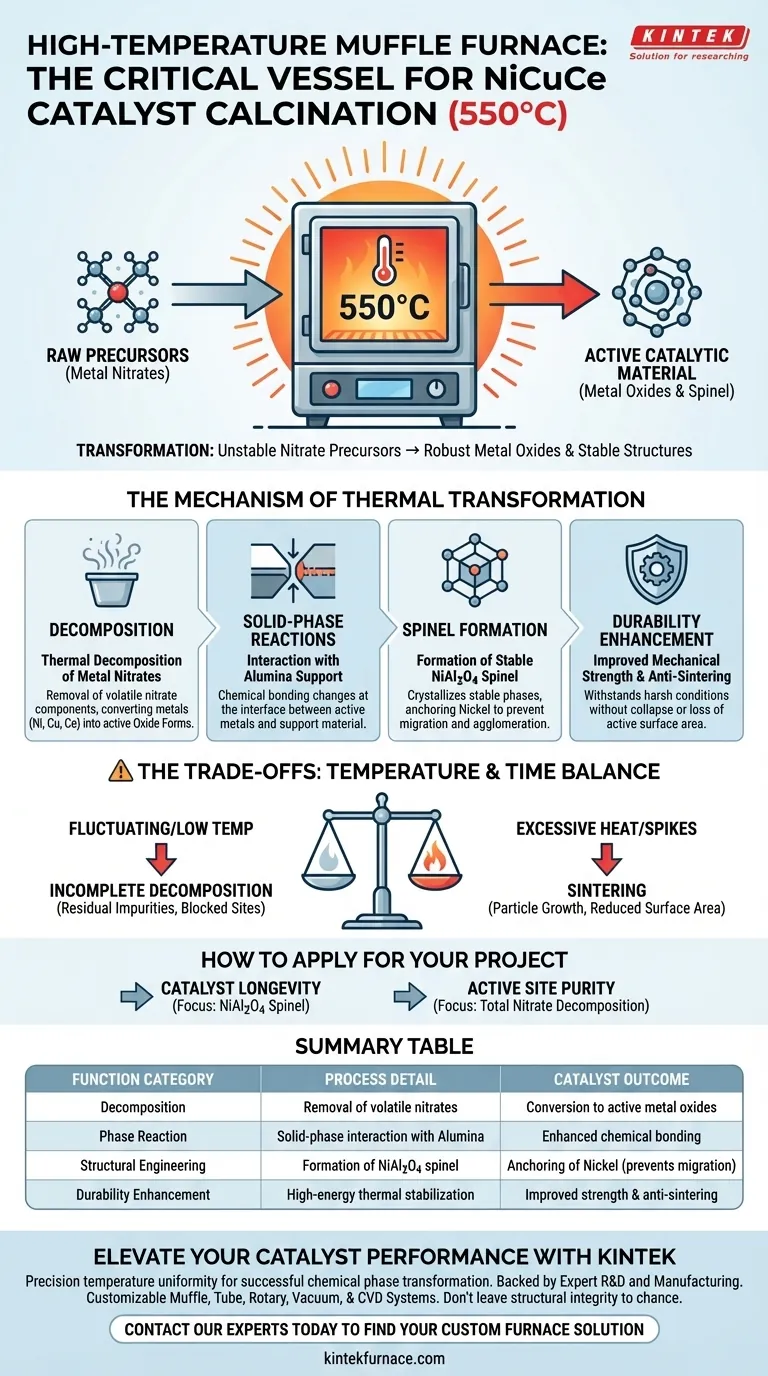

The high-temperature muffle furnace acts as the critical vessel for chemical phase transformation, converting raw precursors into active catalytic material. Specifically, at 550 degrees Celsius, this equipment facilitates the thermal decomposition of loaded metal nitrates into their oxide forms while simultaneously engineering the catalyst's structural integrity.

The primary function of this thermal treatment is to induce a transition from unstable nitrate precursors to robust metal oxides. Beyond simple decomposition, this process drives solid-phase reactions that anchor active metals to the support, significantly enhancing the catalyst's resistance to thermal degradation.

The Mechanism of Thermal Transformation

Decomposition of Metal Precursors

The immediate function of the muffle furnace at this temperature is to drive the thermal decomposition of metal nitrates.

By maintaining a consistent 550°C environment, the furnace ensures that volatile nitrate components are fully removed. This converts the loaded metals (Nickel, Copper, and Cerium) from their precursor salt forms into their respective, chemically active oxide forms.

Inducing Solid-Phase Reactions

Beyond decomposition, the heat treatment initiates essential solid-phase reactions between the active metals and the support material.

In the context of NiCuCe catalysts, this thermal energy allows the metal species to interact chemically with the alumina support. This interaction is not merely physical; it changes the chemical bonding at the interface of the materials.

Formation of Stable Spinel Structures

A critical outcome of these solid-phase reactions is the formation of stable crystalline structures, specifically NiAl2O4 spinel.

The muffle furnace provides the sustained energy required to crystallize these phases. The formation of the NiAl2O4 spinel structure is vital because it anchors the Nickel, preventing it from migrating or agglomerating during operation.

Enhancing Catalyst Durability

The ultimate functional goal of this high-temperature treatment is the improvement of mechanical strength and anti-sintering capabilities.

By converting precursors to oxides and forming stable spinels, the furnace ensures the catalyst can withstand harsh operating conditions without structurally collapsing or losing active surface area.

Understanding the Trade-offs

The Balance of Temperature and Time

While 550°C is targeted for these specific reactions, deviations in the furnace environment can lead to suboptimal results.

If the temperature fluctuates or is too low, incomplete decomposition of the nitrates may occur, leaving residual impurities that block active sites. Conversely, excessive heat or uncontrolled spikes can accelerate sintering, causing metal particles to grow too large and reducing the overall surface area available for catalysis.

How to Apply This to Your Project

To maximize the efficacy of your NiCuCe catalyst preparation, consider the following strategic focus areas:

- If your primary focus is catalyst longevity: Prioritize the precise maintenance of 550°C to ensure the complete formation of the NiAl2O4 spinel, which provides the necessary anti-sintering resistance.

- If your primary focus is active site purity: Ensure adequate airflow and duration within the muffle furnace to guarantee the total thermal decomposition of all nitrate precursors into oxides.

The muffle furnace is not just a heating element; it is the tool that determines the structural destiny and long-term viability of your catalytic material.

Summary Table:

| Function Category | Process Detail | Catalyst Outcome |

|---|---|---|

| Decomposition | Removal of volatile nitrate components | Conversion of precursors to active metal oxides |

| Phase Reaction | Solid-phase interaction with Alumina support | Enhanced chemical bonding at material interfaces |

| Structural Engineering | Formation of NiAl2O4 spinel crystalline structure | Anchoring of Nickel to prevent migration/agglomeration |

| Durability Enhancement | High-energy thermal stabilization | Improved mechanical strength and anti-sintering capability |

Elevate Your Catalyst Performance with KINTEK

Precision is the difference between a successful chemical phase transformation and a failed batch. At KINTEK, we understand that your research depends on exact temperature uniformity and reliability.

Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, and CVD systems, all fully customizable for your unique NiCuCe catalyst synthesis or high-temp lab needs. Don't leave your structural integrity to chance—partner with the leaders in lab thermal processing.

Contact Our Experts Today to Find Your Custom Furnace Solution

Visual Guide

References

- Yankun Jiang, Siqi Li. Sustainable Hydrogen from Methanol: NiCuCe Catalyst Design with CO2-Driven Regeneration for Carbon-Neutral Energy Systems. DOI: 10.3390/catal15050478

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What are the primary uses of muffle furnaces in the pharmaceutical industry? Ensure Drug Purity and Stability

- What warranty and support are provided with the muffle furnace? Understand Coverage and Exclusions

- What optional systems are available for Box Furnaces? Enhance Your Thermal Process with Custom Solutions

- What steps should be taken after completing an experiment with a muffle furnace? Ensure Safety and Equipment Longevity

- How are muffle furnaces used in the pharmaceutical industry? Essential for Quality Control and R&D

- What is the temperature of a muffle furnace? Find Your Ideal Range (300°C to 1800°C+)

- What is the function of a Muffle Furnace in the LSS process for MXene synthesis? Achieve Low-Temp Precision

- What is the chamber of the box furnace made of and how are heating elements arranged? Optimize Your Lab's Heat Processing