At their core, box type resistance furnaces are versatile workhorses used across a remarkable range of industrial, research, and environmental fields. Their key applications include heat-treating metals through processes like quenching and annealing, sintering advanced ceramics, forming glass components, and preparing samples in laboratory settings.

A box furnace’s true value lies not just in its wide range of applications, but in its fundamental design. It delivers a reliable, uniform, and precisely controlled high-temperature environment with operational simplicity, making it an indispensable tool for any process requiring consistent thermal treatment.

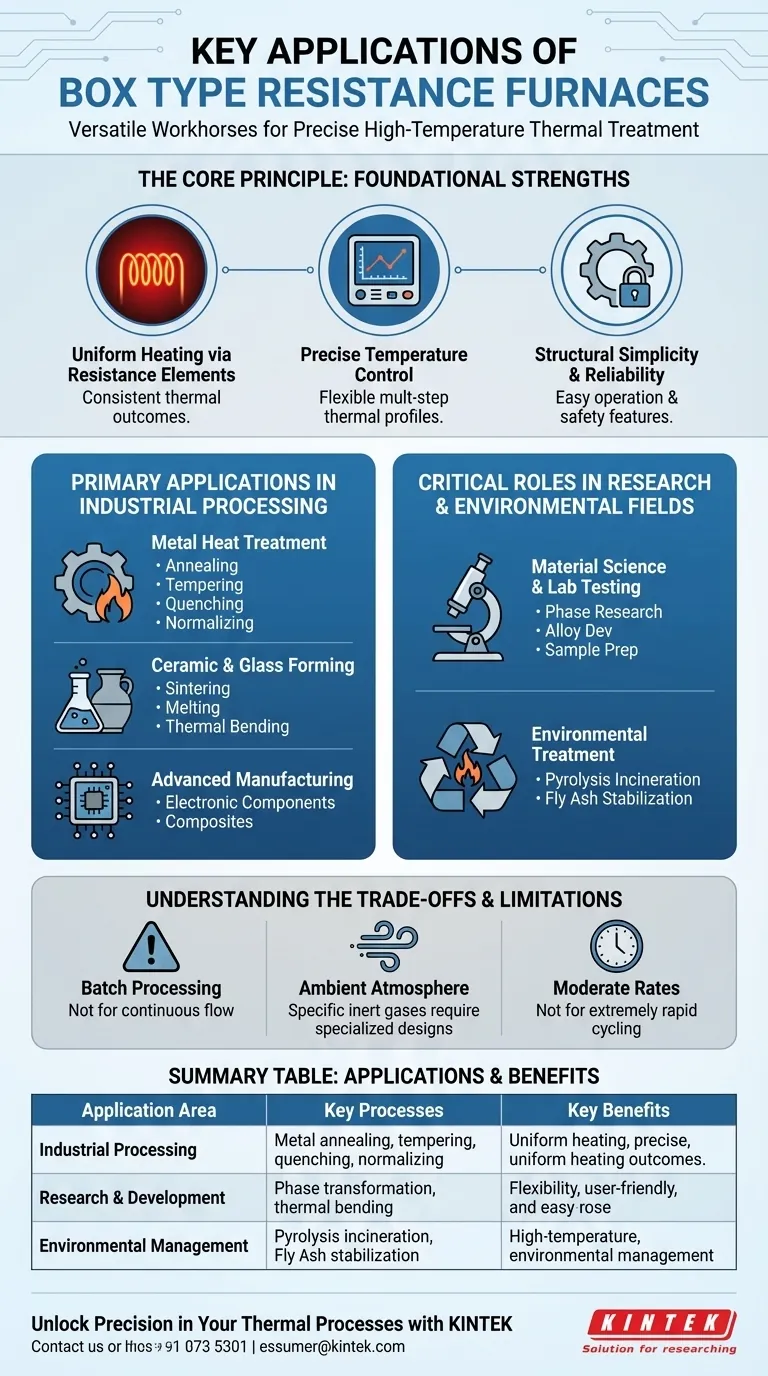

The Core Principle: Why Box Furnaces Are So Versatile

To understand the applications, you must first understand the furnace's foundational strengths. Its "universal" nature comes from a combination of three key attributes.

Uniform Heating via Resistance Elements

A box furnace uses electrical resistance wires as its heating elements. These elements are strategically placed within an insulated chamber to generate and radiate heat.

This design ensures the entire workspace, and the material within it, reaches the target temperature with high uniformity, which is critical for consistent process outcomes.

Precise Temperature Control

Modern box furnaces are equipped with user-friendly digital controllers. This allows operators to easily set and maintain specific temperatures or program multi-step thermal profiles (ramping, soaking, and cooling).

This flexible and precise control is what makes the furnace adaptable to the distinct requirements of different materials and processes, from slowly annealing steel to rapidly firing a ceramic.

Structural Simplicity and Reliability

The design is straightforward: an insulated box, heating elements, and a control system. This simplicity makes them easy to operate after minimal training.

Furthermore, they are built for reliability and safety, typically including features like over-temperature alarms and leakage protection to safeguard both the operator and the equipment.

Primary Applications in Industrial Processing

The furnace's reliable heating makes it a staple in many production environments.

Metal Heat Treatment

This is a primary application where precise temperature control is used to alter a metal's physical and mechanical properties. Key processes include:

- Annealing: Softening metals to improve ductility.

- Tempering: Reducing the brittleness of hardened steel.

- Quenching: Rapidly cooling metal to harden it.

- Normalizing: Refining the grain structure of steel.

- Solid Solution Treatment: Homogenizing alloys, such as nickel-based superalloys for aerospace.

Ceramic and Glass Forming

High temperatures are essential for processing ceramics and glass. The furnace provides the controlled environment needed for these delicate tasks. Key processes include:

- Sintering: Firing compacted ceramic powders (like alumina) to create a dense, solid part.

- Melting and Firing: Used in the production of various glass and ceramic products.

- Thermal Bending: Heating glass, such as for 3D mobile phone covers, until it is pliable enough to be formed into a specific shape.

Advanced Manufacturing

The furnace also plays a role in creating high-tech materials and components. Key processes include:

- Electronic Component Manufacturing: Firing materials to create components like resistors and capacitors.

- Composite Material Processing: This includes steps like the pre-oxidation of carbon fibers or the sintering of ceramic-matrix composites (CMCs).

Critical Roles in Research and Environmental Fields

Beyond the factory floor, box furnaces are essential tools for discovery and remediation.

Material Science and Laboratory Testing

For researchers, the box furnace is a fundamental tool for experimentation and sample preparation. Its flexibility allows for a wide range of tests. Key uses include:

- Phase Transformation Research: Observing how a material's crystal structure changes with heat.

- Alloy Development: Creating and testing new metallic alloys.

- General Sample Preparation: Heating materials to a known state before further analysis.

Environmental Treatment and Waste Management

The high-temperature capability of these furnaces is leveraged for treating hazardous waste. Key uses include:

- Pyrolysis Incineration: Decomposing medical waste at temperatures above 850°C for harmless disposal.

- Fly Ash Stabilization: Melting industrial fly ash at high temperatures to trap heavy metals within a stable, glassy matrix, preventing them from leaching into the environment.

Understanding the Trade-offs

While incredibly versatile, the box furnace is not the optimal solution for every thermal challenge. Understanding its limitations is key to using it effectively.

Batch Processing vs. Continuous Flow

A box furnace is inherently a batch processing tool. You load it, run a cycle, and unload it. It is not designed for continuous, high-volume production lines where parts move constantly through a heating zone.

Atmosphere Considerations

A standard box furnace operates in ambient air. Processes that require a specific inert gas atmosphere (like argon) or a vacuum to prevent oxidation require specialized and more complex furnace designs.

Moderate Heating and Cooling Rates

Due to its insulated structure and thermal mass, a box furnace has moderate heating and cooling rates. For applications requiring extremely rapid thermal cycling, other specialized equipment like a rapid thermal processing (RTP) system would be more appropriate.

Making the Right Choice for Your Goal

To apply this knowledge, match the furnace's capabilities to your primary objective.

- If your primary focus is repeatable metallurgical properties: Use the furnace's uniform heating for consistent results in annealing, tempering, and normalizing.

- If your primary focus is materials research and development: Leverage its flexibility and precise control to test new materials, study phase transformations, and prepare samples.

- If your primary focus is high-temperature processing: Utilize its capability for ceramic sintering, glass melting, or specialized waste treatment like pyrolysis.

Ultimately, the box resistance furnace excels by providing a straightforward and dependable solution for a vast array of thermal processing challenges.

Summary Table:

| Application Area | Key Processes | Key Benefits |

|---|---|---|

| Industrial Processing | Metal annealing, tempering; Ceramic sintering; Glass forming | Uniform heating, precise temperature control, reliability |

| Research & Development | Phase transformation studies, alloy development, sample preparation | Flexibility, user-friendly controls, consistent results |

| Environmental Management | Pyrolysis incineration, fly ash stabilization | High-temperature capability, safety features |

| Limitations | Batch processing, ambient atmosphere, moderate heating/cooling rates | Not suitable for continuous flow or rapid cycling |

Unlock Precision in Your Thermal Processes with KINTEK

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Whether you're in industrial processing, materials research, or environmental management, our furnaces deliver uniform heating, precise control, and reliability to enhance your outcomes.

Contact us today to discuss how KINTEK can tailor a solution for your specific needs and boost your efficiency!

Visual Guide

Related Products

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- How does sample handling differ between vertical and horizontal tube furnaces? Choose the Right Furnace for Your Lab

- What is the use of a quartz tube furnace? For High-Purity, Observable Material Processing

- How does the quartz tube furnace minimize heat loss? Double Insulation for Energy Efficiency

- What are the key features of a quartz tube furnace? Discover High-Temp Precision for Your Lab

- What are the common applications of quartz tube furnaces? Unlock Precision in High-Temp Processing