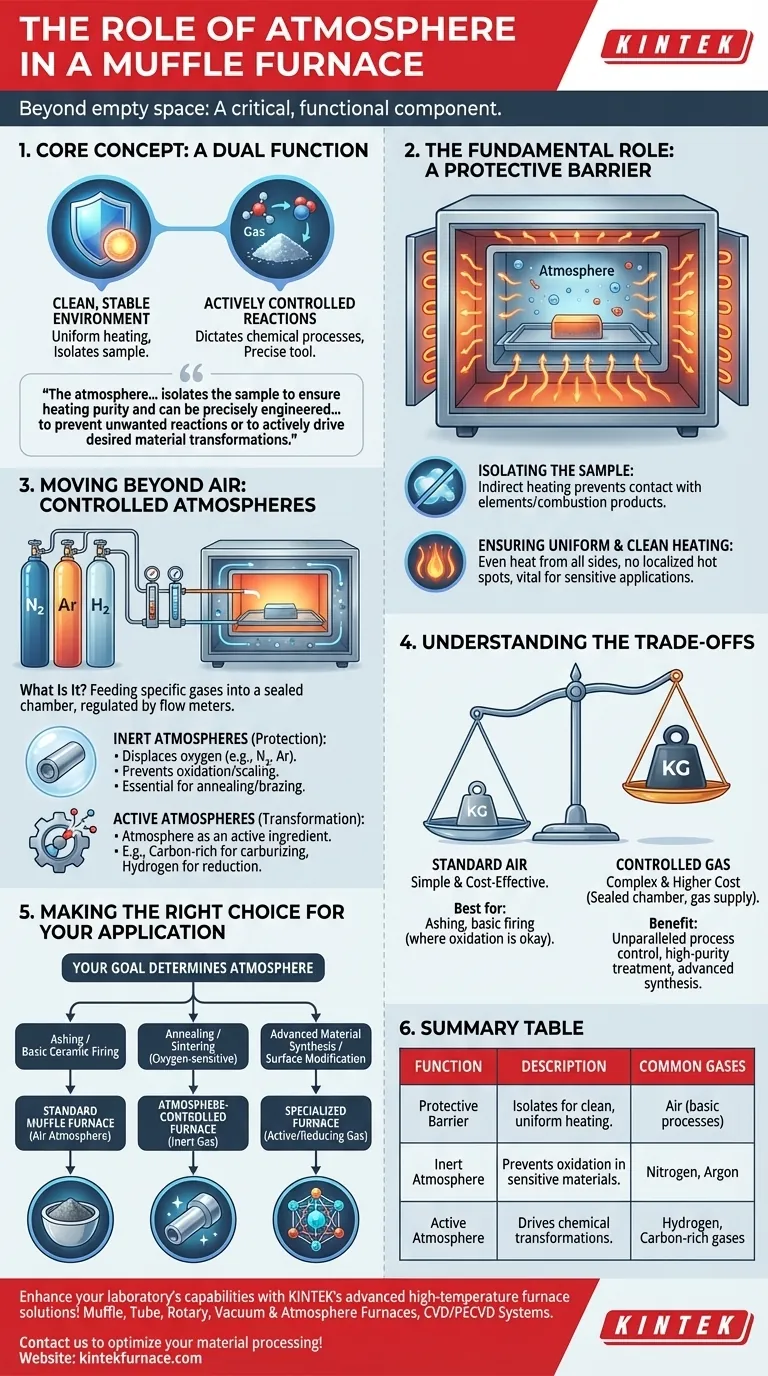

At its core, the atmosphere in a muffle furnace serves a dual function: it provides a clean, stable environment for uniform heating and can be actively controlled to dictate the chemical reactions that occur during the process. It transforms the furnace from a simple oven into a precise materials processing tool.

The atmosphere inside a muffle furnace is not merely empty space; it is a critical, functional component. It isolates the sample to ensure heating purity and can be precisely engineered with specific gases to either prevent unwanted reactions like oxidation or to actively drive desired material transformations.

The Fundamental Role: A Protective Barrier

A muffle furnace is defined by its design, which separates the sample from the heating source. The atmosphere within this "muffle," or chamber, is central to how this design functions.

Isolating the Sample

The furnace operates by passing electricity through high-resistance heating elements, which generate intense heat. These elements are outside the primary chamber.

The atmosphere—whether it is simple air or a specific gas—fills the chamber and transfers this heat to the sample through convection and radiation. This indirect heating method prevents any direct contact with the heating elements or, in older fuel-fired designs, any products of combustion.

Ensuring Uniform and Clean Heating

This separation is critical for process purity. The controlled atmosphere ensures the sample is heated evenly from all sides without localized "hot spots" from direct exposure to a glowing element.

This method guarantees that the only thing interacting with the sample is the controlled temperature and the surrounding atmosphere, which is vital for sensitive applications.

Moving Beyond Air: Controlled Atmospheres

While many processes simply use the ambient air as the atmosphere, the true power of a muffle furnace is realized when you actively manage the atmospheric composition. This is done by purging the air and injecting specific gases.

What Is a Controlled Atmosphere?

A controlled atmosphere is created by feeding specific gases, like nitrogen, argon, or hydrogen, into the sealed furnace chamber.

Gas flow meters are used to regulate the flow rate precisely, ensuring the desired atmospheric composition remains stable throughout the heating and cooling cycle.

Inert Atmospheres for Protection

For many materials, heating them in the presence of oxygen is destructive, causing unwanted oxidation, scaling, or burning.

Injecting an inert gas like argon or nitrogen displaces the oxygen, creating a non-reactive environment. This is essential for processes like annealing or brazing sensitive metals, where maintaining the material's surface purity is paramount.

Active Atmospheres for Transformation

In more advanced applications, the atmosphere becomes an active ingredient in the chemical process.

Gases can be chosen to intentionally react with the sample. For example, a carbon-rich atmosphere can be used for carburizing steel to harden its surface, while a hydrogen atmosphere can be used to reduce metal oxides back to their pure metallic form.

Understanding the Trade-offs

The choice of atmosphere directly impacts the complexity, cost, and outcome of your process. Understanding the trade-offs is key to proper application.

Standard Air Atmosphere

Using air is the simplest and most cost-effective method. It is the standard for processes where oxidation is either desired or irrelevant.

A prime example is ashing, where a sample is burned completely in the presence of oxygen to measure its inorganic content. However, for most metals at high temperatures, an air atmosphere is detrimental.

Controlled Gas Atmosphere

Implementing a controlled atmosphere adds complexity and cost, requiring a sealed chamber, gas supply, and monitoring equipment.

The benefit is unparalleled process control. It enables the high-purity heat treatment of reactive materials and allows for advanced material synthesis and surface modification that would be impossible in air.

Making the Right Choice for Your Application

Your goal determines the atmospheric requirements. The furnace and its atmosphere must be selected to match the specific material processing task.

- If your primary focus is ashing or basic ceramic firing: A standard muffle furnace with a simple air atmosphere is sufficient and correct for the task.

- If your primary focus is annealing or sintering oxygen-sensitive materials: An atmosphere-controlled furnace capable of maintaining an inert gas environment (like nitrogen or argon) is essential.

- If your primary focus is advanced material synthesis or surface modification: You need a specialized furnace with precise gas flow control to create active or reducing atmospheres.

Ultimately, the atmosphere inside a muffle furnace should be viewed as an active tool that dictates the success of your thermal process.

Summary Table:

| Function | Description | Common Gases Used |

|---|---|---|

| Protective Barrier | Isolates samples for clean, uniform heating without contamination | Air (for basic processes) |

| Inert Atmosphere | Prevents oxidation and unwanted reactions in sensitive materials | Nitrogen, Argon |

| Active Atmosphere | Drives chemical transformations like carburizing or reduction | Hydrogen, Carbon-rich gases |

Enhance your laboratory's capabilities with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse labs with precision tools like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we meet your unique experimental needs. Contact us today to discuss how our furnaces can optimize your material processing and drive innovation!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the role of a muffle furnace in the synthesis of water-soluble Sr3Al2O6? Precision in SAO Production

- What substances are prohibited from being introduced into the furnace chamber? Prevent Catastrophic Failure

- What is the role of a muffle furnace in the study of biochar regeneration and reuse? Unlock Sustainable Water Treatment

- What is the key role of a muffle furnace in the pretreatment of boron sludge and szaibelyite? Unlock Higher Process Efficiency

- What role does a muffle furnace play in the preparation of MgO support materials? Master Catalyst Activation